Development of the recipe composition of gluten-free flour confectionery products based on chickpea flour

DOI:

https://doi.org/10.15587/1729-4061.2022.269397Keywords:

leguminous crops, chickpeas, rice, amaranth flour, gluten-free products, optimization of recipesAbstract

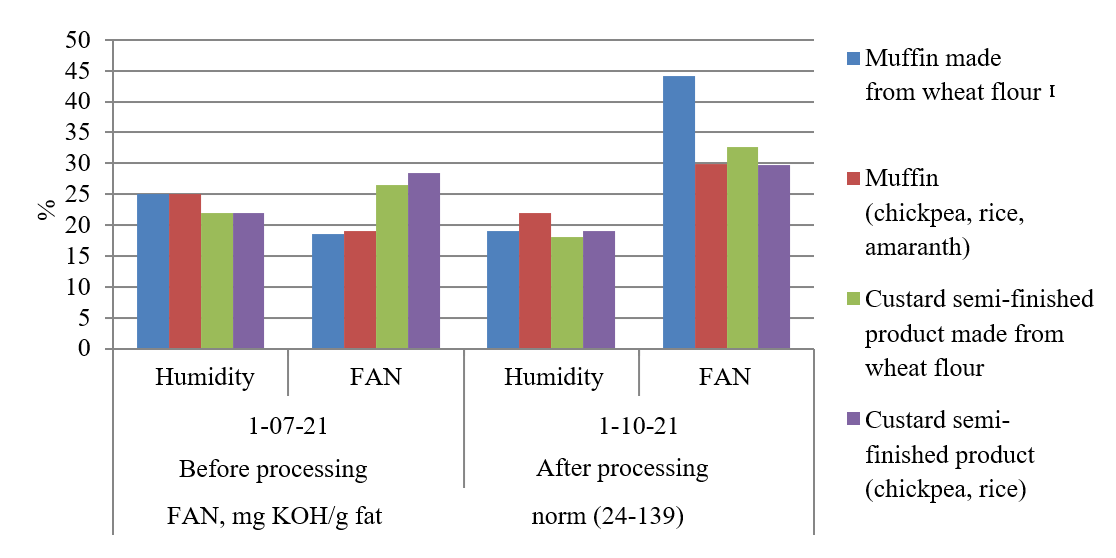

The object of this study was gluten-free flour confectionery. In order to improve the structure of the assortment and create products for specialized purposes, the hypothesis was tested that ultra-high-frequency processing can help reduce the microbiological contamination of raw materials and improve the organoleptic characteristics of finished products. For this purpose, recipes for gluten-free flour confectionery products were developed, making it possible to obtain the best values of the specific volume of finished products – custard semi-finished products and gluten-free cupcake. Based on the implementation of second-order rotatable plans, regression models were built, and the resulting response surfaces were transformed to the canonical form. Based on this, it was established that the rational ratios of the components of the cupcake in the formulation are: 80 % flour from ultra-high-frequency processed chickpea flour, 15 % rice, and 5 % amaranth flour. The ratio of components of the custard semi-finished product from ultra-high-frequency processed chickpea flour and corn flour was approximately 50:50 %.

Prototypes of gluten-free flour confectionery products were produced, and the main quality indicators were determined. It was found that when flour from ultra-high-frequency processed chickpeas was introduced into the recipe of a cupcake from rice and amaranth flour, the amount of limiting amino acid lysine increased by 1.08 times compared to unprocessed chickpea flour. In the custard semi-finished product, the amount of the limiting amino acid arginine increased by 1.97 times compared to unprocessed chickpea flour. In general, the biological value of enriched cupcake and custard semi-finished product on average exceeds the control sample by 1.5 times.

In terms of safety, the developed gluten-free flour confectionery products meet the requirements of regulatory documentation.

References

- Bozhko, S. D., Ershova, T. A., Chernyshova, A. N., Tekut'eva, L. A., Son, O. M., Podvolotskaya, A. B. (2015). Razrabotka bezglyutenovyh produktov s dlitel'nymi srokami godnosti. Sektsiya - Innovatsionnye podhody k razvitiyu tekhniki i tekhnologiy. V kn.: Innovatsionnye podhody k razvitiyu tekhniki i tekhnologiy. Muscow: Odessa. Available at: https://sworld.education/simpoz5/39.pdf

- Knyazeva, S. P., Meleshkina, L. E. (2011). Issledovanie reologicheskih harakteristik testovyh mass dlya bezglyutenovyh muchnyh kulinarnyh izdeliy. Polzunovskiy al'manah, 4-2.

- Salovaara, H., Loponen, J., Kanerva, P., Sontag-Strohm, T., Luoto, S. (Eds.) (2010). Book of Abstracts: 2nd International Symposium of Gluten-free Cereal Products and Beverages. Tampere.

- Dmitrieva, Yu. A., Zaharova, I. N. et al. (2021). Rol' i mesto bezglyutenovoy diety v pitanii detey. Praktika pediatra, 1, 17–25. Available at: https://medi.ru/docplus/pp2021-1-17.pdf

- Schmelter, L., Rohm, H., Struck, S. (2021). Gluten-free bakery products: Cookies made from different Vicia faba bean varieties. Future Foods, 4, 100038. doi: https://doi.org/10.1016/j.fufo.2021.100038

- Di Cairano, M., Condelli, N., Cela, N., Sportiello, L., Caruso, M. C., Galgano, F. (2022). Formulation of gluten-free biscuits with reduced glycaemic index: Focus on in vitro glucose release, physical and sensory properties. LWT, 154, 112654. doi: https://doi.org/10.1016/j.lwt.2021.112654

- Nasabi, M., Naderi, B., Akbari, M., Aktar, T., Kieliszek, M., Amini, M. (2021). Physical, structural and sensory properties of wafer batter and wafer sheets influenced by various sources of grains. LWT, 149, 111826. doi: https://doi.org/10.1016/j.lwt.2021.111826

- Brites, L. T. G. F., Schmiele, M., Steel, C. J. (2018). Gluten-Free Bakery and Pasta Products. Alternative and Replacement Foods, 385–410. doi: https://doi.org/10.1016/b978-0-12-811446-9.00013-7

- Naseer, B., Naik, H. R., Hussain, S. Z., Zargar, I., Beenish, Bhat, T. A., Nazir, N. (2021). Effect of carboxymethyl cellulose and baking conditions on in-vitro starch digestibility and physico-textural characteristics of low glycemic index gluten-free rice cookies. LWT, 141, 110885. doi: https://doi.org/10.1016/j.lwt.2021.110885

- Rodriguez-Garcia, J., Ding, R., Nguyen, T. H. T., Grasso, S., Chatzifragkou, A., Methven, L. (2022). Soluble fibres as sucrose replacers: Effects on physical and sensory properties of sugar-reduced short-dough biscuits. LWT, 167, 113837. doi: https://doi.org/10.1016/j.lwt.2022.113837

- Xu, J., Zhang, Y., Wang, W., Li, Y. (2020). Advanced properties of gluten-free cookies, cakes, and crackers: A review. Trends in Food Science & Technology, 103, 200–213. doi: https://doi.org/10.1016/j.tifs.2020.07.017

- Arribas, C., Cabellos, B., Cuadrado, C., Guillamón, E., Pedrosa, M. M. (2019). The effect of extrusion on the bioactive compounds and antioxidant capacity of novel gluten-free expanded products based on carob fruit, pea and rice blends. Innovative Food Science & Emerging Technologies, 52, 100–107. doi: https://doi.org/10.1016/j.ifset.2018.12.003

- Kudinov, P. I., Schekoldina, T. V., Slizkaya, A. S. (2012). Current status and structure of vegetable protein world resources. Izvestiya vysshih uchebnyh zavedeniy. Pischevaya tekhnologiya, 5-6, 7–10.

- Omaraliyeva, A., Botbayeva, Z., Agedilova, M., Abilova, M., Zhanaidarova, A. (2021). Determining the optimal parameters of ultra-high-frequency treatment of chickpeas for the production of gluten-free flour. Eastern-European Journal of Enterprise Technologies, 5 (11 (113)), 51–60. doi: https://doi.org/10.15587/1729-4061.2021.241877

- SHalagina, YU. A. (2016). Izmenenie obema krupy pri SVCh obrabotke. Evraziyskiy Soyuz Uchenyh (ESU), 4 (25), 49–52. Available at: https://cyberleninka.ru/article/n/izmenenie-obema-krupy-pri-svch-obrabotke

- Ling, B., Cheng, T., Wang, S. (2019). Recent developments in applications of radio frequency heating for improving safety and quality of food grains and their products: A review. Critical Reviews in Food Science and Nutrition, 60 (15), 2622–2642. doi: https://doi.org/10.1080/10408398.2019.1651690

- Antipova, L. V., Anikeeva, N. V. (2003). Chastnye issledovaniya tekhnologii polucheniya nutovoy muki i ee harakteristiki. Sovremennye tekhnologii pererabotki zhivotnovodcheskogo syr'ya v obespechenii zdorovogo pitaniya: nauka, obrazovanie i proizvodstvo: materialy mezhdunar. nauch.-tekhn. konf. Voronezh, 153–156.

- Kazantseva, I. L. (2016). Nauchno-prakticheskoe obosnovanie i sovershenstvovanie tekhnologii kompleksnoy pererabotki zerna nuta s polucheniem ingredientov dlya sozdaniya produktov zdorovogo pitaniya. Saratov, 47.

- Belmer, S., Khavkin, A. (2011). Gluten intolerance and indications for gluten-free diet. Vrach, 5, 17–21. Available at: http://pharmaco.rusvrach.ru/ru/vrach-2011-05-04

- «Hleb-ubiytsa». O vrede glyutena. Available at: https://celiac-ukraine.com/stati-o-tseliakii/chleb-ubiytsa--o-vrede-gliutena

- Fillips, G. O., Vil'yams, P. A. (2006). Spravochnik po gidrokolloidam. Sankt-Peterburg: GIORD, 536.

- Ekspress-test dlya tekhnologov. Available at: http://izvestia64.ru/news/205900-ekspress-test-dlya-tehnologov.html

- Batsukova, N. L., Borushko, N. V., Novikov, P. G. (2011). Mikrobiologicheskiy kontrol' za kachestvom pischevyh produktov i sanitarnym rezhimom na pischevyh predpriyatiyah. Minsk: BGMU, 47.

- Minchenko, L. A., Andreenko, L. V., Spivak, M. E., Akimova, S. A. (2021). Microbiological analysis of flour when used in baking. Tekhnologii pischevoy i pererabatyvayuschey promyshlennosti APK – produkty zdorovogo pitaniya, 4, 86–88. doi: https://doi.org/10.24412/2311-6447-2021-4-85-88

- Dorosh, A. P., Gregirchak, N. N. (2015). Antagonistic properties of dough sour with directed cultivation and evaluation of microbiological characteristics of bread produced on its basis. Tekhnika i tekhnologiya pischevyh proizvodstv, 37 (2), 10–15.

- Horstmann, S., Lynch, K., Arendt, E. (2017). Starch Characteristics Linked to Gluten-Free Products. Foods, 6 (4), 29. doi: https://doi.org/10.3390/foods6040029

- Domina, O. (2020). Features of finding optimal solutions in network planning. EUREKA: Physics and Engineering, 6, 82–96. doi: https://doi.org/10.21303/2461-4262.2020.001471

- Vasenko, Y. (2011). Wear resistance of titanium doped simulation of iron on the data passive experiment. Technology Audit and Production Reserves, 2 (2 (2)), 3–8. doi: https://doi.org/10.15587/2312-8372.2011.4858

- Frolova, L. (2011). Identification provision of energy saving on the basis of audit process moulding machines shaking. Technology Audit and Production Reserves, 2 (2 (2)), 8–13. doi: https://doi.org/10.15587/2312-8372.2011.4859

- Domina, O. (2020). Selection of alternative solutions in the optimization problem of network diagrams of project implementation. Technology Audit and Production Reserves, 4 (4 (54)), 9–22. doi: https://doi.org/10.15587/2706-5448.2020.210848

- Akimov, O., Penzev, P., Marynenko, D., Saltykov, L. (2018). Identification of the behavior of properties of a cold-hardening glass-liquid mixture with propylene-carbonate different in dosing components. Technology Audit and Production Reserves, 2 (3 (46)), 4–9. doi: https://doi.org/10.15587/2312-8372.2019.169748

- Chibichik, O., Sil’chenko, K., Zemliachenko, D., Korchaka, I., Makarenko, D. (2017). Investigation of the response surface describing the mathematical model of the effects of the Al/Mg rate and temperature on the Al-Mg alloy castability. ScienceRise, 5 (2), 42–45. doi: https://doi.org/10.15587/2313-8416.2017.101923

- Demin, D. (2018). Investigation of structural cast iron hardness for castings of automobile industry on the basis of construction and analysis of regression equation in the factor space «carbon (C) - carbon equivalent (Ceq)». Technology Audit and Production Reserves, 3 (1 (41)), 29–36. doi: https://doi.org/10.15587/2312-8372.2018.109097

- Popov, S., Frolova, L., Rebrov, O., Naumenko, Y., Postupna, О., Zubko, V., Shvets, P. (2022). Increasing the mechanical properties of structural cast iron for machine-building parts by combined Mn – Al alloying. EUREKA: Physics and Engineering, 1, 118–130. doi: https://doi.org/10.21303/2461-4262.2022.002243

- Demin, D. (2017). Strength analysis of lamellar graphite cast iron in the «carbon (C) – carbon equivalent (Ceq)» factor space in the range of C = (3,425-3,563) % and Ceq = (4,214-4,372) %. Technology Audit and Production Reserves, 1 (1 (33)), 24–32. doi: https://doi.org/10.15587/2312-8372.2017.93178

- Shelepina, N. V., Guseynova, N. E. (2010). Ispol'zovanie razlichnyh strukturoobrazovateley v proizvodstva pischevyh produktov. Nauchnye zapiski OrelGIET, 2, 429–431.

- Demin, D. (2013). Adaptive modeling in the problem of searching for the optimal control of the thermal treatment of cast iron. Eastern-European Journal of Enterprise Technologies, 6 (4 (66)), 31–37. doi: https://doi.org/10.15587/1729-4061.2013.19453

- Domina, O. (2021). Solution of the compromise optimization problem of network graphics on the criteria of uniform personnel loading and distribution of funds. Technology Audit and Production Reserves, 1 (4 (57)), 14–21. doi: https://doi.org/10.15587/2706-5448.2021.225527

- Turabi, E., Sumnu, G., Sahin, S. (2008). Rheological properties and quality of rice cakes formulated with different gums and an emulsifier blend. Food Hydrocolloids, 22 (2), 305–312. doi: https://doi.org/10.1016/j.foodhyd.2006.11.016

- Makarenko, D. (2017). Investigation of the response surfaces describing the mathematical model of the influence of temperature and BeO content in the composite materials on the yield and ultimate strength. Technology Audit and Production Reserves, 3 (3 (35)), 13–17. doi: https://doi.org/10.15587/2312-8372.2017.104895

- Domina, O., Lunin, D., Barabash, O., Balynska, O., Paida, Y., Mikhailova, L., Niskhodovska, O. (2018). Algorithm for selecting the winning strategies in the processes of managing the state of the system “supplier – consumer” in the presence of aggressive competitor. Eastern-European Journal of Enterprise Technologies, 6 (3 (96)), 48–61. doi: https://doi.org/10.15587/1729-4061.2018.152793

- Demin, D. (2017). Synthesis of nomogram for the calculation of suboptimal chemical composition of the structural cast iron on the basis of the parametric description of the ultimate strength response surface. ScienceRise, 8, 36–45. doi: https://doi.org/10.15587/2313-8416.2017.109175

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Aigul Omaraliyeva, Zhanar Botbayeva, Mereke Agedilova, Meruyert Abilova, Ainur Nurtayeva, Shyryn Baishugulova

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.