Determination of the influence of the sound capillary effect on the process of soaking vegetable raw materials in the acoustic extractor

DOI:

https://doi.org/10.15587/2706-5448.2023.275236Keywords:

extraction of biologically active substances, plant raw materials, ultrasound, extractant, sound capillary effect, capillary, cavitationAbstract

The object of research is the process of liquid movement in capillaries during the extraction of biologically active substances (BAS) from plant raw materials under the action of the sound capillary effect. A characteristic feature of vegetable raw materials is a large number of pores of the capillary type. Penetration of the extractant into the raw material occurs through capillaries and leads to the filling of cells and voids in it. The process of filling the capillaries and cell voids with the extractant can be quite long and significantly increase the extraction time as a whole.

It was established that the penetration of the extractant into the capillaries of plant raw materials is affected by ultrasonic vibrations that cause cavitation. Under the action of cavitation, which occurs in the ultrasonic field, the penetration of the extractant into narrow cavities and crevices is accelerated and deepened. This phenomenon is called the sound capillary effect. The analysis of literary sources showed that there are no data on the study of the conditions for the occurrence of the sound capillary effect and the effect on the speed of movement of liquid in the capillaries of ultrasonic pressure during the BAS extraction from plant raw materials. Numerical modeling was used to study the movement of liquid (extractant) in capillaries during the BAS extraction from plant raw materials under the conditions of ultrasound.

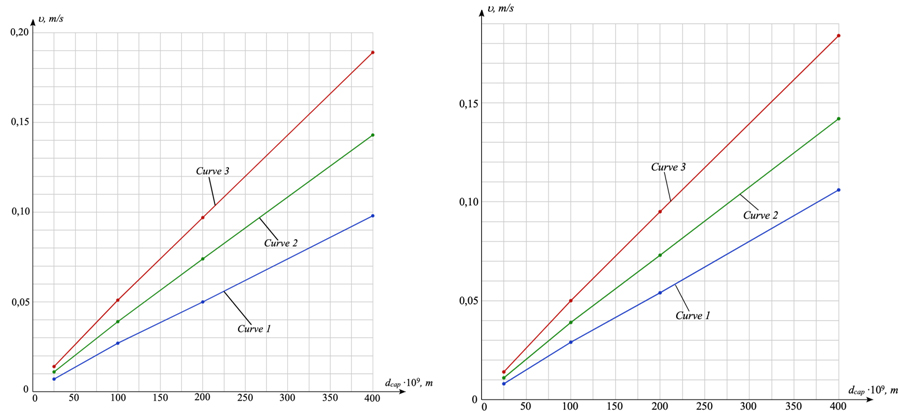

As a result of the conducted research, the conditions for the occurrence of ultrasonic cavitation in the process of BAS extraction from plant raw materials with the most common extractants, such as water and ethanol solutions, were found. The values of the amplitude of the sound pressure of the extractant, which occurs under the conditions of the sound capillary effect directly at the entrance to the capillary, were also found. The dependences of the sound capillary pressure on the diameter of the capillary for the most common extractants have been established. The influence of the sound-capillary effect on the speed of movement of the most common extractants in capillaries of different sizes is determined.

The obtained research results allow to quantitatively evaluate the influence of the sound-capillary effect on the movement of extractants in the capillaries of plant raw materials, on the rate of wetting of plant raw materials and the speed of mass exchange processes during extraction. These results can be used when choosing operating modes of existing and designing new equipment for the BAS extraction from plant raw materials under ultrasound conditions.

References

- Korobiichuk, I., Melnick, V., Ostapenko, Z., Ruzhinska, L. (2022). Investigation of heat and mass transfer processes in the extraction of vegetable raw materials under the conditions of ultrasound. 22nd SGEM International Multidisciplinary Scientific GeoConference Proceedings 2022, Energy and Clean Technologies. doi: https://doi.org/10.5593/sgem2022/4.1/s17.16

- Melnyk, V. M., Ruzhynska, L. I., Andruk, M. M. (2017). Ultrazvukova dezyntehratsiia roslynnoi syrovyny v tekhnolohii otrymannia karotynoidiv. Internauka, 18.

- Martínez-Patiño, J. C., Gullón, B., Romero, I., Ruiz, E., Brnčić, M., Žlabur, J. Š., Castro, E. (2019). Optimization of ultrasound-assisted extraction of biomass from olive trees using response surface methodology. Ultrasonics Sonochemistry, 51, 487–495. doi: https://doi.org/10.1016/j.ultsonch.2018.05.031

- Wen, C., Zhang, J., Zhang, H., Dzah, C. S., Zandile, M., Duan, Y., Ma, H., Luo, X. (2018). Advances in ultrasound assisted extraction of bioactive compounds from cash crops – A review. Ultrasonics Sonochemistry, 48, 538–549. doi: https://doi.org/10.1016/j.ultsonch.2018.07.018

- Toma, M., Vinatoru, M., Paniwnyk, L., Mason, T. J. (2001). Investigation of the effects of ultrasound on vegetal tissues during solvent extraction. Ultrasonics Sonochemistry, 8 (2), 137–142. doi: https://doi.org/10.1016/s1350-4177(00)00033-x

- Arabi, M., Ghaedi, M., Ostovan, A., Tashkhourian, J., Asadallahzadeh, H. (2016). Synthesis and application of molecularly imprinted nanoparticles combined ultrasonic assisted for highly selective solid phase extraction trace amount of celecoxib from human plasma samples using design expert (DXB) software. Ultrasonics Sonochemistry, 33, 67–76. doi: https://doi.org/10.1016/j.ultsonch.2016.04.022

- Yang, R.-F., Geng, L.-L., Lu, H.-Q., Fan, X.-D. (2017). Ultrasound-synergized electrostatic field extraction of total flavonoids from Hemerocallis citrina baroni. Ultrasonics Sonochemistry, 34, 571–579. doi: https://doi.org/10.1016/j.ultsonch.2016.06.037

- Chen, L., Jin, H., Ding, L., Zhang, H., Li, J., Qu, C., Zhang, H. (2008). Dynamic microwave-assisted extraction of flavonoids from Herba Epimedii. Separation and Purification Technology, 59 (1), 50–57. doi: https://doi.org/10.1016/j.seppur.2007.05.025

- Ponomarev, V. D. (1976). Ekstragirovanie rastitelnogo syria. Moscow: Meditcina, 204.

- Minina, S. A., Kaukhova, I. E. (2009). Khimiia i tekhnologiia fitopreparatov. Moscow: GEO-TAR-Media, 560.

- Dubashinskaia, N. V., Khishova, O. M. (2008). Opredelenie nabukhaniia i pogloshchaiushchei sposobnosti kornevishch s korniami siniukhi. Vestnik farmatcii, 1 (39).

- Rozina, E. Iu. (2003). Kavitatcionnyi rezhim zvukokapilliarnogo effekta. Akustichnii vіsnik, 6 (1), 48–59.

- Luhovskoi, A. F., Chukhraev, N. V. (2007). Ultrazvukovaia kavytatsyia v sovremennikh tekhnolohyiakh. Kyiv: Vydavnycho-polihrafichnyi tsentr – Kyivskyi universytet, 244.

- Luhovskyi, O. F., Movchaniuk, A. V., Bernyk, I. M., Shulha, A. V., Hryshko, I. A. (2021). Aparatne zabezpechennia ultrazvukovykh kavitatsiinykh tekhnolohii. Kyiv: KPI im. Ihoria Sikorskoho. Vydavets FOP Kushnir Yu.V., 216.

- Rozina, E. Iu. (2003). O prirode sily, deistvuiushchei na kavitiruiushchuiu sredu u sreza kapilliara. Akustichnii vіsnik, 6 (3), 60–68.

- Bronin, F. A. (1967). Issledovanie kavitatcionnogo razrusheniia i dispergirovaniia tverdykh tel v ultrazvukovom pole vysokoi intensivnosti. Moscow, 299.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Zhanna Ostapenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.