Assessment of function-technological and rheological parameters of consistency stabilisers for dairy protein-fat systems for the production of semi-smoked sausages

DOI:

https://doi.org/10.15587/2706-5448.2023.283465Keywords:

recipe of semi-smoked sausages, modified starch, carboxyl methyl cellulose, food fibers, iota-carrageenan, milk proteinsAbstract

During the past few years, the world community has faced a number of problems related to the delivery and storage of milk and milk products. In particular, the situation provoked by quarantine restrictions in various countries of the world forces to look for solutions regarding the use of non-traditional raw materials for the production of classic or similar food products. As a result, it is quite promising to use dairy products with extended shelf life, in particular, dry milk concentrates as the main protein carriers for the production of stable protein-fat systems. The use of dry milk proteins makes it possible to manufacture restored structural products that can be used as an alternative to classic ones. Therefore, the object of research is food components of various origins, in particular food modified starches, food fibers and their modifications, hydrocolloids.

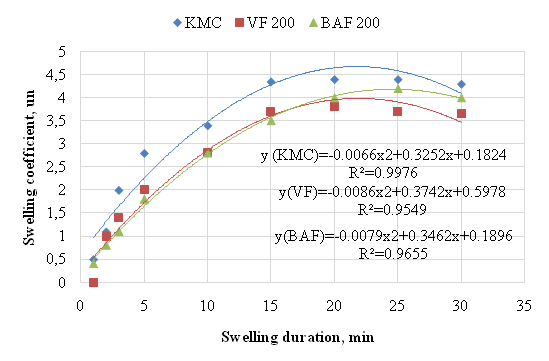

Characteristic indicators of viscosity with increasing shear stress were determined for 5 % solutions of modified starches of various types after brewing at a temperature of 80 °C. It was found that when the shear stress increases to a value of 200 Pa, there is a significant decrease in viscosity, which generally characterizes them as structural systems. The functional and technological indicators of wheat (VF-200), bamboo (BAF-200) food fibers (fiber length 200 microns) and carboxyl methyl cellulose (CMC) were studied. Increased functional and technological capabilities of CMC compared to dietary fibers were revealed. The kinetics of swelling of dietary fibers and CMC were studied, while the period of maximum intensification of the process, which is between 5 and 15 minutes, was determined. The maximum value of the swelling coefficient is characteristic for CMC 4.4±0.04, for wheat fiber 4.01±0.06, for bamboo fiber 3.81±0.05. Using the method of mathematical and statistical processing of experimental data, optimization of concentration and technological modes was carried out to achieve maximum hydration and strength of iota-carrageenan gel. It was determined that at a concentration of 1 % during brewing at 80 °C and a time of 5 min. high enough gel strength can be achieved for optimum consistency in the overall system.

The result of the work is a comprehensive study of the functional technological characteristics of food additives that will form the consistency of a structural protein-fat product of the cheese type, which can be used in sausage products as a filler, with the aim of improving the organoleptic, structural-mechanical and nutritional values of the finished products.

References

- Kamsulina, N. V., Ildirova, S. K., Bolshakova, V. A. (2011). Vykorystannia riznykh vydiv molochnykh preparativ u tekhnolohiiakh kovbasnykh vyrobiv. Prohresyvni tekhnika ta tekhnolohii kharchovykh vyrobnytstv restorannoho hospodarstva i torhivli, 2, 280–288. Available at: https://repo.btu.kharkov.ua/bitstream/123456789/5412/1/Pt_2011_2_44.pdf

- Carter, B., Patel, H., Barbano, D. M., Drake, M. (2018). The effect of spray drying on the difference in flavor and functional properties of liquid and dried whey proteins, milk proteins, and micellar casein concentrates. Journal of Dairy Science, 101 (5), 3900–3909. doi: https://doi.org/10.3168/jds.2017-13780

- Huppertz, T., Gazi, I. (2016). Lactose in dairy ingredients: Effect on processing and storage stability. Journal of Dairy Science, 99 (8), 6842–6851. doi: https://doi.org/10.3168/jds.2015-10033

- Park, C. W., Drake, M. A. (2014). The Distribution of Fat in Dried Dairy Particles Determines Flavor Release and Flavor Stability. Journal of Food Science, 79 (4), R452–R459. doi: https://doi.org/10.1111/1750-3841.12396

- Vega, C., Roos, Y. H. (2006). Invited Review: Spray-Dried Dairy and Dairy-Like Emulsions – Compositional Considerations. Journal of Dairy Science, 89 (2), 383–401. doi: https://doi.org/10.3168/jds.s0022-0302(06)72103-8

- Kozakevych, V. K., Ziuzina, L. S., Kozakevych, O. B. (2018). Adapted milk formulas of domestic production, enriched with oligosaccharides and nucleotides, in the nutrition of infants (review). Bulletin of Problems Biology and Medicine, 4.3 (141), 52–57. doi: https://doi.org/10.29254/2077-4214-2017-4-3-141-52-57

- Borshchenko, V., Kucher, D., Kochuk-Iashchenko, O., Lahovska, O., Marchuk, N. (2021). Otsinka vplyvu zhyvlennia, prohramnoho menedzhmentu hodivli na sklad moloka koriv: literaturnyi ohliad. Bulletin of Sumy National Agrarian University. The Series: Livestock, 2 (45), 62–67. doi: https://doi.org/10.32845/bsnau.lvst.2021.2.9

- Rudiuk, V., Pasichnyi, V., Khorunzha, T., Krasulya, O. (2019). Sour milk product with high protein content. Scientific Messenger of LNU of Veterinary Medicine and Biotechnologies, 21 (91), 79–83. doi: https://doi.org/10.32718/nvlvet-f9113

- Nazarenko, Yu. V., Shmidt, B. V., Bolhova, N. V., Synenko, T. P. (2023). Rozrobka syrnoho produktu iz roslynnym bilkom. Herald of Lviv University of Trade and Economics Technical Sciences, 33, 47–54. doi: https://doi.org/10.36477/2522-1221-2023-33-07

- Bodnarchuk, O. (2017). The influence of stabilizers of the structure on the properties of cream bases for the manufacture of low-earth fat products. Prodovolchi resursy, 5 (9), 120–125. Available at: https://iprjournal.kyiv.ua/index.php/pr/article/view/200/173

- Kulihin, M. L. (2020). Investigation of the influence of quality constitution regulators and the rheological properties of yogurt. Visnyk Khersonskoho natsionalnoho tekhnichnoho universytetu, 2 (73), 41–47.

- Grechko, V., Strashynskiy, I., Pasichnyi, V. (2019). Food fibers as a functional ingredient in the meat semi-products. Technical Sciences and Technologies, 2 (16), 154–164. doi: https://doi.org/10.25140/2411-5363-2019-2(16)-154-164

- Pasichnyi, V. M., Marynin, A. I., Moroz, O. O., Heredchuk, A. M. (2015). Development of combined protein-fat emulsions for sausage and semifinished products with poultry meat. Eastern-European Journal of Enterprise Technologies, 1 (6 (73)), 32–38. doi: https://doi.org/10.15587/1729-4061.2015.36232

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Vitaliy Rudiuk, Vasyl Pasichnyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.