Development of improved technology for producing graphene-like coating by LPCVD method

DOI:

https://doi.org/10.15587/2706-5448.2023.286318Keywords:

graphene, oxygraphene, coating, LPСVD method, CVD method, microstructure, Raman spectroscopy, densityAbstract

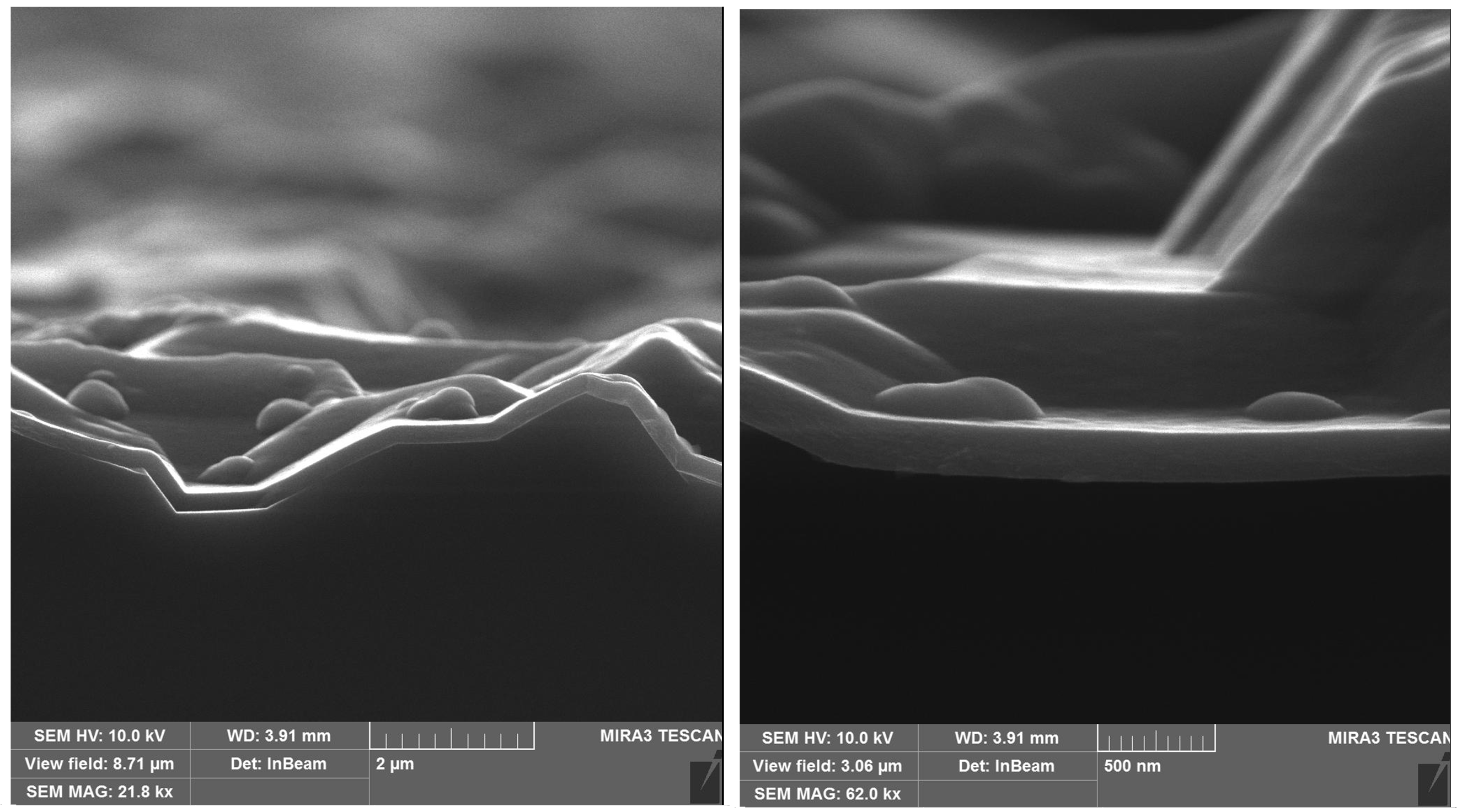

The object of research in this work was the coating of oxygraphene on a silicon single crystal substrate. In the work, the LPСVD (Low Pressure Chemical Vapor Deposition) method of deposition from the gas phase at low pressure is used to obtain graphene-like coatings on heat-resistant materials. A feature of the proposed LPCVD method in comparison with the classical method of deposition from the gas phase CVD (Chemical Vapor Deposition) by the method of catalytic decomposition of carbon-containing gas followed by the deposition of a graphene-like coating on a copper template is the use of a higher partial gas pressure, which leads to the deposition of graphene-like waste not only on the surface of the copper template-catalyst, but also in the entire volume of the reaction chamber and the materials introduced into it. A monocrystalline silicon template was used as a model for coating. The resulting coatings of different thicknesses were examined by scanning electron microscopy, Raman spectroscopy, and density was assessed by helium pycnometry. Based on the analysis of the results obtained using the method of scanning electron microscopy, the possibility of varying the thickness of the oxygraphene coating was shown. In addition, the formation of oxygraphene on a silicon single crystal substrate was confirmed by the Raman spectroscopy method, namely the presence of characteristic peaks in the spectra of the studied materials. Using the helium pycnometry method, a decrease in the density of the coated material from 2.25 g/cm3 to 2.08 g/cm3 was found. It was established that the greater the coating thickness, the lower the density. The general analysis showed that the developed LPСVD technology allows obtaining an oxygraphene coating on materials of any shape, porosity, size and resistant to temperatures above 600 °С in order to functionalize their surface and improve and improve their properties.

References

- Zhang, F., Yang, K., Liu, G., Chen, Y., Wang, M., Li, S., Li, R. (2022). Recent advances on graphene: Synthesis, properties and applications. Composites Part A: Applied Science and Manufacturing, 160, 107051. doi: https://doi.org/10.1016/j.compositesa.2022.107051

- Zeng, H., Qu, S., Tian, Y., Hu, Y., Li, Y. (2023). Recent progress on graphene oxide for next-generation concrete: Characterizations, applications and challenges. Journal of Building Engineering, 69, 106192. doi: https://doi.org/10.1016/j.jobe.2023.106192

- Janavika, K. M., Prakash Thangaraj, R. (2023). Graphene and its application: A review. Materials Today: Proceedings. doi: https://doi.org/10.1016/j.matpr.2023.05.446

- Singh, J., Jindal, N., Kumar, V., Singh, K. (2023). Role of green chemistry in synthesis and modification of graphene oxide and its application: A review study. Chemical Physics Impact, 6, 100185. doi: https://doi.org/10.1016/j.chphi.2023.100185

- Liu, J., Chen, S., Liu, Y., Zhao, B. (2022). Progress in preparation, characterization, surface functional modification of graphene oxide: A review. Journal of Saudi Chemical Society, 26 (6), 101560. doi: https://doi.org/10.1016/j.jscs.2022.101560

- Kartel, M. T. (2019). Formuvannia struktury ta vlastyvostei sp2-vuhletsevykh nanomaterialiv i funktsionalnykh kompozytiv za yikh uchasti. Kyiv: Instytut khimii poverkhni im. O. O. Chuika NAN Ukrainy; TOV «NVP Interservis», 364.

- Wick, P., Louw-Gaume, A. E., Kucki, M., Krug, H. F., Kostarelos, K., Fadeel, B. et al. (2014). Classification Framework for Graphene-Based Materials. Angewandte Chemie International Edition, 53 (30), 7714–7718. doi: https://doi.org/10.1002/anie.201403335

- Iatsenko, A., Sych, O., Synytsia, A., Zaremba, P., Zahorodnia, S., Nikolenko, A., Tomila, T., Bykov, O. (2023). Structure and properties of biogenic hydroxyapatite bioceramics modified by graphene-like structures. Applied Nanoscience. doi: https://doi.org/10.1007/s13204-023-02927-x

- Slobodian, O. M., Lytvyn, P. M., Nikolenko, A. S., Naseka, V. M., Khyzhun, O. Yu., Vasin, A. V. et al. (2018). Low-Temperature Reduction of Graphene Oxide: Electrical Conductance and Scanning Kelvin Probe Force Microscopy. Nanoscale Research Letters, 13 (1). doi: https://doi.org/10.1186/s11671-018-2536-z

- Kaniyoor, A., Ramaprabhu, S. (2012). A Raman spectroscopic investigation of graphite oxide derived graphene. AIP Advances, 2 (3). doi: https://doi.org/10.1063/1.4756995

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Artem Iatsenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.