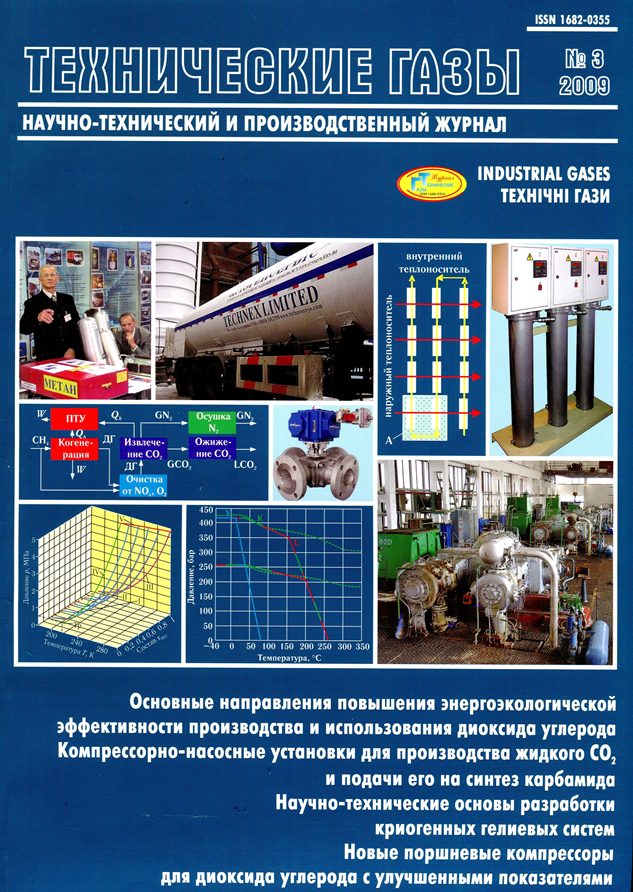

INCREASE OF ENERGOTECHNOLOGICAL EFFICIENCY OF MANUFACTURING AND USING OF CARBON DIOXIDE

DOI:

https://doi.org/10.18198/j.ind.gases.2009.0430Keywords:

Carbon dioxide, Carbon dioxide plant, Absorbent, Monoethanolamine, Methyldiethanolamine, Natural gas, Carbon dioxide compressor, Cycle of average pressure, Cycle of high pressure, Economy of natural gas, Electric power, Heat, Recycling of heat, AbsorptionAbstract

Perfection of carbon dioxide plants is directly connected with increase of efficiency of processes used in them, methods and circuits. Two types of carbon dioxide stations using natural gas are considered: with traditional technological construction; with new circuits in which processes of cogeneration and three-generation are applied. Directions of decrease of power expenses in plants of traditional type are proved. On their basis is possible to spend modernization and reconstruction of existing carbon dioxide stations. It is shown that at use of combustion gas from an extraneous source, for example, boiler plant, carbon dioxide station for manufacture of former quantity of low-temperature liquid carbon dioxide will spend, at least, on 30 % less than natural gas. Including of cogeneration plant in structure of carbon dioxide stations will allow to make simultaneously liquid carbon dioxide, electric power and heat. Recycling of thermal streams in such carbon dioxide stations can realise in steam-turbine station, enables to generate up to 40 % of additional electric power. Removal of oxygen from combustion gases, full dewatering and clearing of waste stream from an absorber allows to receive pure gaseous nitrogen as an additional product. Exergic efficiency of offered energotechnological complex reaches 40 %, i.e. in 10 times exceeds its value for traditional carbon dioxide station.

Downloads

Issue

Section

License

LICENSE AGREEMENT

After receiving an article for publication as required revision scientometric databases each author directs the license agreement on the assignment and transfer of the management of copyright. Signatures of the author (s) it is desirable to seal the personnel department of the institution where the author works (authors), or the seal of the Faculty.

Revision refers to the authors one layout for proofreading. Permissible only those fixes that result in compliance with the layout of the original text of the article. Significant changes are not permitted. Layout should be sent to the editorial office within days of receipt.