Adjustment of the axial load on the bit when hole deepening by using the screw mechanism

DOI:

https://doi.org/10.15587/2706-5448.2023.275242Keywords:

screw mechanism, axial load, ball bit, adjustment, drill string, hole deepeningAbstract

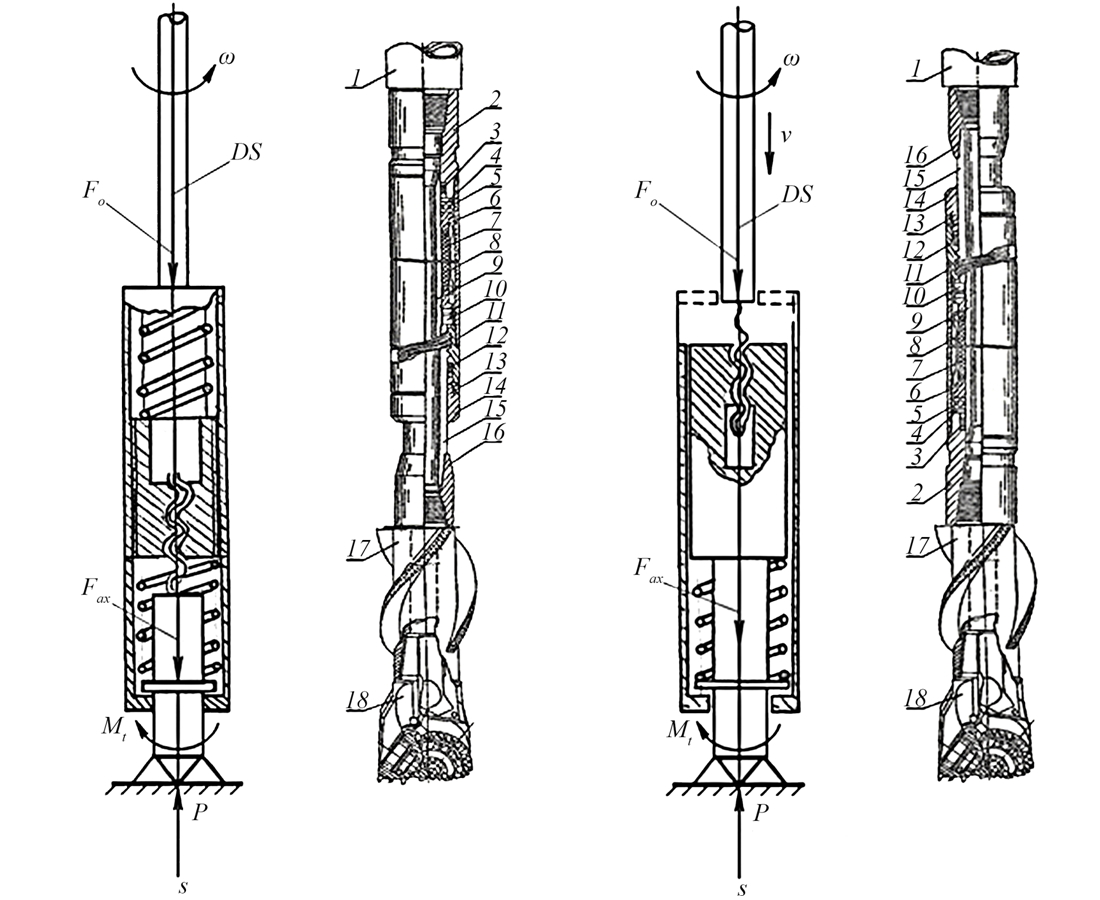

The object of the research is a screw mechanism for adjusting the axial load on the bit during a hole deepening.

Mathematical modeling of dynamic processes that occur in the drill string during the hole deepening in deep wells is considered. It is shown that in the process of hole deepening, the longitudinal oscillations are proportional in their intensity to the torsional ones. Obtained boundary conditions for mathematical models of the column with the use of a shock absorber or a screw amplifier.

In the course of research, it was found that the screw working mechanism of the axial load creates a relationship between the axial load on the bit and the torque on the screw. This makes it possible to install safety devices that limit the torque of the drive shaft (reciprocating engine, rotor). It is shown that various types of energy supplied to the punch, which are transformed by the punching motor and amplified due to the axial (screw) amplifier installed above the bit, ensure the rotary-progressive movement of the ball bit and increase the drilling performance. It was determined that the obtained dependencies take into account the change in time of the axial load and torque depending on the parameters of the axial amplifier and the geological and technical conditions of drilling and the arrangement of the bottom of the drill string.

The research results will be useful to scientists and specialists of the oil and gas industry during the physical modeling of the processes of adjusting the axial load on the bit during a hole deepening by using a screw mechanism.

References

- Iunin, E. K. (1983). Upravlenie nizkochastotnimi kolebaniiami burilnoi kolonni s tceliu povisheniia effektivnosti protcessa bureniia. Moscow, 367.

- Riane, R., Doghmane, M. Z., Kidouche, M., Tee, K. F., Djezzar, S. (2022). Stick-Slip Vibration Suppression in Drill String Using Observer-Based LQG Controller. Sensors, 22 (16), 5979. doi: https://doi.org/10.3390/s22165979

- Vaziri, V., Kapitaniak, M., Wiercigroch, M. (2018). Suppression of drill-string stick–slip vibration by sliding mode control: Numerical and experimental studies. European Journal of Applied Mathematics, 29 (5), 805–825. doi: https://doi.org/10.1017/s0956792518000232

- Surnin, L. S. (1986). Prvishenie effektivnosti primeneniia amortizatorov na baze issledovaniia volnovikh protcessov v burilnoi kolonne. Ivano-Frankovsk, 187.

- Ullah, F. K., Duarte, F., Bohn, C. (2016). A Novel Backstepping Approach for the Attenuation of Torsional Oscillations in Drill Strings. Solid State Phenomena, 248, 85–92. doi: https://doi.org/10.4028/www.scientific.net/ssp.248.85

- Ogorodnikov, P. I. (1990). Upravlenie upravleniia zaboia skvazhini na baze izucheniia dinamicheskikh protcessov v burilnoi kolonne. Moscow, 423.

- Tcifanskii, S. L., Beresnevich, V. I., Oks, A. B. (1991). Nelineinye i parametricheskie kolebaniia vibratcionnykh mashin tekhnologicheskogo naznacheniia. Riga: Zinatne, 229.

- Canudas-de-Wit, C., Rubio, F. R., Corchero, M. A. (2008). D-OSKIL: A New Mechanism for Controlling Stick-Slip Oscillations in Oil Well Drillstrings. IEEE Transactions on Control Systems Technology, 16 (6), 1177–1191. doi: https://doi.org/10.1109/tcst.2008.917873

- Shelepin, E. I., Ogorodnikov, P. I., Surnin, L. S. et al. (1969). A.s. SRSR No. 287858 Amortizator kolebanii burilnoi kolonni. MKI E2V17/06. Declareted: 29.09.69, published: 03.12.69, Bul. No. 36.

- Tishchenko, O. F., Kiselev, L. T., Kovalenko, A. P. et al. (1982). Elementy pribornykh ustroistv. Ch. 1. Detali, soedineniia i peredachi. Moscow: Vysshaia shkola, 304.

- Kolchin, I. I. (1972). Mekhanika mashin. Vol. 2. Moscow: Mashinostroenie, 454.

- Bocharov, Iu. A. (1976). Vintovye pressy. Moscow: Mashinostroenie, 245.

- Allikvander, E. A. (1969). Sovremennoe glubokoe burenie. Moscow: Nedra, 228.

- Grigorian, N. A., Bagirov, R. E. (1982). Analiz protcessa turbinnogo bureniia. Moscow: Nedra, 206.

- Mikhaltcev, V., Moliakov, V. (2020). Teoriia i proektirovanie gazovoi turbiny. Moscow: MGTU im. N. E. Baumana, 230.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Viktor Svitlytskyi, Tetiana Sahala

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.