О ПУСКЕ В ЭКСПЛУАТАЦИЮ КРУПНОТОННАЖНОЙ ВРУ НА ОАО «МК «АЗОВСТАЛЬ»

DOI:

https://doi.org/10.18198/j.ind.gases.2008.0402Ключові слова:

Металлургия, Кислород, Азот, Аргон, Воздухоразделительная установка, Компрессор, Турбодетандер, Ректификация, Жидкие криопродукты, Ne-He-смесь, Kr-Xe-концентратАнотація

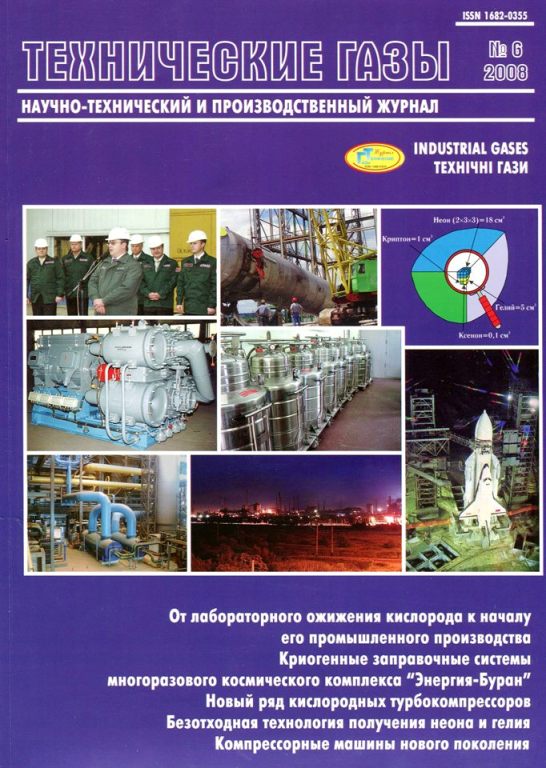

Комбинатом «Азовсталь» (г. Мариуполь, Украина), входящим в тройку лидеров отраслевого рейтинга металлургических предприятий Украины, ведётся целенаправленная работа по переоснащению, реконструкции и модернизации производства. Для обеспечения существующих и создаваемых на комбинате объектов кислородом и другими газами построена и введена в строй новая крупнотоннажная воздухоразделительная установка (ВРУ), изготовленная компанией «Air Liquide» (Франция). ВРУ-60 в основном режиме вырабатывает газообразный кислород: 20 тыс. м3/ч — низкого давления и 40 тыс. м3/ч — высокого давления. Она производит также газообразный и жидкий азот, жидкий аргон и газовые смеси редких газов Ne-He и Kr-Xe. В установке использованы современные схемы и конструкции, а также ряд оборудования, производимого ведущими зарубежными компаниями. Введённая в строй ВРУ-60 решит проблему надёжного обеспечения кислородом крупных потребителей доменного и конвертерного производств комбината.

##submission.downloads##

Номер

Розділ

Ліцензія

ЛІЦЕНЗІЙНИЙ ДОГОВІР

Після прийому статті до публікації редакція згідно з вимогами наукометричних баз кожному з авторів направляє ліцензійний договір про відступлення і передачу в управління авторських прав. Підпису автора (авторів) бажано скріпити печаткою відділу кадрів установи, в якій працює автор (автори), або печаткою факультету.

Редакція відсилає авторам одну верстку для коректури. Припустимі лише ті виправлення, які призводять верстку у відповідність з вихідним текстом статті. Внесення суттєвих змін не допускається. Верстку слід вислати до редакції протягом доби з моменту отримання.