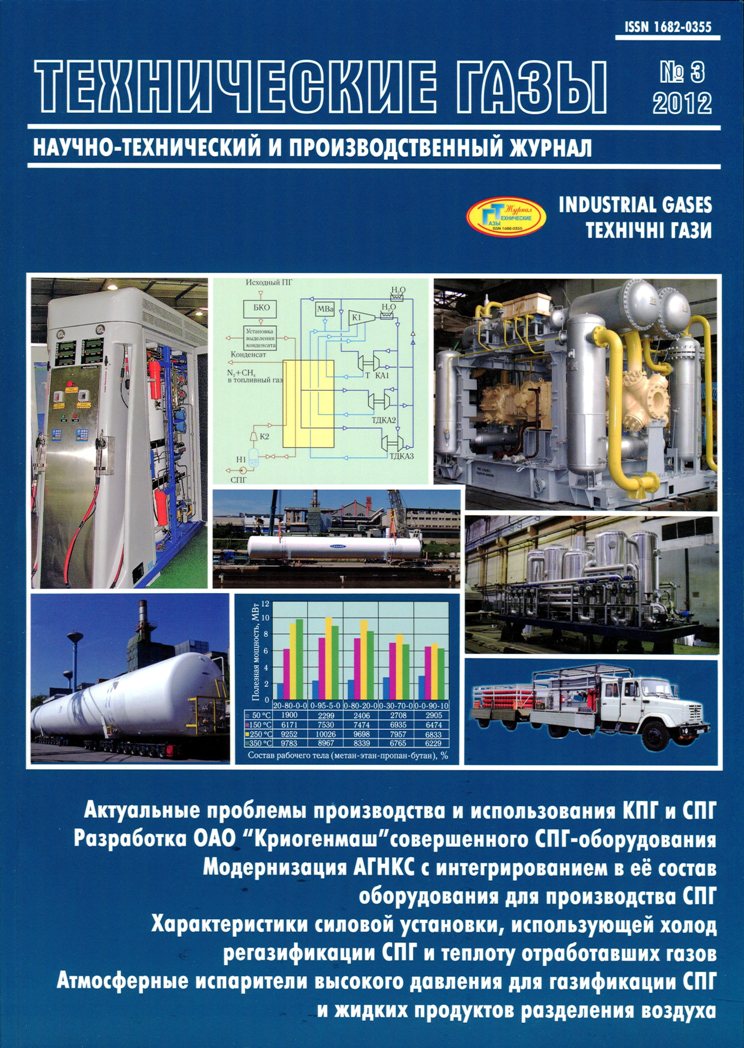

SCIENTIFIC AND ENGINEERING BASE, DEVELOPMENT AND PRODUCTION EXPERIENCE OF «CRYOGENMASH» — IMPROVEMENT LNG-EQUIPMENТ

DOI:

https://doi.org/10.18198/j.ind.gases.2012.0612Keywords:

Liquefied natural gas (LNG), High-pressure refrigeration cycle, Throttle-ejector stage, Specific energy consumption for LNG production, Expander nitrogen cycle, Expander stage, Turbo expander, Heat exchanger, Q-T-diagram, Losses of heat transfer irreverAbstract

Efficient and reliable LNG-installations are manufactured by company «Cryogenmash» — leader of Russian cryogenic engineering. In the small productivity installations is used a simple refrigeration cycle of high pressure liquefied natural gas. In them external cooling are carried out and ejectors are used instead of throttle. For more than ten of such LNG-installations to obtain 1,5; 2,5 and 3 t/h of product by company was supplied to China. The specific consumption of energy in them — 0,616 ... 0,753 kWh/kg of LNG. At the LNG installations of average production capacity the company intends to use for natural gas liquefaction the effective external nitrogen cooling cycles with several turbo-expander-compressor units. The сompany has developed LNG installations of average capacity to obtain from 7 to 100 t/h of LNG. The specific consumption of the energy in them is expected to be 0,45 - 0,49 kWh/kg of LNG. The company manufactures efficient cryogenic equipment for distribution infrastructure and using LNG. These include the LNG storage reservoirs with capacity from 5 to 250 m3, semitrailer — a cistern with capacity of 30 m3 of LNG. The company has enough scientific and engineering and manufacturing base for production of modern cryogenic equipment intended for implementation it in the different LNG technologies.

Downloads

Issue

Section

License

LICENSE AGREEMENT

After receiving an article for publication as required revision scientometric databases each author directs the license agreement on the assignment and transfer of the management of copyright. Signatures of the author (s) it is desirable to seal the personnel department of the institution where the author works (authors), or the seal of the Faculty.

Revision refers to the authors one layout for proofreading. Permissible only those fixes that result in compliance with the layout of the original text of the article. Significant changes are not permitted. Layout should be sent to the editorial office within days of receipt.