Optimum abrasive wear resistance for epoxy composites reinforced with polyethylene (PET) waste using Taguchi design and neural network

DOI:

https://doi.org/10.15587/1729-4061.2023.272534Keywords:

epoxy composites, PET waste, abrasive wear, Taguchi, artificial neural networkAbstract

The current work presents a study of the tribological properties of composite materials designed based on polyethylene terephthalate (PET), which has an important role in the structures of machines, represented by tribological couplings made of composite polymers. The paper examined the effect of two factors, namely recycled waste heating time (HT) and weight percentage (wt. %), on the improvement of the abrasive wear resistance of micro-filler-reinforced epoxy composites.

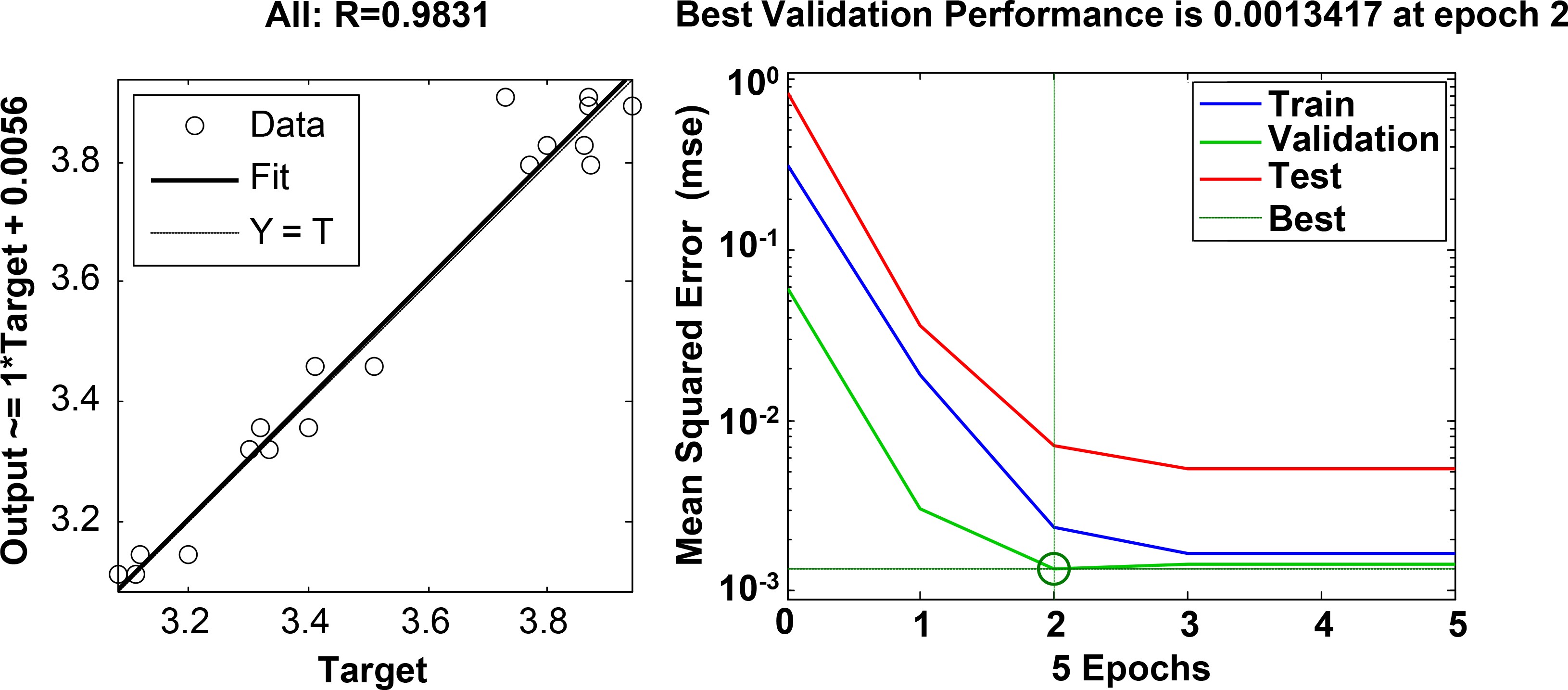

The current research aims to develop epoxy composites by improving abrasive wear resistance while ensuring low cost and weight. Improving wear resistance due to the use of epoxy composites to connect joints that operate under conditions without lubrication in various industrial fields will increase their operational life. The signal-to-noise ratio was analyzed to find out the effect of test parameters HT and wt. % on the wear rate of epoxy composites. Using MINITAB 19 software, regression equations were obtained for each variable to compare it with the Artificial Neural Network (ANN) results. Predictive models based on the regression equation and artificial neural network were developed to predict the wear rate of epoxy composites, and to determine which model is more efficient, their results were compared and the most appropriate model with the low error was determined. The results of the current research showed that the wear resistance of epoxy composites reinforced with RCCF improved by 41 % when increasing wt. % and HT, and also showed that the ANN model is more suitable than the regression model for predicting the wear rate of epoxy composites

References

- Dudin, V., Makarenko, D., Derkach, O., Muranov, Y. (2021). Determination of the influence of a filler on the properties of composite materials based on polytetrafluorothylene for tribosystems of mechanisms and machines. Eastern-European Journal of Enterprise Technologies, 4 (12 (112)), 61–70. doi: https://doi.org/10.15587/1729-4061.2021.238452

- Ray, S. (2021). Parametric Optimization and Prediction of Abrasion Wear Behavior of Marble-Particle-Filled Glass–Epoxy Composites Using Taguchi Design Integrated with Neural Network. JOM, 73 (7), 2050–2059. doi: https://doi.org/10.1007/s11837-021-04698-8

- Singh, A. K., Bedi, R., Kaith, B. S. (2020). Mechanical properties of composite materials based on waste plastic – A review. Materials Today: Proceedings, 26, 1293–1301. doi: https://doi.org/10.1016/j.matpr.2020.02.258

- Karabork, F. (2022). Investigation of the mechanical, tribological and corrosive properties of epoxy composite coatings reinforced with recycled waste tire products. Express Polymer Letters, 16 (11), 1114–1127. doi: https://doi.org/10.3144/expresspolymlett.2022.82

- Sivaras, R., Sathishkumar, T. P., Naveenathakrishnan, P. (2019). Investigation on Tribological and Mechanical Properties of Filler Reinforeced Epoxy Composite. International Journal of Engineering Research & Technology (IJERT), 7 (2). Available at: https://www.ijert.org/research/investigation-on-tribological-and-mechanical-properties-of-filler-reinforeced-epoxy-composite-IJERTCONV7IS02019.pdf

- Wojciechowski, Ł., Sydow, Z., Bula, K., Gapiński, B. (2023). Friction and wear of polypropylene-based composites reinforced with cherry seed powder. Tribology International, 179, 108177. doi: https://doi.org/10.1016/j.triboint.2022.108177

- Tian, J., Qi, X., Li, C., Xian, G. (2023). Friction behaviors and wear mechanisms of multi-filler reinforced epoxy composites under dry and wet conditions: Effects of loads, sliding speeds, temperatures, water lubrication. Tribology International, 179, 108148. doi: https://doi.org/10.1016/j.triboint.2022.108148

- Khalaf, A. A., Abed, S. A., Alkhfaji, S. S., Al-Obaidi, M. A., Hanon, M. M. (2022). The effect of adding natural materials waste on the mechanical properties and water absorption of epoxy composite using grey relations analysis. EUREKA: Physics and Engineering, 1, 131–142. doi: https://doi.org/10.21303/2461-4262.2022.001952

- Abed, S. A., Khalaf, A. A., Shaalan, T. G. (2020). Experiential Analysis of Mechanical Properties and Strain Energy of Epoxy/Micro Filler Cu-Ni Composite. Journal of Mechanical Engineering Research and Developments, 43(1), 143–150. Available at: https://jmerd.net/Paper/Vol.43,No.1(2020)/143-150.pdf

- Abed, S. A., Khalaf, A. A., Mnati, H. M., Hanon, M. M. (2022). Optimization of mechanical properties of recycled polyurethane waste microfiller epoxy composites using grey relational analysis and taguchi method. Eastern-European Journal of Enterprise Technologies, 1 (12 (115)), 48–58. doi: https://doi.org/10.15587/1729-4061.2022.252719

- Toth, L. F., Szebenyi, G., Sukumaran, J., De Baets, P. (2021). Tribological characterization of nanoparticle filled PTFE: Wear-induced crystallinity increase and filler accumulation. Express Polymer Letters, 15 (10), 972–986. doi: https://doi.org/10.3144/expresspolymlett.2021.78

- Imani, A., Zhang, H., Owais, M., Zhao, J., Chu, P., Yang, J., Zhang, Z. (2018). Wear and friction of epoxy based nanocomposites with silica nanoparticles and wax-containing microcapsules. Composites Part A: Applied Science and Manufacturing, 107, 607–615. doi: https://doi.org/10.1016/j.compositesa.2018.01.033

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Salwa A. Abed, Ahmad A. Khalaf, Muzher Taha Mohamed, Muammel M. Hanon

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.

A license agreement is a document in which the author warrants that he/she owns all copyright for the work (manuscript, article, etc.).

The authors, signing the License Agreement with TECHNOLOGY CENTER PC, have all rights to the further use of their work, provided that they link to our edition in which the work was published.

According to the terms of the License Agreement, the Publisher TECHNOLOGY CENTER PC does not take away your copyrights and receives permission from the authors to use and dissemination of the publication through the world's scientific resources (own electronic resources, scientometric databases, repositories, libraries, etc.).

In the absence of a signed License Agreement or in the absence of this agreement of identifiers allowing to identify the identity of the author, the editors have no right to work with the manuscript.

It is important to remember that there is another type of agreement between authors and publishers – when copyright is transferred from the authors to the publisher. In this case, the authors lose ownership of their work and may not use it in any way.