Аналіз різновидів глин та їх бінарних систем

DOI:

https://doi.org/10.15587/2706-5448.2022.266498Ключові слова:

хіміко-мінералогічний склад глин, кераміко-технологічні властивості, міцність кераміки, бінарні глинисті системиАнотація

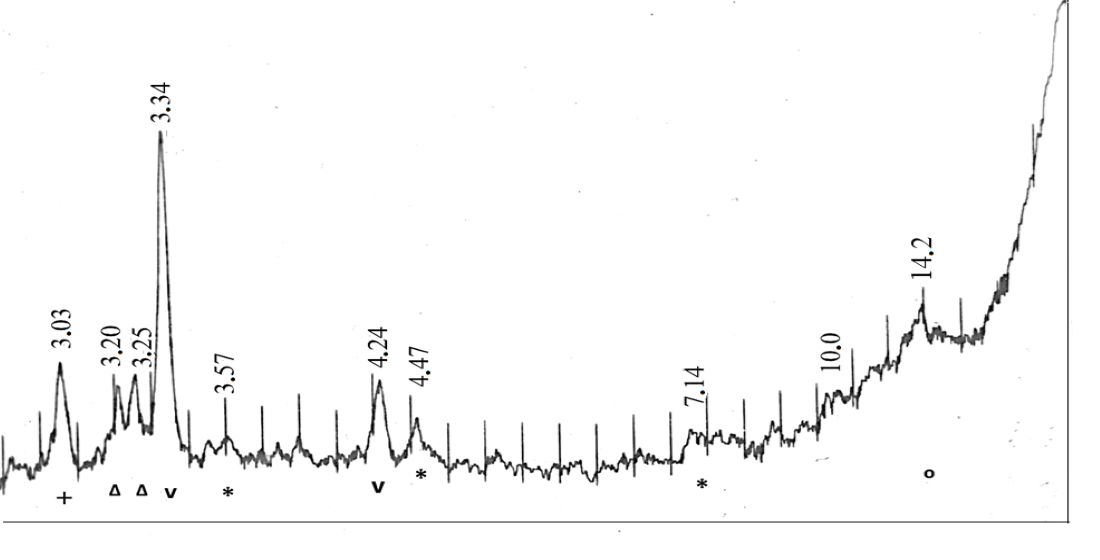

Об’єктами дослідження стали малобудищанська та опішнянська глини двох родовищ Полтавської області (Україна), бінарні системи цих глин і кераміка на їх основі. Відзначено, що ефективність практичного використання цих глин може бути підвищена при врахуванні особливостей їх мінералогічного складу. Методами хімічного, рентгенофазового та термічного аналізу досліджено особливості якісного мінералогічного складу глин. Визначено кількість породоутворюючих мінералів з використанням нової комп’ютерної програми «Мінерал». Встановлено, що при підвищеному вмісті кварцу в обох пробах малобудищанська глина характеризується сукупністю глинистих породоутворюючих мінералів – 18,8 % монтморилоніту, 12,1 % каолініту, 17,9 % польового шпату та 7 % кальциту. Опішнянська глина за інтенсивністю характерних дифракційних піків і площиною ендотермічного ефекту з максимумом при 550–575 °С відзначається значно більшим вмістом каолініту – 48,1 %. Більші значення кількісного співвідношення оксидів SiO2:Al2O3 та вмісту лужноземельних і лужних оксидів типу RO+R2O обумовлюють відношення малобудищанської глини до групи легкоплавких при вогнетривкості 1230 °С на відміну від вогнетривкої (1620 °С) опішнянської глини. Встановлено, що в інтервалі максимальних температур випалу 950–1100 °С зразки малобудищанської глини відрізняються від опішнянської змінами середньої густини з 1,90 до 2,28 г/см3 проти 2,00–2,09 г/см3, зменшенням водопоглинання з 15,3 до 5,0 мас.% проти 12,0–9,1 мас.%. Показано, що застосування бінарних систем досліджуваних глин суттєво впливає на хіміко-мінералогічнй склад, ступінь спікання та фізико-механічні показники кераміки. При варіюванні кількісного співвідношення глин від 4:1 до 1:1 найбільше змінюється вміст каолініту – від 19,3 до 30,1 %. Збільшення вмісту каолініту у бінарних системах призводить до поступового розширення можливого температурного інтервалу випалу. При цьому у порівнянні з малобудищанською глиною в опішнянській досягається зменшення водопоглинання, збільшення густини та міцності.

Посилання

- Worrall, W. E. (1982). Ceramic Raw Materials. Elsevier Science & Technology Books, 111.

- Richerson, D. W., Lee, W. E. (2018). Modern Ceramic Engineering. Properties, Processing, and Use in Design. CRC Press, 836. doi: https://doi.org/10.1201/9780429488245

- Fiori, C., Fabbri, B., Donati, G., Venturi, I. (1989). Mineralogical composition of the clay bodies used in the Italian tile industry. Applied Clay Science, 4 (5-6), 461–473. doi: https://doi.org/10.1016/0169-1317(89)90023-9

- Galos, K. (2011). Composition and ceramic properties of ball clays for porcelain stoneware tiles manufacture in Poland. Applied Clay Science, 51 (1-2), 74–85. doi: https://doi.org/10.1016/j.clay.2010.11.004

- Dietrich, W. F. (2018). The Clay Resources and the Ceramic Industry of California (Classic Reprint) Paperback. Forgotten Books, 420.

- Cherniak, L. P. (2003). Kryterii vyboru syrovyny dlia suchasnoho vyrobnytstva budivelnoi keramiky. Stroytelnie materyali y yzdelyia, 1 (2-4 (2)), 6–8.

- Varshavets, P. H., Sviderskyi, V. A., Cherniak, L. P. (2016). Keramichna tsehla z modyfikovanoiu poverkhneiu. Kyiv: Znannia, 182.

- Hossain, F. (2020). The Fundamentals of Brick Manufacturing. Nova Science Publishers, Incorporated, 147.

- John, D. (2021). Brickmaking: History and Heritage. Amberley Publishing Limited, 96.

- Rahaman, M. N. (2017). Ceramic Processing. CRC Press, 550. doi: https://doi.org/10.1201/9781315276045

- Nichiporenko, S. P., Abramovich, M. D., Komskaia, M. S. (1971). O formovanii keramicheskikh mass v lentochnykh pressakh. Kyiv: Naukova dumka, 75.

- Bykhova, A. F., Nichiporenko, S. P., Khilko, V. V. (1980). O vybore tekhnologii proizvodstva keramicheskikh mass. Kyiv: Naukova dumka, 50.

- Uorrel, U. (1978). Gliny i keramicheskoe syre. Mir, 237.

- Cherniak, L. P., Gontmakher, V. E. (1980). Mineralogicheskii sostav i spekanie glinistykh sistem. Steklo i keramika, 5, 22–23.

- Burst, J. F. (1991). The application of clay minerals in ceramics. Applied Clay Science, 5 (5-6), 421–443. doi: https://doi.org/10.1016/0169-1317(91)90016-3

- Sen, T. K. (2017). Clay Minerals: Properties, Occurrence, and Uses. Nova Science Publishers, 277.

- Aghayev, T., Küçükuysal, C. (2018). Ceramic properties of Uşak clay in comparison with Ukrainian clay. Clay Minerals, 53 (4), 549–562. doi: https://doi.org/10.1180/clm.2018.40

- Kagonbé, B. P., Tsozué, D., Nzeukou, A. N., Ngos, S. (2021). Mineralogical, physico-chemical and ceramic properties of clay materials from Sekandé and Gashiga (North, Cameroon) and their suitability in earthenware production. Heliyon, 7 (7), e07608. doi: https://doi.org/10.1016/j.heliyon.2021.e07608

- Brahina, L. L., Korohodska, A. M., Pitak, O. Ya. et. al.; Ryshchenka, M. I. (Ed.) (2012). Khimichna tekhnolohiia tuhoplavkykh nemetalevykh i sylikatnykh materialiv u prykladakh i zadachakh. Kharkiv: Pidruchnyk NTU «KhPY», 332.

- Studeniak, Ya. I., Voronych, O. H., Sukhareva, O. Yu., Fershal, M. V., Bazel, Ya. R. (2014). Praktykum z analitychnoi khimii. Instrumentalni metody analizu. Uzhhorod, 129.

- Ribeiro, A. C. F., Santos, C. I. A. V., Zaikov, G. E. (2016). Chemical Analysis: Modern Materials Evaluation and Testing Methods. CRC Press, 302. doi: https://doi.org/10.1201/b21419

- GOST 21216.0-93–GOST 21216.12-93. Syre glinistoe. Metody analiza. Vzamen GOST 21216.0-81–GOST 21216.12-81; Vved. 01.01.98 (1997). Kyiv: Gosstandart Ukrainy, 71.

- ASTM C67 Testing of Brick and Structural Clay Tile. Available at: https://www.testresources.net/applications/standards/astm/astm-c67-testing-of-brick-and-structural-clay-tile/

- Chernyak, L., Soroka, A. (2020). To The Question Of Determination Of Raw Materials Mineralogical Composition. Journal of Multidisciplinary Engineering Science and Technology, 7 (6), 12027–12031.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2022 Lev Chernyak, Valery Salnik, Nataliia Dorogan

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.