Study of the operating parameters of vibrations of a vibrosieve of the washing liquid purification unit

DOI:

https://doi.org/10.15587/2706-5448.2023.286362Keywords:

vibrosieve, natural oscillation frequency, drilling fluid, drilled rock, working body, mechanical oscillationsAbstract

The object of the research is elastic plates located across the movement of the solution on the vibrosieve. The problem of uniform distribution of material on the surface of the sieve is considered, which is solved with the help of the design proposed in the work.

Tensometry was used as a research method with subsequent processing of the results on an elector computer. In the course of the research, an analog-to-digital converter developed and manufactured at the Department of Mechanization of Construction Processes of the National University «Yuri Kondratyuk Poltava Polytechnic» (Ukraine) was used. As well as a computer with a free COM-1 port, «PROGRAM.EXE» software and a spreadsheet editor, strain gauges in the form of strain gauges with two pasted tensor resistors connected by a half-bridge circuit.

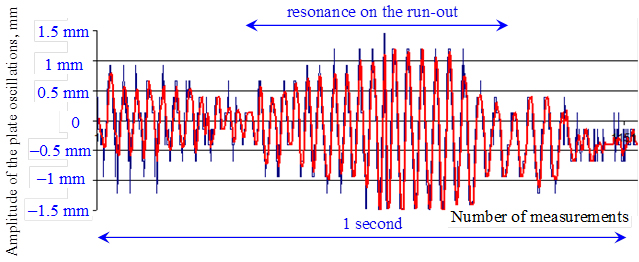

The paper proposes a fundamentally new scheme of a vibrosieve with additional working bodies in the form of elastic plates located across the movement of the solution on the sieve. The elasticity and mass of the plates are selected in such a way that their oscillations during the operation of the vibrosieve exciter are close to resonance. At the same time, the mode of vibration of the vibrosieve itself is far beyond resonance. As a result, a higher-quality and energy-efficient cleaning of the washing liquid will be obtained. This is due to the fact that the proposed cleaning method has a number of features, in particular, dispersion of drilling fluid over the entire surface of the vibrosieve and maximum loading of the entire working surface of the sieve to avoid dead zones. Thanks to this, it is possible to obtain resonant oscillations. In comparison with known analogs that work in a resonant mode, this provides advantages in the cleaning of drilling mud. The amplitude of oscillations of elastic plates reaches 1.2–1.5 mm, which is significantly greater than the amplitude of oscillations of a vibrating table.

In practice, it will be possible to use the proposed fundamentally new scheme of a vibrosieve with additional working bodies in the form of elastic plates that work in a resonant mode, as a way of supplementing vibrosieves that are in use or new when manufactured at manufacturers' factories.

References

- Sito vibratcionnoe LVS-1M, LVS-2M, LVS-3M. Available at: http://fluitech.com.ua/assets/files/odbu/lvs.pdf

- Chen, Y., Tong, X. (2010). Modeling screening efficiency with vibrational parameters based on DEM 3D simulation. Mining Science and Technology (China), 20 (4), 615–620. doi: https://doi.org/10.1016/s1674-5264(09)60254-4

- Dong, K., Esfandiary, A. H., Yu, A. B. (2017). Discrete particle simulation of particle flow and separation on a vibrating screen: Effect of aperture shape. Powder Technology, 314, 195–202. doi: https://doi.org/10.1016/j.powtec.2016.11.004

- Raja, V., Chase, G. G., Jones, B. N., Geehan, T., Swaco, M. (2012). Computational modeling and experiments on shale shaker performance. AADE-12-FTCE-58.

- Nesterenko, M., Nazarenko, I., Molchanov, P. (2018). Cassette Installation with Active Working Body in the Separating Partition. International Journal of Engineering&Technology, 7 (3.2), 265–268. doi: https://doi.org/10.14419/ijet.v7i3.2.14417

- Lyakh, M. M., Savyk, V. M., Molchanov, P. O. (2016). Improving the efficiency of foamgenerating devices of pump-circulative systems of drilling sets. Rozrobka rodovyshch korysnykh kopalyn. Naukovyi visnyk NHU, 3, 23–30.

- Liakh, M. M., Fedoliak, N. V., Reiti, O. O. (2016). Vyznachennia zhorstkosti vibroopor burovykh vibrosyt. Aktualni zadachi suchasnykh tekhnolohii. Ternopil: TNTU, 46–47.

- Krot, O. Yu., Korobko, B. O., Krot, O. P., Virchenko, V. V. (2023). Eksperymentalni metody doslidzhen. Poltava: NUPP, 192.

- Krot, A., Ruchka, A., Savchenko, A., Krot, O., Supryaga, D. (2018). Analytical Modeling of Oscillations of Movable Operating Elements of a Roll-Drum Activator. International Journal of Engineering & Technology, 7 (4.3), 58–63. doi: https://doi.org/10.14419/ijet.v7i4.3.19552

- Nascentes, C. L., Murata, V. V., Oliveira-Lopes, L. C. (2022). Mathematical modeling of solids-drilling fluid separation in shale shakers in oil fields: A state of art review. Journal of Petroleum Science and Engineering, 208, 109270. doi: https://doi.org/10.1016/j.petrol.2021.109270

- Sivko, V. Ya., Scubok, E. O. (1998). Motion of a dynamic system taking into account the internal resistance of the medium. Vibrotechnology – 98. Treatment of dispersed materials and media. Theory, research. Technology and equipment. Kyiv: NGO VOTUM, 16–21.

- Banakh, L., Kempner, M. (2010). Vibrations of Mechanical Systems with Regular Structure. Berlin, Heidelberg: Springer. doi: https://doi.org/10.1007/978-3-642-03126-7

- Nesterenko, M. P., Molchanov, P. O., Savyk, V. M., Nesterenko, M. M. (2019). Vibration platform for forming large-sized reinforced concrete products. Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 5, 74–78. doi: https://doi.org/10.29202/nvngu/2019-5/8

- Surzhko, T. O., Savyk, V. M., Molchanov, P. O., Kaliuzhnyi, A. P. (2020). Pidvyshchennia efektyvnosti roboty obladnannia bloku ochyshchennia promyvalnoi ridyny. Zb. nauk. prats Natsionalnoho universytetu «Poltavska politekhnika imeni Yuriia Kondratiuka» (haluzeve mashynobuduvannia, budivnytstvo), 2 (55), 121–127.

- Surzhko, T. O., Molchanov, P. O., Savyk, V. M., Aheicheva, O. O. (2020). Statychnyi rozrakhunok robochykh poverkhon obladnannia dlia ochystky burovoho rozchynu za metodom skinchennykh elementiv. XIII Mizhnarodnoi naukovo-praktychnoi konferentsii «Akademichna y universytetska nauka – rezultaty ta perspektyvy». Poltava.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Tetiana Surzhko, Maksym Knysh, Yurij Kuzub, Oleksandr Kruchkov, Vyacheslav Rubel

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.