Dependence of current conductivity of polyethylene-graphite compositions on the method of their manufacture

DOI:

https://doi.org/10.15587/2706-5448.2023.274763Keywords:

thermally expanded graphite, high-pressure linear polyethylene, powder technology, electrical resistance, flow thresholdAbstract

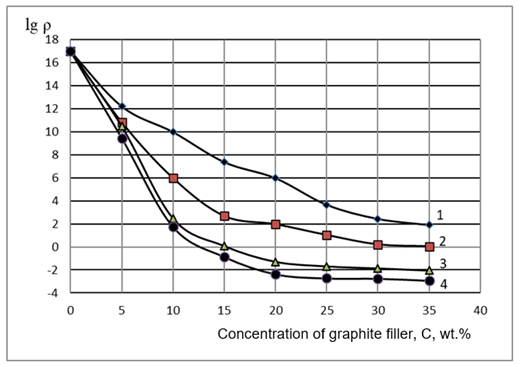

The paper presents the results of the study of the dependence of the properties of polymer composites of the linear high-pressure polyethylene (LHPPET) system – graphite fillers of various types: natural GAK-2, thermally expanded (TEG) and with ultrasonic treatment. The test samples contained a filler in a wide concentration range (5–35 wt. %). Samples were manufactured using rolling, pressing and powder technology methods. Electrical resistance was measured by the four-probe potentiometric method at constant current. It is shown that the electrical resistance decreases sharply in a narrow concentration interval of 5–15 wt. % from 6.77·1010 to 4.9·102 Ω·m (for compositions obtained by rolling), from 2.96·1010 to 1.2 Ω·m (for pressed samples), from 2.87·109 to 0.14 Ω·m (for compositions obtained by powder technology). For samples of the LHPPET – GAK-2 system, a rapid decrease in electrical resistance is observed at filler concentrations of 5–30 wt. % from 1.36·1012 Ω·m to 2.79·102 Ω·m. Using thermally expanded graphite with and without ultrasonic treatment (and to a lesser extent GAK-2) it is possible to obtain polymer composite materials (PCM) with volume resistivity ranging from 6.77 to 1.9·10-3 Ω·m. It has been experimentally confirmed that electrical conductivity largely depends on the PCM manufacturing technology. The established dependences of the current conductivity of composites, depending on the manufacturing method, are associated with the corresponding structural differences. These structural differences are manifested in an increase in the number and area of contacts of filler particles – graphite and in a change in the thickness of the layers of the polymer matrix. Dry powder technology is the most effective method of obtaining LHPPET – graphite compositions. The optimal composition of the composition is 25 wt. % TEG and 75 wt. % LHPPET. Directions of practical use of the obtained results can be effectively used in industry and housing and communal economy.

Supporting Agency

- Presentation of research in the form of publication through financial support in the form of a grant from SUES (Support to Ukrainian Editorial Staff).

References

- Suberliak, O. V., Bashtannyk, P. I. (2006). Tekhnolohiia pererobky polimernykh ta kompozytsiinykh materialiv. Kyiv, 270.

- Semko, L. S., Chernysh, I. H., Vovchenko, L. L., Matsui, L. Yu. (1991). Elektrofizychni vlastyvosti kompozytsiinykh materialiv na osnovi polietylenu ta termorozshyrenoho hrafitu. Plastychni masy, 8, 20–23.

- Melnyk, L. I. (2009). Zakonomirosti formuvannia i zastosuvannia termostiikykh strumoprovidnykh syloksanhrafitovykh materialiv. Kyiv, 178.

- Lozitsky, O. V., Vovchenko, L. L., Matzui, L. Y., Milovanov, Y. S., Garashchenko, V. V. (2021). Electrical properties of epoxy composites with carbon nanotubes, mixed with TiO2 or Fe particles. Applied Nanoscience, 11 (6), 1827–1837. doi: https://doi.org/10.1007/s13204-021-01838-z

- Vovchenko, L. L., Matzui, L. Y., Yakovenko, O. S., Lozitsky, O. V., Len, T. A., Oliynyk, V. V. et al. (2022). Electrical and shielding properties of epoxy composites with Ni–C and Co–C core-shell nanoparticles. Physica E: Low-Dimensional Systems and Nanostructures, 144, 115463. doi: https://doi.org/10.1016/j.physe.2022.115463

- Semko, L. S., Chernysh, I. H., Svyntsytskyi, N. I. (1994). Dynamichni ta mekhanichni vlastyvosti kompozytsiinykh materialiv na osnovi polietylenu ta termorozshyrenoho hrafitu. Problemy mitsnosti, 7, 84–91.

- Semko, L. S., Chernysh, I. H., Revo, L. S., Dashevskyi, N. M. (1992). Mekhanichni vlastyvosti kompozytsiinykh materialiv na osnovi polietylenu ta termorozshyrenoho hrafitu. Mekhanika kompozytnykh materialiv, 3, 307–314.

- Semko, L. S., Chernysh, I. H., Aleksieiev, O. M, Popov, R. Ye. (1990). Dielektrychni vlastyvosti PENT napovnenoho termorozshyrenym hrafitom. Plastychni masy, 2, 16–22.

- Mamunia, Ye. P. (2000). Elektrychna ta termichna providnist pomirnykh kompozytsii zdyspersnymy napovniuvachamy. Ukrainskyi khimichnyi zhurnal, 66 (3), 55–58.

- Chernysh, I. H. (1994). Pryrodnyi hrafit ta materialy na yoho osnovi. Khimichna promyslovist Ukrainy, 4, 4–8.

- Novykov, I. M., Chernysh, I. H. (1994). Suchasni tendentsii vyrobnytstva ta zastosuvannia vuhletsevo-hrafitovykh materialiv v Ukraini. Khimichna promyslovist Ukrainy, 4, 2–3.

- Melnyk, L. I., Volynets, R. P., Budia, D. O. (2010). Struktura i fizyko-khimichni vlastyvosti pryrodnykh ta termorozshyrenykh hrafitiv. Naukovi visti NTUU «KPI», 6, 141–146.

- Stelmakh, O. I., Matsui, L. Yu., Vovchenko, L. L. (2007). Electrical Resistivity of Composite Materials Based on Thermoexfoliated Graphite. Fizyka i khimiia tverdoho tila, 2, 408–413.

- Yu, Y., Song, S., Bu, Z., Gu, X., Song, G., Sun, L. (2013). Influence of filler waviness and aspect ratio on the percolation threshold of carbon nanomaterials reinforced polymer nanocomposites. Journal of Materials Science, 48 (17), 5727–5732. doi: https://doi.org/10.1007/s10853-013-7364-z

- Zhang, W., Dehghani-Sanij, A. A., Blackburn, R. S. (2007). Carbon based conductive polymer composites. Journal of Materials Science, 42 (10), 3408–3418. doi: https://doi.org/10.1007/s10853-007-1688-5

- Li, J., Ma, P. C., Sze, C. W., Kai, T. C., Tang, B. Z., Kim, J. K. (2007). Percolation threshold of polymer nanocomposites containing graphite nanoplatelets and carbon nanotubes. ICCM. Available at: http://repository.ust.hk/ir/Record/1783.1-50129

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Liubov Melnyk, Pavel Chulkin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.