Analysis of the possibilities of increasing the energy efficiency of absorption refrigeration appliances through the use of refrigerating accumulators

DOI:

https://doi.org/10.15587/2706-5448.2023.286709Keywords:

environment, absorption refrigeration, ozone reduction, absorption freezer, cold accumulator, energy efficiencyAbstract

One of the most important tasks of modern society is the solution of environmental and energy problems in power engineering and, in particular, refrigeration technology. At the same time, in the field of artificial cooling systems, it is necessary to solve the problems of reducing the impact on both the ozone layer and the greenhouse effect. An effective approach here can be absorption refrigeration systems with a natural working fluid (water-ammonia solution), which does not adversely affect the environment. For the effective use of absorption refrigeration systems, it is necessary to solve the problems of increasing their energy efficiency, in particular, through the use of cold accumulators. Thus, the object of research is absorption-type cooling systems with cold accumulators.

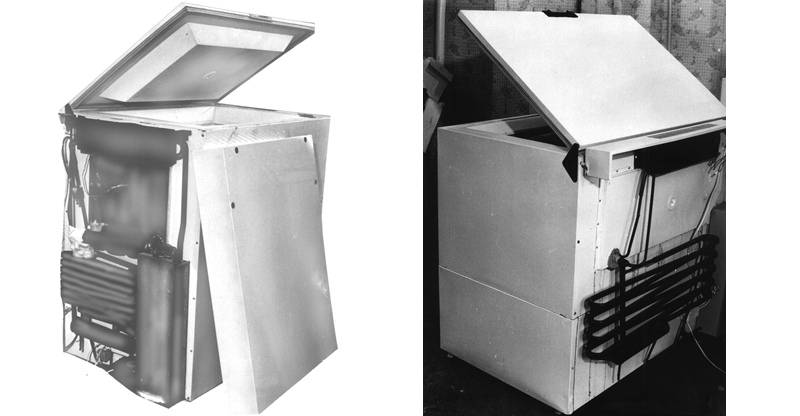

The paper analyzes cold accumulators with different physical nature. It is shown that melting substances can be the most effective for solving problems of low-temperature cooling. An analysis of the thermal scheme of an absorption freezer of the «chest» type, which is the most problematic in terms of providing cooling modes at a level of (–18)–(–24) °С, was carried out. Optimization thermal calculations for typical absorption freezers up to 200 dm3 have been performed. It is shown that when the chamber is initially loaded with a product at an ambient temperature, the cooling capacity of the installed absorption refrigeration units is not enough – no more than 50 % of the required one. For an absorption freezer of the «chest» type, the most suitable cold-storage materials are a eutectic aqueous solution of sodium chloride or propylene glycol, since these solutions have the desired melting point of the order of –18 °C and a fairly high melting heat. The result of optimizing the weight and size characteristics of the internal volume of the absorption freezer is the following recommendations:

– the optimal size of wire baskets for placing products is 315´370´240 mm;

– the gaps between the basket and the cabinet wall, as well as between the baskets themselves, should be 10 mm to ensure normal convection conditions;

– it is not advisable to place fans inside the volume of the freezer at this stage, since the freezing time is reduced by a maximum of 30 %, but this results in additional heat generation, energy consumption and increases the shrinkage of the products stored in the chamber.

References

- Commission of the European DGXVII. The European renewable energy study. Office for Official Publications of the European Communities. Luxembourg, 1, 38.

- Consoli, F. (1993). Guidelines for life cycle assessment: A code of practice. Society of Environmental Toxicology and Chemistry workshop report. Sesimbra.

- Montreal Protocol on Substances That Deplete the Ozone Layer (1987). Final Act. UNEP, 6.

- McMullan, J. T. (2002). Refrigeration and the environment – issues and strategies for the future. International Journal of Refrigeration, 25 (1), 89–99. doi: https://doi.org/10.1016/s0140-7007(01)00007-x

- Bolina, B., Deesa, B. R., Iagera, Dzh., Uorrika, R. (1989). Parnikovyi effekt, izmenenie klimata i ekosistemy. Leningrad: Gidrometeoizdat, 558.

- DSTU 2295-93 (HOST 16317-95 ISO 5155-83, ISO 7371-85, IEC 335-2-24-84). Prylady kholodylni elektrychni pobutovi. Zahalni tekhnichni umovy (1996). Kyiv: Derzhstandart Ukrainy, 35.

- Zheleznyi, V. P., Khlieva, O. Ia., Bykovetc, N. P. (2001). Uchet emissii parnikovykh gazov pri formirovanii indikatorov dlia ekologo-energeticheskogo audita v kholodilnoi promyshlennosti. Ekotekhnologii i resursosberezhenie, 4, 51–58.

- Dincer, I., Ratlamwala, T. A. (2016). Developments in Absorption Refrigeration Systems. Integrated Absorption Refrigeration Systems Green Energy and Technology, 241–257. doi: https://doi.org/10.1007/978-3-319-33658-9_8

- Titlov, A. S. (1997). Sravnenie kharakteristik absorbtcionnoi i kompressionnoi bytovoi kholodilnoi tekhniki. Kholodilnaia tekhnika i tekhnologiia, 57, 39–41.

- Titlov, O. S., Vasyliv, O. B. (1998). Vartisni ta ekolohichni ekspluatatsiini kharakterystyky aparativ pobutovoi kholodylnoi tekhniky v Ukraini i krainakh YeES. Rynok instaliatsiinyi, 9, 18–20.

- Zolfagharkhani, S., Zamen, M., Shahmardan, M. M. (2018). Thermodynamic analysis and evaluation of a gas compression refrigeration cycle for fresh water production from atmospheric air. Energy Conversion and Management, 170, 97–107. doi: https://doi.org/10.1016/j.enconman.2018.05.016

- Babakyn, B. S., Vyhodyn, V. A. (1998). Bytovye kholodylnyky y morozylnyky. Moscow: Kolos, 631.

- Titlov, A. S., Zakharov, N. D. (2007). Sovremennyi uroven proizvodstva bytovykh absorbtcionnykh kholodilnykh priborov. Naukovі pratcі ONAKhT, 2 (31), 62–67.

- Titlov, A. S. (2008). Povyshenie energeticheskoi effektivnosti absorbtcionnykh kholodilnykh priborov. Naukovі pratcі ONAKhT, 1 (34), 295–303.

- Alekseev, V. A. (1975). Okhlazhdenie radioelektronnoi apparatury s ispolzovaniem plaviashchikhsia veshchestv. Moscow: Energiia, 88.

- Danilin, V. N. (1981). Fizicheskaia khimiia teplovykh akkumuliatorov. Krasnodar: Izd-vo Krasnodar. politekh. in-ta, 90.

- DSTU 3023-95 (HOST 30204-95, ISO 5155-83, ISO 7371-85, ISO 8187-91). Prylady kholodylni pobutovi. Ekspluatatsiini kharakterystyky ta metody vyprobuvan (1996). Kyiv: Derzhstandart Ukrainy, 22.

- Isachenko, V. P., Osipova, V. A., Sukomel, A. S. (1981). Teploperedacha. Moscow: Energiia, 416.

- Dulnev, G. N. (1984). Teplo- i massoobmen v radioelektronnoi apparature. Moscow: Vysshaia shkola, 247.

- Chumak, I. G., Nikulshina, D. G. (1988). Kholodilnye ustanovki. Proektirovanie. Kyiv: Vysshaia shkola, 280.

- Rodríguez-Muñoz, J. L., Belman-Flores, J. M. (2014). Review of diffusion–absorption refrigeration technologies. Renewable and Sustainable Energy Reviews, 30, 145–153. doi: https://doi.org/10.1016/j.rser.2013.09.019

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Liudmyla Berezovska, Oleksandr Titlov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.