Experimental studies of the plant raw material drying processes in the conditions of infrared and microwave fields

DOI:

https://doi.org/10.15587/2706-5448.2023.282214Keywords:

drying, dehydration, infrared and microwave radiation, edible vegetable raw materials, experimental modelingAbstract

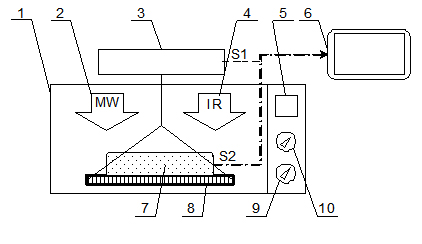

The object of research is the process of drying food plant raw materials. Among the existing methods of drying, convective has become the most common in industry, due to its practicality and ease of organization. However, modern convective drying technologies are accompanied by high-energy consumption, which is a serious problem in the conditions of global energy shortage. An analysis of options for solving drying problems proposed by the scientific community was carried out. The paper presents a solution to the problem through the use of electrodynamic dehydration technologies based on directed energy action. The principle of operation of such technologies is that the electromagnetic field directly interacts with polar molecules, which includes water, which leads to a significant increase in the energy efficiency of the drying process and a reduction in its duration. A set of experimental studies aimed at determining the effect of regime parameters, namely specific power, thickness of the product layer and type of edible vegetable raw materials on the drying process under the conditions of infrared and microwave fields, was carried out. The obtained graphic dependences indicate that the treatment of raw materials with ultra-high frequency radiation significantly reduces the time of the drying process and, as a result, is characterized by a low thermal load on the product, which is a significant advantage when processing heat-labile raw materials. This is due to the deeper penetration of the microwave field (up to 30 mm) compared to infrared (up to 0.003 m). In order to determine the effectiveness of innovative equipment, the paper presents the number of energy action, thanks to which a generalization of the experimental data base was carried out. As a result, criterion equations were obtained, which with an accuracy of ±16 % make it possible to calculate drying devices with infrared and microwave energy sources.

References

- Burdo, O. G. (2010). Evoliutsiia sushilnyh ustanovok. Odesa: Poligraf, 368.

- Qu, F., Zhu, X., Ai, Z., Ai, Y., Qiu, F., Ni, D. (2019). Effect of different drying methods on the sensory quality and chemical components of black tea. LWT, 99, 112–118. doi: https://doi.org/10.1016/j.lwt.2018.09.036

- Zielinska, M., Zielinska, D., Markowski, M. (2017). The Effect of Microwave-Vacuum Pretreatment on the Drying Kinetics, Color and the Content of Bioactive Compounds in Osmo-Microwave-Vacuum Dried Cranberries (Vaccinium macrocarpon). Food and Bioprocess Technology, 11 (3), 585–602. doi: https://doi.org/10.1007/s11947-017-2034-9

- Liu, H., Liu, H., Liu, H., Zhang, X., Hong, Q., Chen, W., Zeng, X. (2021). Microwave Drying Characteristics and Drying Quality Analysis of Corn in China. Processes, 9 (9), 1511. doi: https://doi.org/10.3390/pr9091511

- de Faria, R. Q., dos Santos, A. R. P., Gariepy, Y., da Silva, E. A. A., Sartori, M. M. P., Raghavan, V. (2019). Optimization of the process of drying of corn seeds with the use of microwaves. Drying Technology, 38 (5-6), 676–684. doi: https://doi.org/10.1080/07373937.2019.1686009

- Bahloul, N., Balti, M. A., Guellouze, M. S., Kechaou, N. (2018). Coupling of microwave radiations to convective drying for improving fruit quality. Proceedings of 21th International Drying Symposium. doi: https://doi.org/10.4995/ids2018.2018.7794

- Wei, Q., Huang, J., Zhang, Z., Lia, D., Liu, C., Xiao, Y., Lagnika, C., Zhang, M. (2018). Effects of different combined drying methods on drying uniformity and quality of dried taro slices. Drying Technology, 37 (3), 322–330. doi: https://doi.org/10.1080/07373937.2018.1445639

- Yildiz, G., İzli, G. (2018). Influence of microwave and microwave‐convective drying on the drying kinetics and quality characteristics of pomelo. Journal of Food Processing and Preservation, 43 (6), e13812. doi: https://doi.org/10.1111/jfpp.13812

- Horuz, E., Bozkurt, H., Karataş, H., Maskan, M. (2017). Effects of hybrid (microwave-convectional) and convectional drying on drying kinetics, total phenolics, antioxidant capacity, vitamin C, color and rehydration capacity of sour cherries. Food Chemistry, 230, 295–305. doi: https://doi.org/10.1016/j.foodchem.2017.03.046

- Abbaspour-Gilandeh, Y., Kaveh, M., Fatemi, H., Hernández-Hernández, J. L., Fuentes-Penna, A., Hernández-Hernández, M. (2020). Evaluation of the Changes in Thermal, Qualitative, and Antioxidant Properties of Terebinth (Pistacia atlantica). Fruit under Different Drying Methods. Agronomy, 10 (9), 1378. doi: https://doi.org/10.3390/agronomy10091378

- Burdo, O. G. (2005). Nanoscale effects in food-production technologies. Journal of Engineering Physics and Thermophysics, 78 (1), 90–96. doi: https://doi.org/10.1007/s10891-005-0033-6

- Burdo, O. G., Terziev, S. G., Gavrilov, A. V., Sirotyuk, I. V., Shcherbich, M. V. (2020). System of Innovative Energy Technologies of Food Raw Material Dehydration. Problemele energeticii regionale, 46 (2), 92–107. doi: https://doi.org/10.5281/zenodo.3898317

- Burdo, O. G., Bandura, V. N., Levtrinskaya, Yu. O. (2018). Electrotechnologies of Targeted Energy Delivery in the Processing of Food Raw Materials. Surface Engineering and Applied Electrochemistry, 54 (2), 210–218. doi: https://doi.org/10.3103/s1068375518020047

- Burdo, O., Bandura, V., Zykov, A., Zozulyak, I., Levtrinskaya, J., Marenchenko, E. (2017). Development of wave technologies to intensify heat and mass transfer processes. Eastern-European Journal of Enterprise Technologies, 4 (11 (88)), 34–42. doi: https://doi.org/10.15587/1729-4061.2017.108843

- Burdo, O., Sirotyuk, I., Shcherbich, M., Akimov, A., Poyan, A. (2021). Innovation of Energy Technologies of Food Raw Material Dehydration and Extraction. Problems of the Regional Energetics, 1 (49). doi: https://doi.org/10.52254/1857-0070.2021.1-49.13

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Yevgen Pylypenko, Dmytro Zaporozhets

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.