Ensuring the operational-technological characteristics of the new design solution of the sucker-rod pumping unit

DOI:

https://doi.org/10.15587/2706-5448.2023.284032Keywords:

rocking machine, oil production, rods column, strength condition, linear densityAbstract

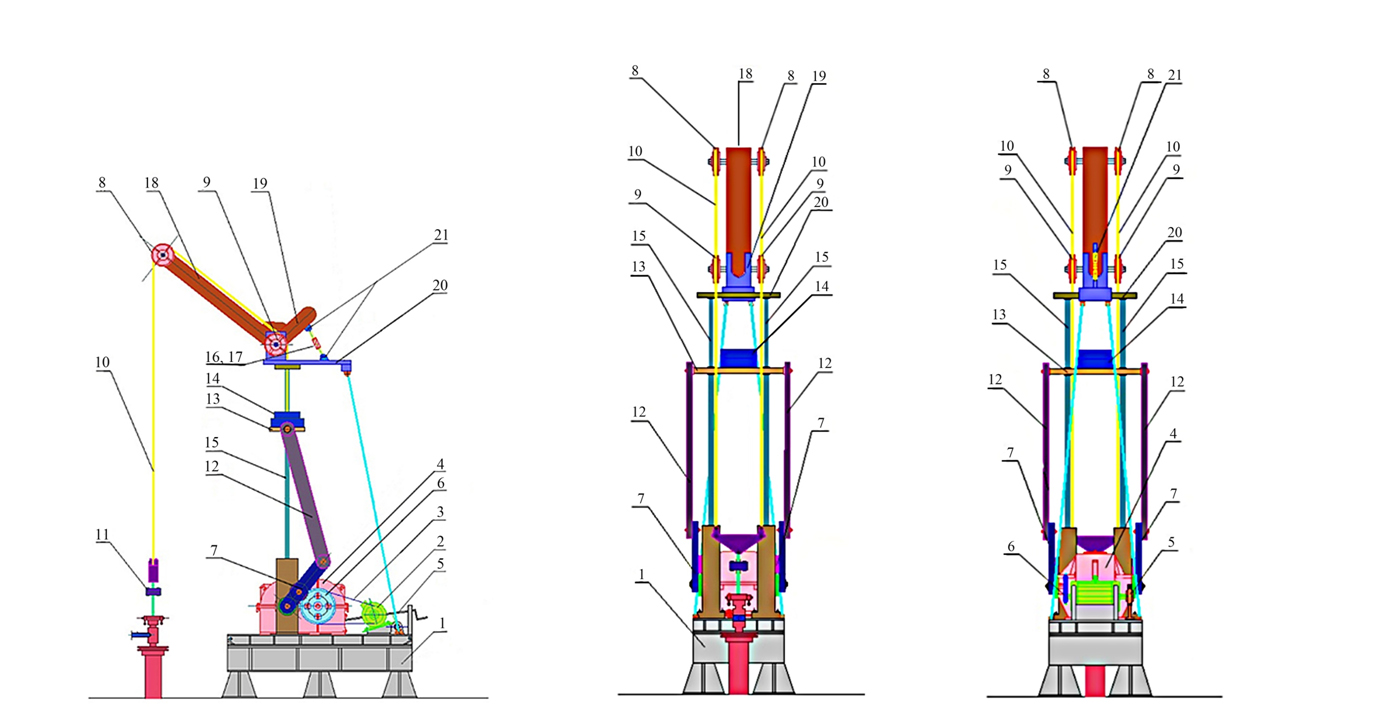

In Azerbaijan oil production is carried out both in the offshore and onshore. Offshore production is carried out on special platforms, while the onshore exploitation carried out directly by a mechanized method. Thus, the object of study is downhole pumps, which consist of a surface mechanical transmission and downhole equipment. For direct mechanization of ground equipment, a device called rocking machine is used, consisting of transmission and converting mechanisms. The main task of the rocking machine is to ensure the conversion of the rotational motion of the engine into the up and down stroke of the plunger of the pump. The downhole equipment includes rods column that lift liquid from the well, a cylinder and a plunger. However, the existing classic rocking machines have some advantages as well as some disadvantages. In order to overcome them, developed new design solution of the sucker-rod pumping unit, which consisting of a crank-rope-movable counterweight system has been designed. As a result of the research carried out in the article, a progressive expression was proposed for determining the strength condition of the rods column, which is one of the main working elements of the rocking machine. Then, in order to specify the wells in which the rocking machine can be applied, the statement regarding the determination of the value of the linear density of liquid column based on the strength condition of the rod column was put forward. These, in turn, can be determined in which oil wells with specific physical characteristics of the rocking machine with the given technical characteristics can be applied. All this can contribute to the prevention of accidents that may occur due to the breakage of the rods column of rocking machine. The formula proposed in this paper can be applied not only to the existing classic rocking machines, but also to other new design of rocking machines.

References

- Janahmadov, A. Kh., Humbatov, H. H., Vahidov, M. A. (1999). Well pumping unit. Baku, 463.

- Mishchenko, I. T. (2003). Well oil production. Publishing House «Oil and Gas» Russian State University of Oil and Gas, 816.

- Gabor, T. (2015). Sucker-Rod Pumping Handbook. Gulf Professional Publishing. doi: https://doi.org/10.1016/c2013-0-05182-1

- Elias, S. K., Rutácio, O. C. (2020). Sucker Rod Pumping: Design, Operation and Maintenance. Independently published, 430.

- Guo, B., Liu, X., Tan, X. (2017). Petroleum Production Engineering. Chapter 16 – Sucker Rod Pumping, 515–548. doi: https://doi.org/10.1016/b978-0-12-809374-0.00016-7

- Li, K., Gao, X., Yang, W., Dai, Y., Tian, Z. (2013). Multiple fault diagnosis of down-hole conditions of sucker-rod pumping wells based on Freeman chain code and DCA. Petroleum Science, 10 (3), 347–360. doi: https://doi.org/10.1007/s12182-013-0283-4

- Zhanyu, G. E. (1998). Statistical analysis of sucker rod pumping failures in the permian basin. A thesis in petroleum engineering, 170.

- Kumar, A., Upadhyay, R., Kumar, S. (2022). Tubing and Rod Failure Analysis in Rod Pumped Wells in an Indian Western Oil Field. SPE Journal, 28 (3), 1481–1501. doi: https://doi.org/10.2118/212848-pa

- Ramez, A. (2018). Automatıc well failure analysis for the sucker rod pumpıng systems. Giza, 105.

- Evstifeev, V. G. (2017). Increasing the Reliability, Service Life, and Ecological Safety of the Stuffing Boxes of Wellhead Equipment of Wells that Operate by Means of Deep-Well Sucker-Rod Pumping Units. Chemical and Petroleum Engineering, 53 (7-8), 484–487. doi: https://doi.org/10.1007/s10556-017-0368-9

- Najafov, A. M. (2013). Exploratory design of a mechanical drive of sucker-rod pumps. Palmarium Academic Publishing, 135.

- Abdullaev, A. I., Najafov, A. M., Ahmedov, B. B., Chelebi, I. G., Abdullaev, A. A., Hajiyev, A. B. (2022). Eurasian patent for invention No. 039650. Mechanical drive of sucker-rod pumping unit.

- Abdullaev, A. I., Najafov, A. M., Ahmedov, B. B., Chelebi, I. G., Abdullaev, A. A., Hajiyev, A. B. (2021). Azerbaijan Intellectual Property Agency patent for invention No. a2019 0162. Mechanical drive of sucker-rod pumping unit.

- Hajiyev, A. (2020). About new constructive solution of sucker-rod oil pumping unit. Topical Issues of Rational Use of Natural Resources. St Petersburg, Vol. 1. EDN KETGHE. Saint Petersburg: Saint Petersburg Mining University, 29–30.

- Gesslbauer, H., Eisner, P., Langbauer, C., Knauhs, P. et al. (2021). Sucker rod pump performance in polymer back-producing wells – simulation, laboratory and field testing. EEK journal, 9, 14–19.

- Leiming, L., Chaonan, T., Jianqin, W., Ranbing, L. (2004). A Uniform and Reduced Mathematical Model for Sucker Rod Pumping. International Conference on Computational Science – ICCS 2004, 372–379. doi: https://doi.org/10.1007/978-3-540-24687-9_47

- Denney, D. (2001). Laboratory-Instrumented Sucker-Rod Pump. Journal of Petroleum Technology, 53 (5), 50–51. doi: https://doi.org/10.2118/0501-0050-jpt

- Araújo, R. R. F., Xavier-de-Souza, S. (2021). A simulation model for dynamic behavior of directional sucker-rod pumping wells: implementation, analysis, and optimization. Journal of Petroleum Exploration and Production Technology, 11 (6), 2635–2659. doi: https://doi.org/10.1007/s13202-021-01161-x

- Fakher, S., Khlaifat, A., Hossain, M. E., Nameer, H. (2021). A comprehensive review of sucker rod pumps’ components, diagnostics, mathematical models, and common failures and mitigations. Journal of Petroleum Exploration and Production Technology, 11 (10), 3815–3839. doi: https://doi.org/10.1007/s13202-021-01270-7

- Stanghelle, K. U. (2009). Evaluation of artificial lift methods on the Gyda field. Stavanger: University of Stavanger, 97.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Beyali Ahmedov, Isa Khalilov, Anar Hajiyev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.