Analysis of clay types and their binary systems

DOI:

https://doi.org/10.15587/2706-5448.2022.266498Keywords:

chemical-mineralogical composition of clays, ceramic-technological properties, strength of ceramics, binary clay systemsAbstract

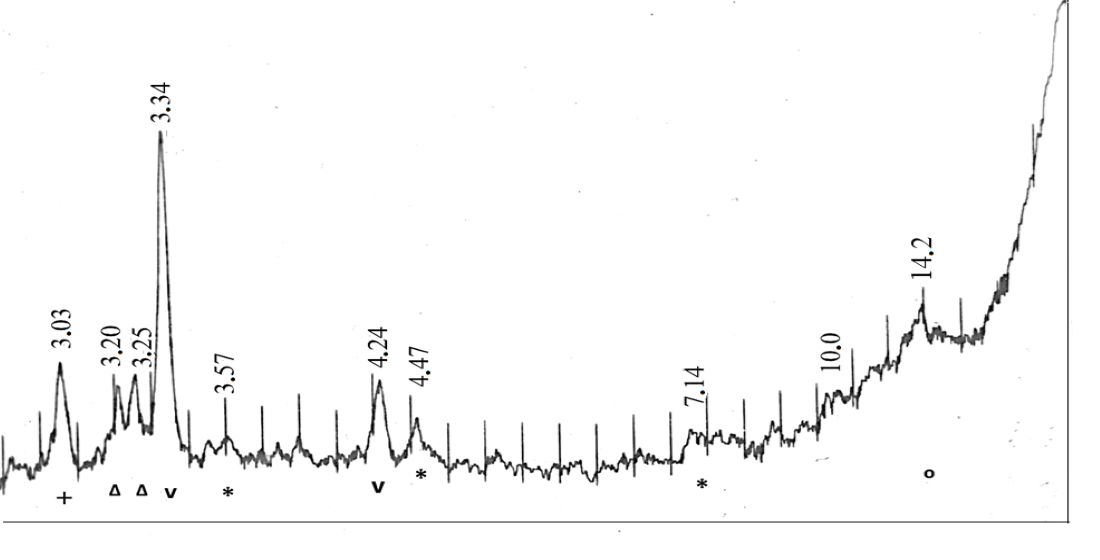

The objects of study were the Mali Budyshcha and Opishnia clays of two deposits in the Poltava region (Ukraine), binary systems of these clays, and ceramics based on them. It is noted that the efficiency of the practical use of these clays can be increased taking into account the peculiarities of their mineralogical composition. The features of the qualitative mineralogical composition of clays were studied by the methods of chemical, X-ray phase and thermal analysis. The amount of rock-forming minerals was determined using the new computer program «Mineral». It has been established that with an increased content of quartz in both samples, the Mali Budyshcha clay is characterized by a combination of clayey rock-forming minerals – 18.8 % montmorillonite, 12.1 % kaolinite, 17.9 % feldspar and 7 % calcite. According to the intensity of characteristic diffraction peaks and the plane of the endothermic effect with a maximum at 550–575 °C, Opishnia clay is marked by a significantly higher content of kaolinite – 48.1 %. Large values of the quantitative ratio of oxides SiO2:Al2O3 and the content of alkaline earth and alkaline oxides of the RO+R2O type determine the ratio of Mali Budyshcha clay to the group of low-melting clays with a fire resistance of 1230 °C, in contrast to refractory clay (1620 °C). It has been established that in the range of maximum firing temperatures of 950–1100 °C, samples of Mali Budyshcha clay differ from Opishnia clay in changes in average density from 1.90 to 2.28 g/cm3 versus 2.00–2.09 g/cm3, a decrease in water absorption from 15.3 to 5.0 wt % versus 12.0–9.1 wt %. It is shown that the use of binary systems of the studied clays has a significant effect on the chemical and mineralogical composition, the degree of sintering, and the physical and mechanical properties of ceramics. When varying the quantitative ratio of clays from 4:1 to 1:1, the content of kaolinite changes the most – from 19.3 to 30.1 %. An increase in the content of kaolinite in binary systems leads to a gradual expansion of the possible temperature range of firing. At the same time, in comparison with Mali Budyshcha clay, Opishnia clay achieves a decrease in water absorption, an increase in density and strength.

References

- Worrall, W. E. (1982). Ceramic Raw Materials. Elsevier Science & Technology Books, 111.

- Richerson, D. W., Lee, W. E. (2018). Modern Ceramic Engineering. Properties, Processing, and Use in Design. CRC Press, 836. doi: https://doi.org/10.1201/9780429488245

- Fiori, C., Fabbri, B., Donati, G., Venturi, I. (1989). Mineralogical composition of the clay bodies used in the Italian tile industry. Applied Clay Science, 4 (5-6), 461–473. doi: https://doi.org/10.1016/0169-1317(89)90023-9

- Galos, K. (2011). Composition and ceramic properties of ball clays for porcelain stoneware tiles manufacture in Poland. Applied Clay Science, 51 (1-2), 74–85. doi: https://doi.org/10.1016/j.clay.2010.11.004

- Dietrich, W. F. (2018). The Clay Resources and the Ceramic Industry of California (Classic Reprint) Paperback. Forgotten Books, 420.

- Cherniak, L. P. (2003). Kryterii vyboru syrovyny dlia suchasnoho vyrobnytstva budivelnoi keramiky. Stroytelnie materyali y yzdelyia, 1 (2-4 (2)), 6–8.

- Varshavets, P. H., Sviderskyi, V. A., Cherniak, L. P. (2016). Keramichna tsehla z modyfikovanoiu poverkhneiu. Kyiv: Znannia, 182.

- Hossain, F. (2020). The Fundamentals of Brick Manufacturing. Nova Science Publishers, Incorporated, 147.

- John, D. (2021). Brickmaking: History and Heritage. Amberley Publishing Limited, 96.

- Rahaman, M. N. (2017). Ceramic Processing. CRC Press, 550. doi: https://doi.org/10.1201/9781315276045

- Nichiporenko, S. P., Abramovich, M. D., Komskaia, M. S. (1971). O formovanii keramicheskikh mass v lentochnykh pressakh. Kyiv: Naukova dumka, 75.

- Bykhova, A. F., Nichiporenko, S. P., Khilko, V. V. (1980). O vybore tekhnologii proizvodstva keramicheskikh mass. Kyiv: Naukova dumka, 50.

- Uorrel, U. (1978). Gliny i keramicheskoe syre. Mir, 237.

- Cherniak, L. P., Gontmakher, V. E. (1980). Mineralogicheskii sostav i spekanie glinistykh sistem. Steklo i keramika, 5, 22–23.

- Burst, J. F. (1991). The application of clay minerals in ceramics. Applied Clay Science, 5 (5-6), 421–443. doi: https://doi.org/10.1016/0169-1317(91)90016-3

- Sen, T. K. (2017). Clay Minerals: Properties, Occurrence, and Uses. Nova Science Publishers, 277.

- Aghayev, T., Küçükuysal, C. (2018). Ceramic properties of Uşak clay in comparison with Ukrainian clay. Clay Minerals, 53 (4), 549–562. doi: https://doi.org/10.1180/clm.2018.40

- Kagonbé, B. P., Tsozué, D., Nzeukou, A. N., Ngos, S. (2021). Mineralogical, physico-chemical and ceramic properties of clay materials from Sekandé and Gashiga (North, Cameroon) and their suitability in earthenware production. Heliyon, 7 (7), e07608. doi: https://doi.org/10.1016/j.heliyon.2021.e07608

- Brahina, L. L., Korohodska, A. M., Pitak, O. Ya. et. al.; Ryshchenka, M. I. (Ed.) (2012). Khimichna tekhnolohiia tuhoplavkykh nemetalevykh i sylikatnykh materialiv u prykladakh i zadachakh. Kharkiv: Pidruchnyk NTU «KhPY», 332.

- Studeniak, Ya. I., Voronych, O. H., Sukhareva, O. Yu., Fershal, M. V., Bazel, Ya. R. (2014). Praktykum z analitychnoi khimii. Instrumentalni metody analizu. Uzhhorod, 129.

- Ribeiro, A. C. F., Santos, C. I. A. V., Zaikov, G. E. (2016). Chemical Analysis: Modern Materials Evaluation and Testing Methods. CRC Press, 302. doi: https://doi.org/10.1201/b21419

- GOST 21216.0-93–GOST 21216.12-93. Syre glinistoe. Metody analiza. Vzamen GOST 21216.0-81–GOST 21216.12-81; Vved. 01.01.98 (1997). Kyiv: Gosstandart Ukrainy, 71.

- ASTM C67 Testing of Brick and Structural Clay Tile. Available at: https://www.testresources.net/applications/standards/astm/astm-c67-testing-of-brick-and-structural-clay-tile/

- Chernyak, L., Soroka, A. (2020). To The Question Of Determination Of Raw Materials Mineralogical Composition. Journal of Multidisciplinary Engineering Science and Technology, 7 (6), 12027–12031.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Lev Chernyak, Valery Salnik, Nataliia Dorogan

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.