Adaptive method of estimating the dynamic characteristics of the bottom pressing process when making disposable casting molds

DOI:

https://doi.org/10.15587/2706-5448.2023.288152Keywords:

sand mold, press molding machines, compaction of molding mixture, bottom pressing, foundry equipment, D-optimal plansAbstract

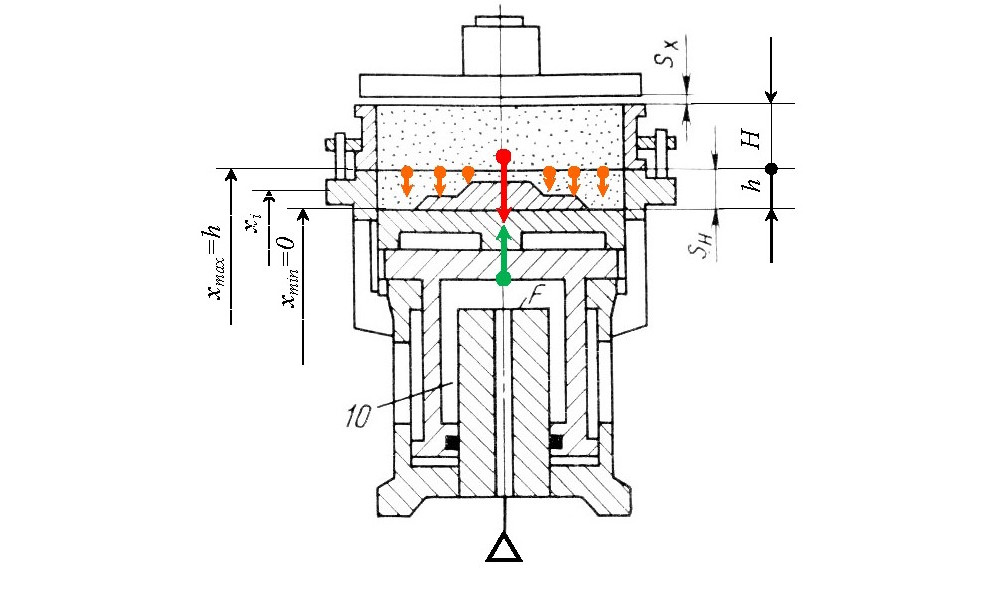

The object of research in the paper is the process of bottom pressing in the manufacture of disposable sand molds.

The existing problem is that in practical conditions it is almost impossible to determine the forces acting in the molding mixture in the process of lower pressing. This leads to the fact that in the real process, with the selected pressing modes, the requirements regarding the density of the mixture in the furnace during the manufacture of the half-form may not be met.

To solve this problem, it is proposed to build a method that does not require measurement of effort in the system, but allows to obtain dynamic characteristics of the pressing process based on an adaptive approach to determining the technological effort.

It is hypothesized that it is possible to evaluate the dynamic characteristics of the compaction process in an industrial process without measuring the forces acting in the system during lower pressing. This can be done regardless of which drive is used - pneumatic or hydraulic.

It is demonstrated how the kinematic characteristics of the process can be determined based on the use of D-optimal plans on a segment.

The proposed method includes 12 points that involve the implementation of experimental and industrial studies directly on the operating equipment based on the use of D-optimal plans and further adaptation of the process of finding the force acting on the molding mixture. The adaptation is based on a preliminary assessment of the kinematic characteristics of the pressing process and involves the calculation of the technological effort that ensures the achievement of the given time of the coordinate of the lower plane of the molding mixture obtained from the equation of kinetics.

The results of the implementation of the method make it possible to identify different stages of the pressing process and the distribution of the density of the mixture along the height of the column of the molding mixture.

The practical implementation of the method can help in setting up the control system of the lower pressing process depending on the equipment parameters. Therefore, the presented research will be useful for machine-building enterprises that have foundries in their structure, where shaped castings are made in one-time sand molds.

References

- Frolova, L., Barsuk, A., Nikolaiev, D. (2022). Revealing the significance of the influence of vanadium on the mechanical properties of cast iron for castings for machine-building purpose. Technology Audit and Production Reserves, 4 (1 (66)), 6–10. doi: https://doi.org/10.15587/2706-5448.2022.263428

- Zynchenko, P. S., Aksenenko, M. P., Yovbak, A. V., Orendarchuk, Yu. V. (2016). Application of liquid glass mixtures with reduced content of liquide glass as a factor in improving the quality of machine-building castings. ScienceRise, 5 (2 (22)), 6–9. doi: https://doi.org/10.15587/2313-8416.2016.69836

- Zynchenko, P. S., Holynkov, V. V., Starikh, S. A., Stupar, M. A. (2016). Optimization of thermal drying of liquid glass mixture according to tensile strength criterion. ScienceRise, 6 (2 (23)), 9–13. doi: https://doi.org/10.15587/2313-8416.2016.69970

- ElMaraghy, W., ElMaraghy, H., Tomiyama, T., Monostori, L. (2012). Complexity in engineering design and manufacturing. CIRP Annals, 61 (2), 793–814. doi: https://doi.org/10.1016/j.cirp.2012.05.001

- ElMaraghy, W. H., Urbanic, R. J. (2003). Modelling of Manufacturing Systems Complexity. CIRP Annals, 52 (1), 363–366. doi: https://doi.org/10.1016/s0007-8506(07)60602-7

- Joshi, D., Ravi, B. (2010). Quantifying the Shape Complexity of Cast Parts. Computer-Aided Design and Applications, 7 (5), 685–700. doi: https://doi.org/10.3722/cadaps.2010.685-700

- Budiono, H. D. S., Nurdian, D., Indianto, M. A., Nugroho, H. S. (2022). Development of a process complexity index of low pressure die casting for early product design evaluation. Eastern-European Journal of Enterprise Technologies, 6 (1 (120)), 101–108. doi: https://doi.org/10.15587/1729-4061.2022.264984

- Trung, P. Q. (2023). Simulation and experimental study on the Fenotec casting method of the engine block RV95. EUREKA: Physics and Engineering, 5, 115–121. doi: https://doi.org/10.21303/2461-4262.2023.002791

- Frolova, L. V. (2011). Identification provision of energy saving on the basis of audit process moulding machines shaking. Technology Audit and Production Reserves, 2 (2 (2)), 8–13. doi: https://doi.org/10.15587/2312-8372.2011.4859

- Frolova, L. V. (2012). Choice of ways to improve design elements of machines moulding shaking. Technology Audit and Production Reserves, 1 (1 (3)), 30–34. doi: https://doi.org/10.15587/2312-8372.2012.4873

- Kastengebundene Formmaschinen und –anlagen. Available at: https://www.wagner-sinto.de/produkte/kastengebundene-formmaschinen-und-anlagen/

- Formatrice brap6 a pestelli multipli. Available at: https://www.belloi.it/impianti.php?id=12

- Belikov, O. A., Kashirtcev, L. P. (1971). Privody liteinykh mashin. Moscow: Mashinostroenie, 311.

- Demin, D. (2023). Experimental and industrial method of synthesis of optimal control of the temperature region of cupola melting. EUREKA: Physics and Engineering, 2, 68–82. doi: https://doi.org/10.21303/2461-4262.2023.002804

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Vitalii Lysenkov, Dmitriy Demin

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.