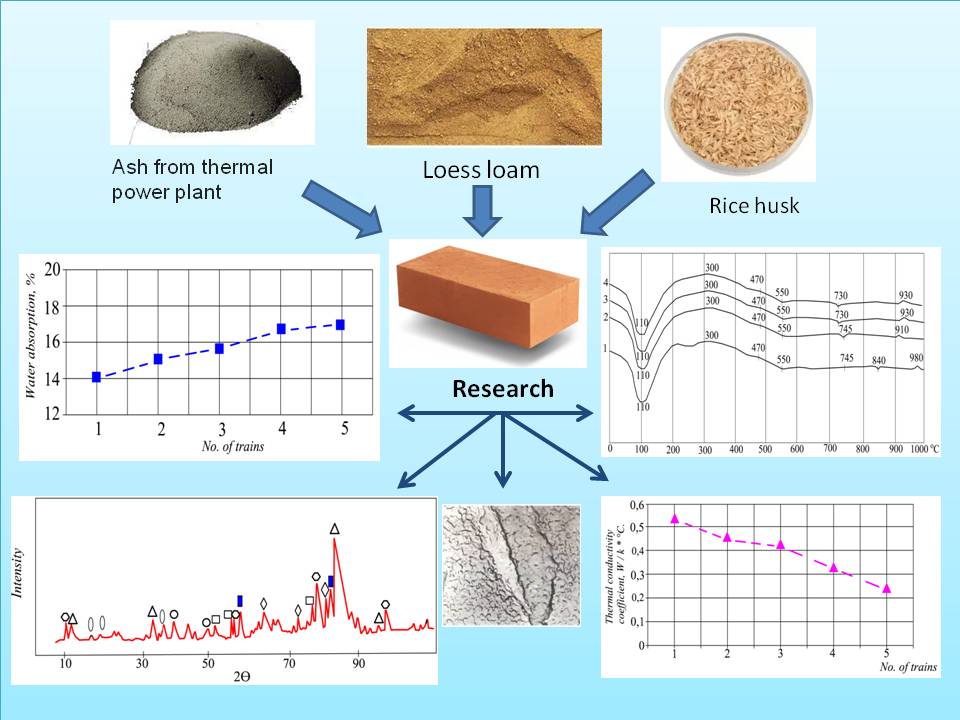

Physical and mechanical properties of ceramic brick using rice husk and ash of thermal power plants

DOI:

https://doi.org/10.15587/1729-4061.2022.269124Keywords:

ceramic brick, rice husk, ash, shrinkage deformations, technology, thermal conductivityAbstract

The paper presents the results of the influence on shrinkage deformations of the adopted composition during the drying and firing of ceramic bricks made using rice husk and ash of the combined heat and power plant of the city of Kyzylorda of the Republic of Kazakhstan.

The optimal values of the husk additives content and ash from thermal power plants in the studied compositions were determined. Ash dumps from thermal power plants (TPP) create environmental tension and pose a great threat to both the environment and human health. It was found that the hydro-removal ash from the thermal power plant mainly consists of oxides of silica (45.45…46.37 %) and alumina (16.62…17.70 %), there are oxides of calcium (1.66…2.20 %), magnesium (0.86…1.12 %), iron (2.98…3.41 %) and alkali metals (0.80…1.04 %).

The composition of ceramic bricks based on loess-like loam, rice husks, and ash from thermal power plants was studied. The charge composition of the raw components of the “clay, TPP ash, and rice husk” brick: clay is 71…75 %, TPP ash is 18…22 %, and rice husk is 2…6 % of the total mass of the components of the raw mixture of ceramic bricks. The compressive strength of fired ceramic bricks was 11…12 MPa.

According to the results of experimental studies, it was found that the increased concentration of rice husks in natural mixtures is characterized by a stable increase in ceramic mass drying cracks. The increase in time until the appearance of drying cracks is 100 up to 160 sec.

The resulting ceramic brick in accordance with the developed composition has a low weight, good thermal properties and meets the standard requirements for ceramic bricks according to GOST 530-2012

References

- Jafarinejad, S. (2017). Solid-Waste Management in the Petroleum Industry. Petroleum Waste Treatment and Pollution Control, 269–345. doi: https://doi.org/10.1016/b978-0-12-809243-9.00007-9

- Ketov, A., Korotaev, V., Rudakova, L., Vaisman, I., Barbieri, L., Lancellotti, I. (2020). Amorphous silica wastes for reusing in highly porous ceramics. International Journal of Applied Ceramic Technology, 18 (2), 394–404. doi: https://doi.org/10.1111/ijac.13654

- Al-Fakih, A., Mohammed, B. S., Liew, M. S., Nikbakht, E. (2019). Incorporation of waste materials in the manufacture of masonry bricks: An update review. Journal of Building Engineering, 21, 37–54. doi: https://doi.org/10.1016/j.jobe.2018.09.023

- Vamsi Krishna, B., Rakesh Reddy, E. (2018). Applications of green materials for the preparation of eco-friendly bricks and pavers. International Journal of Engineering & Technology, 7 (3.29), 75. doi: https://doi.org/10.14419/ijet.v7i3.29.18465

- Sutas, J., Mana, A., Pitak, L. (2012). Effect of Rice Husk and Rice Husk Ash to Properties of Bricks. Procedia Engineering, 32, 1061–1067. doi: https://doi.org/10.1016/j.proeng.2012.02.055

- Naganathan, S., Mohamed, A. Y. O., Mustapha, K. N. (2015). Performance of bricks made using fly ash and bottom ash. Construction and Building Materials, 96, 576–580. doi: https://doi.org/10.1016/j.conbuildmat.2015.08.068

- Adylov, D. K., Bekturdiev, G. M., Yusupov, F. M., Kim, R. N. (2011). The Method for Agricultural Waste Recycling to Obtain Modified Fibre for Use in Asbestos-Cement Production. Cooperation to solve the problem of waste: Mat. VIII Intern. Conf. Kharkiv. Available at: https://waste.ua/cooperation/2011/Theses/adylov.html

- Vinogradov, V. V., Bylkov, A. A., Vinogradov, D. V. (1999). Pat. No. 2171780 RF. Technological module for complex processing of rice husks. declareted: 10.05.1999; published: 08.10.2001. Available at: https://findpatent.ru/patent/217/2171780.html

- Gameliak, I., Dmytrychenko, A., Tsybulskyi, V., Kharchenko, A. (2022). Determining the effect of reinforcing a cement-concrete coating of bridges on the stressed-strained state of structures. Eastern-European Journal of Enterprise Technologies, 1 (7 (115)), 21–31. doi: https://doi.org/10.15587/1729-4061.2022.251189

- Аtyaksheva, А., Rozhkova, O., Sarsikeyev, Y., Atyaksheva, A., Yermekov, M., Smagulov, A., Ryvkina, N. (2022). Determination of rational parameters for heat treatment of concrete mixture based on a hollow aluminosilicate microsphere. Eastern-European Journal of Enterprise Technologies, 1 (6 (115)), 64–72. doi: https://doi.org/10.15587/1729-4061.2022.251004

- Suryadi, A., Qomariah, Q., Susilo, S. H. (2022). The effect of the use of recycled coarse aggregate on the performance of self-compacting concrete (SCC) and its application. Eastern-European Journal of Enterprise Technologies, 2 (6 (116)), 41–47. doi: https://doi.org/10.15587/1729-4061.2022.255266

- Uderbayev, S. S., Bissenov, K. A., Saktaganova, N. A., Mashkin, N. A., Dunaev, I. S. (2021). Microclimate in the buildings from volume blocks. NEWS of the Academy of Sciences of the Republic of Kazakhstan Series of Geology and Technical Sciences, 1 (445), 186–193. doi: https://doi.org/10.32014/2021.2518-170x.26

- Vurasko, A. V., Driker, B. N., Mozyreva, E. A., Zemnukhova, L. A., Galimova, A. R., Gulemina, N. N. (2006). Resource-saving technology for the production of cellulose materials in the processing of agricultural waste. Chemistry of plant raw materials, 4, 5–10.

- Vurasko, A. V., Driker, B. N., Galimova, A. R., Mertin, E. V., Chistyakova, K. N. (2010). Pat. No. 2418122 RF. Method for producing cellulose from rice straw. No. 2010118642/12; declareted: 05.07.2010; published: 05.10.2011. Available at: https://www.freepatent.ru/patents/2418122

- Dobzhansky, V. G., Zemnukhova, L. A., Sergienko, V. I. (1996). Pat. No. 2106304 RF. A method for obtaining water-soluble silicates from rice husk ash. declareted: 23.09.1996; published: 03.10.1998. Available at: https://www.freepatent.ru/patents/2106304

- Govindarao, V. M. H. (1980). Utilization of rice husk - A preliminary analysis. J. Sci. & Ind. Res., 39 (9), 495–515. Available at: https://www.osti.gov/etdeweb/biblio/6742193

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Saken Uderbayev, Aizhan Dilmanova, Nargul Saktaganova, Aigul Budikova, Yerik Bessimbayev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.