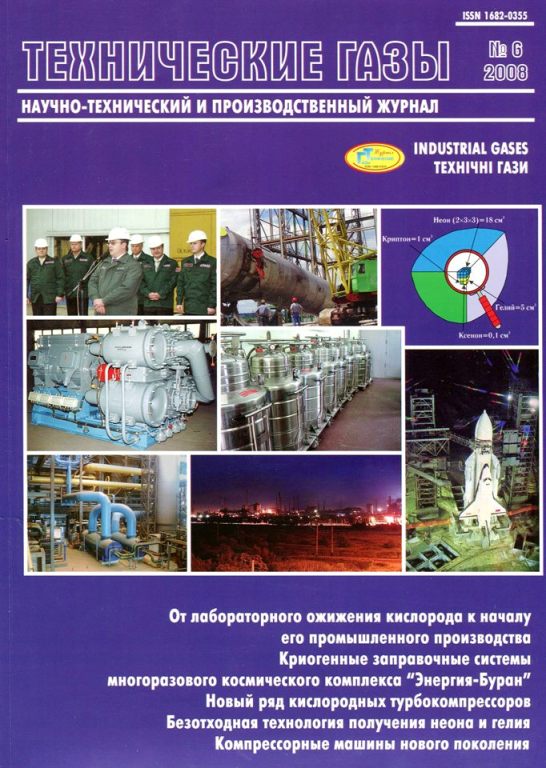

EXPERIENCE OF RECONSTRUCTION OF FILLING SHOP

DOI:

https://doi.org/10.18198/j.ind.gases.2008.0405Keywords:

Technical gases, Air separation products, Filling station, Reconstruction, Cryogenic tank, Cylinders, SafetyAbstract

Economic growth has caused increase of consumption of technical gases — oxygen, argon, nitrogen, and various gas mixtures which in turn determined the necessity of reconstruction of a gas filling plant at the Urals works of technical gases (Yekaterinburg, Russia). The aim was to make gas filling more efficient and safe and to improve the quality of cylinder gases. During modernization the number of loading platforms was increased from 2 to 14, new equipment was installed including cryogenic tanks and pumps, filling racks, forklifts, hydraulic trolleys etc. Herein the analysis of problems is given which Uraltechgaz engineers faced at different reconstruction stages such as design of facilities, choice of equipment, construction and assembling.

Downloads

Issue

Section

License

LICENSE AGREEMENT

After receiving an article for publication as required revision scientometric databases each author directs the license agreement on the assignment and transfer of the management of copyright. Signatures of the author (s) it is desirable to seal the personnel department of the institution where the author works (authors), or the seal of the Faculty.

Revision refers to the authors one layout for proofreading. Permissible only those fixes that result in compliance with the layout of the original text of the article. Significant changes are not permitted. Layout should be sent to the editorial office within days of receipt.