Study of temperature changes in mineral fertiliser granules after contact with air in a granulation tower

DOI:

https://doi.org/10.15587/2706-5448.2023.286693Keywords:

granule, urea, pouring, rotating vibrating granulator, convective cooling, heat exchange, thermal conductivity, temperature profileAbstract

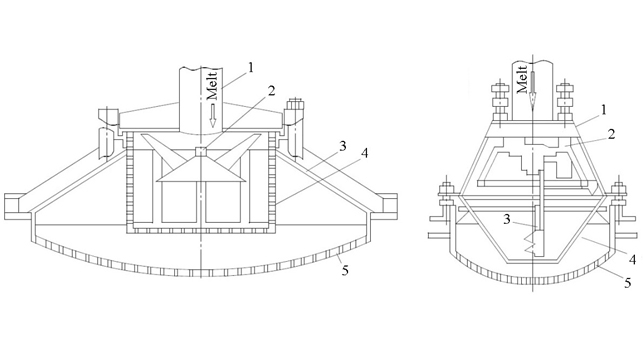

The object of research is the process of granulation of nitrogen mineral fertilizers by the method of sprinkling. One of the most problematic areas is the lack of certainty regarding the dynamics of the temperature change of the granule when it is cooled by air in the granulation tower. The paper considers the process of urea granulation using a rotating vibrating granulator. The scheme of the rotating vibrating granulator as part of the experimental stand for granulating liquid urea is presented, the method of conducting experimental studies and the design parameters of the granulator are described. It is indicated that in the process of experimental research, the temperatures of the melt, granules and cooling air were recorded. It is emphasized that the contact of the cooling air with the flow of hot granules leads to a constant increase in air temperature due to the heat transferred from the granules, which makes it necessary to determine the final temperature of the air leaving the granulation tower. For this purpose, a mathematical model was developed and calculation equations were obtained to determine the temperature of the air in contact with the surface of the pellet and the temperature profile inside the pellet. Numerical calculations of the calculation equations made it possible to obtain temperature profiles of the granule along its radius. It is emphasized that the theoretically obtained temperature profile cannot be an accurate indicator of the real temperature of the pellet when it falls in the granulation tower. Analysis of the calculated results shows that the temperature of the granules in the lower part of the granulation tower is 60–62 °C. This temperature corresponds to the practically confirmed final temperature of the granule, which was measured on the experimental stand.

Supporting Agency

- This research work has been supported by the project VEGA 1/0500/20 «Investigation of mechanical properties of materials with complex internal structure by numerical and experimental methods of mechanics» granted by the Ministry of Education, Science, Research and Sport of the Slovak Republic and project «Fulfillment of tasks of the perspective plan of development of a scientific direction «Technical sciences» Sumy State University» (State Reg. No. 0121U112684) funded by the Ministry of Education and Science and of Ukraine.

References

- Jarchow, M. E., Liebman, M. (2012). Nitrogen fertilization increases diversity and productivity of prairie communities used for bioenergy. GCB Bioenergy, 5 (3), 281–289. doi: https://doi.org/10.1111/j.1757-1707.2012.01186.x

- DSTU 7312:2013. Sechovyna (karbamid). Tekhnichni umovy (2013). Kyiv: Minekonomrozvytku Ukrainy, 22.

- Baboo, P. (2021). Prilling tower and granulator heat and mass transfer. Journal of Global Optimization, 9 (1).

- Skydanenko, M., Sklabinskyi, V., Nadhem, A.-K. M., Nichvolodin, K. (2021). Determination of granule (prill) movement modes in the prilling tower for mineral fertilizer production. Technology Audit and Production Reserves, 5 (3 (61)), 6–9. doi: https://doi.org/10.15587/2706-5448.2021.241142

- Method for transforming a prilling section including a prilling tower, in particular in a plant for the synthesis of urea (2016). European patent specification. No. Publication: 28.09.2016. Bul. No. 2016/39.

- Gezerman, A. O. (2020). Mathematical modeling for prilling processes in ammonium nitrate production. Engineering Reports, 2 (6). doi: https://doi.org/10.1002/eng2.12173

- Yurchenko, O., Ostroha, R., Sklabinskyi, V., Gusak, O., Bocko, J. (2023). Formation of Liquid Droplets at the Prilling Bucket Outlet Under Free Oscillations of the Liquid Jet. Advances in Design, Simulation and Manufacturing VI, 177–185. doi: https://doi.org/10.1007/978-3-031-32774-2_18

- Alamdari, A., Jahanmiri, A., Rahmaniyan, N. (2000). Mathematical modelling of urea prilling process. Chemical Engineering Communications, 178 (1), 185–198. doi: https://doi.org/10.1080/00986440008912182

- Rahmanian, N., Homayoonfard, M., Alamdari, A. (2013). Simulation of urea prilling process: an industrial case study. Chemical Engineering Communications, 200 (6), 764–782. doi: https://doi.org/10.1080/00986445.2012.722147

- Gurney, C. J., Simmons, M. J. H., Hawkins, V. L., Decent, S. P. (2010). The impact of multi-frequency and forced disturbances upon drop size distributions in prilling. Chemical Engineering Science, 65 (11), 3474–3484. doi: https://doi.org/10.1016/j.ces.2010.02.030

- Abbasfard, H., Rafsanjani, H. H., Ghader, S., Ghanbari, M. (2013). Mathematical modeling and simulation of an industrial rotary dryer: A case study of ammonium nitrate plant. Powder Technology, 239, 499–505. doi: https://doi.org/10.1016/j.powtec.2013.02.037

- Mehrez, A., Ali, A. H. H., Zahra, W. K., Ookawara, S., Suzuki, M. (2012). Study on Heat and Mass Transfer During Urea Prilling Process. International Journal of Chemical Engineering and Applications, 3 (5), 347–353. doi: https://doi.org/10.7763/ijcea.2012.v3.216

- Saleh, S. N., Ahmed, S. M., Al-mosuli, D., Barghi, S. (2015). Basic design methodology for a prilling tower. The Canadian Journal of Chemical Engineering, 93 (8), 1403–1409. doi: https://doi.org/10.1002/cjce.22230

- Saleh, S. N., Barghi, S. (2016). Reduction of fine particle emission from a prilling tower using CFD simulation. Chemical Engineering Research and Design, 109, 171–179. doi: https://doi.org/10.1016/j.cherd.2016.01.017

- Sharma, S. P., Garg, H. (2011). Behavioural analysis of urea decomposition system in a fertiliser plant. International Journal of Industrial and Systems Engineering, 8 (3), 271–297. doi: https://doi.org/10.1504/ijise.2011.041539

- Luikov, A. (1968). Analytical heat diffusion theory. New York: Academic. doi: https://doi.org/10.1016/b978-0-12-459756-3.x5001-9

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Al-Khyatt Muhamad Nadhem, Vsevolod Sklabinsky, Ruslan Ostroha, Maksym Skydanenko, Mykola Yukhymenko, Jozef Bocko, Denys Ostroha, Dmitry Zabitsky, Oleksii Moskalchuk, Andrii Serhiienko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.