Determination of the average size of preliminary grinded wet feed particles in hammer grinders

DOI:

https://doi.org/10.15587/1729-4061.2023.268519Keywords:

length of grinded particles, hammer working body, hammers, hammer spacingAbstract

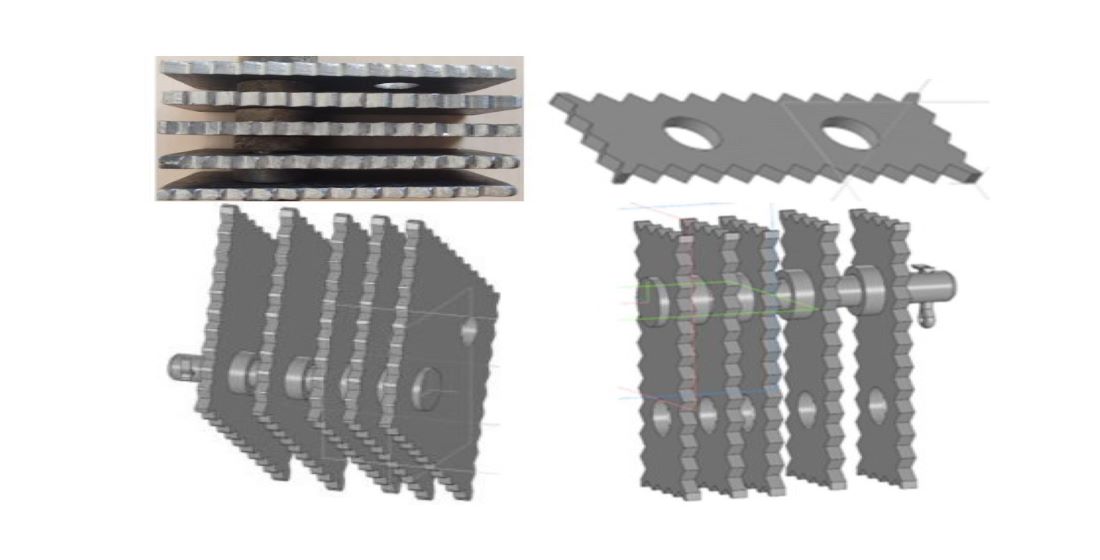

In the conditions of farms, it becomes necessary to grind feed that has a different degree of moisture. Therefore, the choice of universal working bodies is the object of research, and the theoretical determination of the average size of pre-crushed feed particles is of great scientific and practical importance and is a problem that needs to be solved. Proceeding from this, a constructive-technological scheme of a grinder with a universal grinding working body is proposed. The grinding apparatus is equipped with a hammer working body which has cutting edges. In this case, hammers with cutting edges crush the wet mass, and also create an air flow and work as flow accelerators at high speed. As a result of theoretical studies, the steps for arranging these working bodies were determined. Analytical expressions are obtained for determining the average length of pre-crushed feed particles depending on the distance between the faces of replaceable knife working bodies, i.e. from the step of arranging them in rows. At the same time, the calculation results showed that with a distance between the faces of replaceable hammers of 20 mm, the value of the average length of the grinded particles was 38.38 mm. The average size of pre-crushed particles from feed raw materials intended for farm animals was 37.64 mm, i. e. the difference between theoretical and actual value is only 2.0 %. This proves the reliability of the obtained analytical expression, which provides the determination of the main parameter of the grinding working body, i. e. spacing of radial knives in rows. The proposed method of determining the average length of crushed particles allows theoretically finding and planning the required particle size

Supporting Agency

- This research has been/was/is funded by the Science Committee of the Ministry of Education and Science of the Republic of Kazakhstan (Grant No. AP09259673).

References

- Iskakov, R. M., Iskakova, A. M., Issenov, S. S., Beisebekova, D. M., Khaimuldinova, A. K. (2019). Technology of Multi-stage Sterilization of Raw Materials with the Production of Feed Meal of High Biological Value. Journal of Pure and Applied Microbiology, 13 (1), 307–312. doi: https://doi.org/10.22207/jpam.13.1.33

- Iskakov, R. M., Issenov, S. S., Iskakova, A. M., Halam, S., Beisebekova, D. M. (2015). Microbiological Appraisal of Feed Meal of Animal Origin, Produced by Drying and Grinding Installation. Journal of Pure and Applied Microbiology, 9 (1), 587–592.

- Zeng, Y., Forssberg, E. (1992). Effects of mill feed size and rod charges on grinding performance. Powder Technology, 69 (2), 119–123. doi: https://doi.org/10.1016/0032-5910(92)85064-3

- Chkalova, M., Pavlidis, V. (2021). Assessment of equipment efficiency in models of technological processes for production of combined feed. Engineering for Rural Development. doi: https://doi.org/10.22616/erdev.2021.20.tf193

- Leiva, A., Granados-Chinchilla, F., Redondo-Solano, M., Arrieta-González, M., Pineda-Salazar, E., Molina, A. (2018). Characterization of the animal by-product meal industry in Costa Rica: Manufacturing practices through the production chain and food safety. Poultry Science, 97 (6), 2159–2169. doi: https://doi.org/10.3382/ps/pey058

- Hesch, C., Weinberg, K. (2014). Thermodynamically consistent algorithms for a finite-deformation phase-field approach to fracture. International Journal for Numerical Methods in Engineering, 99 (12), 906–924. doi: https://doi.org/10.1002/nme.4709

- Lee, C. H., Gil, A. J., Ghavamian, A., Bonet, J. (2019). A Total Lagrangian upwind Smooth Particle Hydrodynamics algorithm for large strain explicit solid dynamics. Computer Methods in Applied Mechanics and Engineering, 344, 209–250. doi: https://doi.org/10.1016/j.cma.2018.09.033

- Bonet, J., Gil, A. J. (2021). Mathematical models of supersonic and intersonic crack propagation in linear elastodynamics. International Journal of Fracture, 229 (1), 55–75. doi: https://doi.org/10.1007/s10704-021-00541-y

- Markochev, V. M., Alymov, M. I. (2017). On the brittle fracture theory by Ya. Frenkel and A. Griffith. Chebyshevskii Sbornik, 18 (3), 381–393. doi: https://doi.org/10.22405/2226-8383-2017-18-3-381-393

- Zhou, Z.-G., Du, S.-Y., Wang, B. (2001). Investigation of Anti-plane Shear Behavior of a Griffith Crack in a Piezoelectric Material by Using the Non-local Theory. International Journal of Fracture, 111 (2), 105–117. doi: https://doi.org/10.1023/A:1012201923151

- Liu, B., Zhang, D. X., Zong, L. (2010). Investigation on the Motion States of the Hammers while Hammer Mill Steady Running by High-Speed Photography. Applied Mechanics and Materials, 42, 317–321. doi: https://doi.org/10.4028/www.scientific.net/amm.42.317

- Akbari, M. J., Kazemi, S. R. (2020). Peridynamic Analysis of Cracked Beam Under Impact. Journal of Mechanics, 36 (4), 451–463. doi: https://doi.org/10.1017/jmech.2020.12

- Tang, W. Y., He, Y. S., Zhang, S. K., Yuan, M. (2005). Dynamic Buckling of Cracked Beams Subject to Axial Impacting. 15th International Offshore and Polar Engineering Conference (ISOPE 2005). Seoul, 354–359. Available at: https://onepetro.org/ISOPEIOPEC/proceedings-abstract/ISOPE05/All-ISOPE05/ISOPE-I-05-405/9537

- Georgiadis, H. G. (1987). Finite length crack moving in a viscoelastic strip under impact – I. Theory. Engineering Fracture Mechanics, 27 (5), 593–599. doi: https://doi.org/10.1016/0013-7944(87)90111-1

- Smits, M., Kronbergs, E. (2017). Determination Centre of Percussion for Hammer Mill Hammers. 16th International Scientific Conference Engineering for Rural Development. doi: http://dx.doi.org/10.22616/ERDev2017.16.N072

- Savinyh, P., Isupov, A., Ivanov, I., Ivanovs, S. (2021). Research in centrifugal rotary grinder of forage grain. Engineering for Rural Development. doi: https://doi.org/10.22616/erdev.2021.20.tf044

- Verma, H. R., Singh, K. K., Basha, S. M. (2018). Effect of Milling Parameters on the Concentration of Copper Content of Hammer-Milled Waste PCBs: A Case Study. Journal of Sustainable Metallurgy, 4 (2), 187–193. doi: https://doi.org/10.1007/s40831-018-0179-z

- Warzecha, M., Michalczyk, J. (2020). Calculation of maximal collision force in kinematic chains based on collision force impulse. Journal of Theoretical and Applied Mechanics, 58 (2), 339–349. doi: https://doi.org/10.15632/jtam-pl/116580

- Zhiltsov, A. P., Vlasenko, D. A., Levchenko, E. P. (2019). Research and Substantiation of Structural and Technological Parameters of the Process of Grinding Agglomeration Fluxes in a Hammer Mill. Chernye Metally, 10, 4–10.

- Munkhbayar, B., Bayaraa, N., Rehman, H., Kim, J., Chung, H., Jeong, H. (2012). Grinding characteristic of multi-walled carbon nanotubes-alumina composite particle. Journal of Wuhan University of Technology-Mater. Sci. Ed., 27 (6), 1009–1013. doi: https://doi.org/10.1007/s11595-012-0590-4

- Abilzhanuly, T. (2019). Method of Fineness Adjustment of Shredded Particles of Stem Fodder in Open-type Machines. EurAsian Journal of BioSciences, 13 (1), 625–631.

- Iskakov, R. М., Issenov, S. S., Iskakova, A. M., Halam, S., Beisebekova, D. M. (2013). Heat-and-Moisture Transfer at the Feed Meal Particles Drying and Grinding. Life Science Journal, 10 (12s), 497–502. Available at: http://www.lifesciencesite.com/lsj/life1012s/083_22175life1012s_497_502.pdf

- Issenov, S., Iskakov, R., Tergemes, K., Issenov, Z. (2022). Development of mathematical description of mechanical characteristics of integrated multi-motor electric drive for drying plant. Eastern-European Journal of Enterprise Technologies, 1 (8 (115)), 46–54. doi: https://doi.org/10.15587/1729-4061.2021.251232

- Iskakov, R. M., Iskakova, A. M., Nurushev, M. Z., Khaimuldinova, A. K., Karbayev, N. K. (2021). Method for the Production of Fat from Raw Materials and Animal Waste. Journal of Pure and Applied Microbiology, 15 (2), 716–724. doi: https://doi.org/10.22207/jpam.15.2.23

- Alpeissov, Y., Iskakov, R., Issenov, S., Ukenova, А. (2022). Obtaining a formula describing the interaction of fine particles with an expanding gas flow in a fluid layer. Eastern-European Journal of Enterprise Technologies, 2 (1 (116)), 87–97. doi: https://doi.org/10.15587/1729-4061.2022.255258

- Yang, J. H., Fang, H. Y., Luo, M. (2015). Load and wear experiments on the impact hammer of a vertical shaft impact crusher. IOP Conference Series: Materials Science and Engineering, 103, 012041. doi: https://doi.org/10.1088/1757-899x/103/1/012041

- Hong, S., Kim, S. (2017). Analysis of simulation result by digital filtering technique and improvement of hammer crusher. International Journal of Mineral Processing, 169, 168–175. doi: https://doi.org/10.1016/j.minpro.2017.11.004

- Kobrin, Y., Vlasov, A., Shevchenko, I. (2020). The effect of rotor balance during crushing of intermetallic compounds in hammer crushers. METAL Conference Proeedings. doi: https://doi.org/10.37904/metal.2020.3617

- Sauk, H., Selvi, K. C. (2018). Factors Affecting Energy Consumption in Hammer Mills. Scientific Papers - Series A, Agronomy, 61 (1), 392–396.

- Adigamov, N. R., Shaikhutdinov, R. R., Gimaltdinov, I. H., Akhmetzyanov, R. R., Basyrov, R. S. (2020). Determining the residual resource of the hammer crushers’ rotor bearings. BIO Web of Conferences, 17, 00239. doi: https://doi.org/10.1051/bioconf/20201700239

- Ulanov, I. A. (1976). Mashiny dlya izmel'cheniya kormov (teoriya i raschet). Saratov, 86.

- Globin, A. N. (2017). Modelirovaniye protsessa dozirovannoy vydachi izmel'chennykh stebel'nykh kormov. Vestnik agrarnoy nauki Dona, 1 (37), 5–15. Available at: https://cyberleninka.ru/article/n/modelirovanie-protsessa-dozirovannoy-vydachi-izmelchennyh-stebelnyh-kormov

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Tokhtar Abilzhanuly, Ruslan Iskakov, Daniyar Abilzhanov, Orazakhin Darkhan

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.