Technology of protein isolate from peas (Pisum sativum var. arvense)

DOI:

https://doi.org/10.15587/2706-5448.2023.278118Keywords:

pea seeds, vegetables, protein isolate, pH-shifting treatment, sausage products, quality characteristicsAbstract

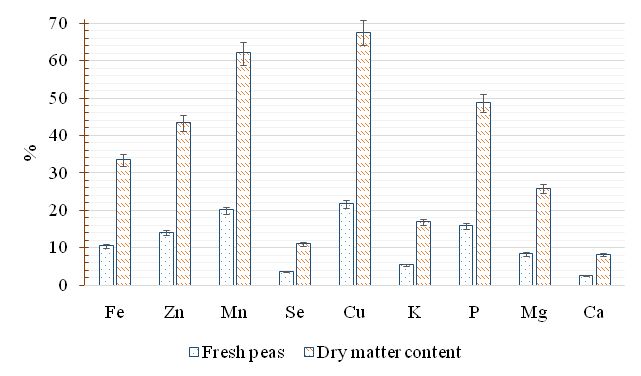

The object of research is pea (Pisum sativum var. arvense) and pea protein isolate. The chemical composition of pea (Pisum sativum var. arvense) was studied to determine its potential as a new raw material for obtaining protein isolate by pH-shifting treatment. The obtained results confirm the effectiveness of using peas to obtain protein isolate for use in the food industry instead of soy protein isolate. Peas are low in lipids (1.61 % on dry matter), high in crude protein (19.21 % on dry matter), ash (3.41 % on dry matter) and minerals (Se, Fe, Zn, Mn, Cu, Mg, P). The ratio of essential amino acids to replaceable amino acids (0.78), which is higher than the amount recommended by the World Health Organization. Vegetable protein is an alternative to animal protein in the food industry. Protein isolate from peas was obtained by pH-shifting treatment and its chemical composition and functional properties were determined. After pH-shifting treatment, the chemical composition of protein and mineral substances did not show significant changes. The protein content of pea protein isolate was 82.2 %, and the yield of pea protein isolate was 5.6 %. To confirm the functional properties of pea protein isolate, the indicators of moisture-holding capacity (1.05 ml/g) and fat-holding capacity (0.82 ml/g) were investigated. Peas and protein isolate from it showed high functional properties and high-quality chemical composition of proteins and minerals for use in the technology of sausage products, which should be the focus of further research.

References

- Nikbakht Nasrabadi, M., Sedaghat Doost, A., Mezzenga, R. (2021). Modification approaches of plant-based proteins to improve their techno-functionality and use in food products. Food Hydrocolloids, 118, 106789. doi: https://doi.org/10.1016/j.foodhyd.2021.106789

- Kumar, M., Tomar, M., Potkule, J., Reetu, Punia, S., Dhakane-Lad, J. et al. (2022). Functional characterization of plant-based protein to determine its quality for food applications. Food Hydrocolloids, 123, 106986. doi: https://doi.org/10.1016/j.foodhyd.2021.106986

- Tiwari, B. K., Gowen, A., McKenna, B.; Tiwari, B. K., Gowen, A., McKenna, B. (Eds.) (2011). Introduction. Pulse foods processing, quality and nutraceutical applications. London: Academic Press Elsevier, 1–7. doi: https://doi.org/10.1016/b978-0-12-382018-1.00001-0

- Gao, D., Helikh, A., Duan, Z. (2021). Functional properties of four kinds of oilseed protein isolates. Journal of Chemistry and Technologies, 29 (1), 155–163. doi: https://doi.org/10.15421/082116

- Boye, J. I., Aksay, S., Roufik, S., Ribéreau, S., Mondor, M., Farnworth, E., Rajamohamed, S. H. (2010). Comparison of the functional properties of pea, chickpea and lentil protein concentrates processed using ultrafiltration and isoelectric precipitation techniques. Food Research International, 43 (2), 537–546. doi: https://doi.org/10.1016/j.foodres.2009.07.021

- Toews, R., Wang, N. (2013). Physicochemical and functional properties of protein concentrates from pulses. Food Research International, 52 (2), 445–451. doi: https://doi.org/10.1016/j.foodres.2012.12.009

- Adebiyi, A. P., Aluko, R. E. (2011). Functional properties of protein fractions obtained from commercial yellow field pea (Pisum sativum L.) seed protein isolate. Food Chemistry, 128 (4), 902–908. doi: https://doi.org/10.1016/j.foodchem.2011.03.116

- Helikh, A. О., Gao, D., Duan, Z. (2020). Optimization of ultrasound-assisted alkaline extraction of pumpkin seed meal protein isolate by response surface methodology. Scientific Notes of Taurida National V.I. Vernadsky University. Series: Technical Sciences, 2 (2), 100–104. doi: https://doi.org/10.32838/2663-5941/2020.2-2/17

- Helikh, A., Danylenko, S., Kryzhska, T., Semernia, O. (2022). Optimization of rheological indicators of yoghurt structure with addition of hemp seed protein isolate. Food resources, 10 (18), 51–60. doi: https://doi.org/10.31073/foodresources2022-18-05

- Tiwari, B. K., Singh, N. (2012). Pulse chemistry and technology. Cambridge: Royal Society of Chemistry. doi: https://doi.org/10.1039/9781839169038

- Shand, P. J., Ya, H., Pietrasik, Z., Wanasundara, P. K. J. P. D. (2007). Physicochemical and textural properties of heat-induced pea protein isolate gels. Food Chemistry, 102 (4), 1119–1130. doi: https://doi.org/10.1016/j.foodchem.2006.06.060

- Shevkani, K., Singh, N., Rana, J. C., Kaur, A. (2013). Relationship between physicochemical and functional properties of amaranth (Amaranthus hypochondriacus) protein isolates. International Journal of Food Science & Technology, 49 (2), 541–550. doi: https://doi.org/10.1111/ijfs.12335

- Sathe, S. K. (2002). Dry Bean Protein Functionality. Critical Reviews in Biotechnology, 22 (2), 175–223. doi: https://doi.org/10.1080/07388550290789487

- Helikh, A., Danylenko, S., Kryzhska, T., Qingshan, L. (2021). Development of technology and research of quality indicators of yoghurt with natural filler in the preservation process. Food Resources, 9 (16), 69–78. doi: https://doi.org/10.31073/foodresources2021-16-07

- Helikh, A., Samilyk, M., Prymenko, V., Vasylenko, O. (2020). Modeling of Craft Technology of Boiled Sausage «Firm Plus». Restaurant and Hotel Consulting. Innovations, 3 (2), 237–251. doi: https://doi.org/10.31866/2616-7468.3.2.2020.219708

- Shevkani, K., Singh, N., Kaur, A., Rana, J. C. (2014). Physicochemical, Pasting, and Functional Properties of Amaranth Seed Flours: Effects of Lipids Removal. Journal of Food Science, 79 (7), C1271–C1277. doi: https://doi.org/10.1111/1750-3841.12493

- Helikh, A., Danylenko, S., Kryzhska, T., Bovkun, A., Girichenko, S. (2021). Optimization of stability indicators of emulsion-type sauce with added protein isolates of plant origin. Food Resources, 9 (17), 54–64. doi: https://doi.org/10.31073/foodresources2021-17-06

- Gao, D., Helikh, A. O., Filon, A. M., Duan, Z., Vasylenko, O. O. (2022). Effect of Ph-shifting treatment on the gel properties of pumpkin seed protein isolate. Journal of Chemistry and Technologies, 30 (2), 198–204. doi: https://doi.org/10.15421/jchemtech.v30i2.241145

- Tang, C.-H., Sun, X. (2011). A comparative study of physicochemical and conformational properties in three vicilins from Phaseolus legumes: Implications for the structure–function relationship. Food Hydrocolloids, 25 (3), 315–324. doi: https://doi.org/10.1016/j.foodhyd.2010.06.009

- Gao, D., Helikh, A., Duan, Z. (2021). Determining the effect of pH-shifting treatment on the solubility of pumpkin seed protein isolate. Eastern-European Journal of Enterprise Technologies, 5 (11 (113)), 29–34. doi: https://doi.org/10.15587/1729-4061.2021.242334

- Rui, X., Boye, J. I., Ribereau, S., Simpson, B. K., Prasher, S. O. (2011). Comparative study of the composition and thermal properties of protein isolates prepared from nine Phaseolus vulgaris legume varieties. Food Research International, 44 (8), 2497–2504. doi: https://doi.org/10.1016/j.foodres.2011.01.008

- Spackman, D. H., Stein, W. H., Moore, Stanford. (1958). Automatic Recording Apparatus for Use in Chromatography of Amino Acids. Analytical Chemistry, 30 (7), 1190–1206. doi: https://doi.org/10.1021/ac60139a006

- Mariotti, F., Tomé, D., Mirand, P. P. (2008). Converting nitrogen into protein-beyond 6.25 and Jones’ factors. Critical Reviews in Food Science and Nutrition, 48, 177–184. doi: https://doi.org/10.1080/10408390701279749

- Pinheiro, C., Baeta, J. P., Pereira, A. M., Domingues, H., Ricardo, C. P. (2010). Diversity of seed mineral composition of Phaseolus vulgaris L. germplasm. Journal of Food Composition and Analysis, 23 (4), 319–325. doi: https://doi.org/10.1016/j.jfca.2010.01.005

- Hu, H., Fan, X., Zhou, Z., Xu, X., Fan, G., Wang, L. et al. (2013). Acid-induced gelation behavior of soybean protein isolate with high intensity ultrasonic pre-treatments. Ultrasonics Sonochemistry, 20 (1), 187–195. doi: https://doi.org/10.1016/j.ultsonch.2012.07.011

- Wang, H., Hu, D., Ma, Q., Wang, L. (2016). Physical and antioxidant properties of flexible soy protein isolate films by incorporating chestnut (Castanea mollissima) bur extracts. LWT – Food Science and Technology, 71, 33–39. doi: https://doi.org/10.1016/j.lwt.2016.03.025

- Protein and amino acid requirements in human nutrition (2007). World Health Organ technical report series. WHO, 935, 265. Available at: https://apps.who.int/iris/handle/10665/43411

- USDA nutrient database for standard reference (2016). US Department of Agriculture. Available at: http://www.ars.usda.gov/Services/docs.htm?docid=8964

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Tetyana Golovko, Mykola Golovko, Olha Vasilenko, Fedir Pertsevoi, Natalia Bolgova, Vasyl Tischenko, Vladyslav Prymenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.