Production of white cement by low-temperature firing

DOI:

https://doi.org/10.15587/2706-5448.2023.290427Keywords:

white cement, raw material mixture, low-temperature firing, phase composition, silica-containing component, colored oxidesAbstract

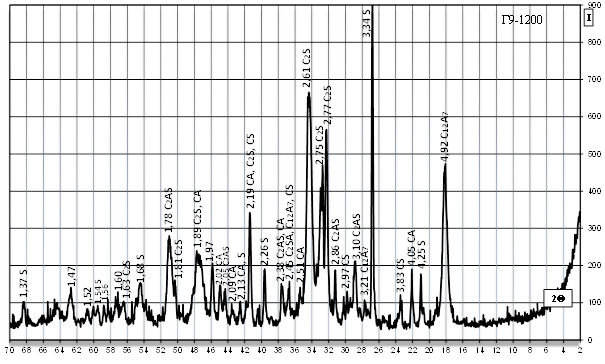

The object of research was silicate systems based on CaO–SiO2–AL2O3 oxides for the production of white cement under the condition of reducing the maximum firing temperature and energy intensity of the products. A complex of raw materials of different genesis was chosen for the study – chalk, pyloquartz, aluminum hydroxide. The criteria for the selection of raw materials were increased reactivity during firing and minimization of the content of colored oxides. During the research, methods of physico-chemical analysis of silicates and standardized testing of properties were comprehensively applied. Determination of the rational compositions of the raw material mixture was carried out using the created computer program «RomanCem». Based on the analysis of the calculation results, a significant value of the quantitative ratio of aluminum-silica-containing components Ca/Cp was determined. It was established that in the interval of the quantitative ratio Ca/Cp from 0.4 to 0.6, the silica modulus of the binder changes in an inversely proportional dependence within n=3.8–2.5 at a low content of colored iron oxides at the level of C=0.14–0.17 %. The compositions of the raw material mixture based on chalk with the use of an aluminum-silica-containing complex of aluminum hydroxide-powder quartz were determined, which allow, at the maximum firing temperature of 1100–1200 °C, to obtain a mineral binder that exceeds natural or Roman cement in terms of strength (21–27 MPa versus 10–15 MPa) and whiteness (80–85 % versus 55–60 %). Peculiarities of phase transformations in the material during low-temperature firing as a factor of structure and properties are noted. The development and practical use of white cement, obtained by reducing the maximum firing temperature and, accordingly, specific fuel consumption, reveals additional reserves for the production of mineral binders, contributes to the comprehensive solution of issues of resource conservation and production technology of silicate building materials.

References

- Duda, W. H. (1988). Cement Data Book. Vol. 3: Raw Material for Cement Production. French & European Pubns, 188.

- Ghosh, S. N. (2003). Advances in Cement Technology: Chemistry, Manufacture and Testing. Taylor & Francis, 828.

- Chatterjee, A. K. (2018). Cement Production Technology. Principles and Practice. CRC Press, 439.

- Moresová, K., Škvára, F. (2001). White cement – Properties, manufacture, prospects. Ceramics Silikaty, 45 (4), 158–163.

- Dorohan, N. O., Sviderskyy, V. A., Cherniak, L. P. (2018). Bilyi portlandtsement. Kyiv: KPI im. Ihoria Sikorskoho, vyd-vo «Politekhnika», 204.

- Varas, M. J., Alvarez de Buergo, M., Fort, R. (2005). Natural cement as the precursor of Portland cement: Methodology for its identification. Cement and Concrete Research, 35 (11), 2055–2065. doi: https://doi.org/10.1016/j.cemconres.2004.10.045

- Miras, T., Markopoulos, E. G. (2007). Natural cements for constructions applications. XXVII Reunion de la sociedad espaniol de mineralogia.

- ASTM C10 / C10M-14. Standard Specification for Natural Cement – ASTM International (2014). West Conshohocken.

- Hughes, D. C., Jaglin, D., Kozłowski, R., Mucha, D. (2009). Roman cements – Belite cements calcined at low temperature. Cement and Concrete Research, 39 (2), 77–89. doi: https://doi.org/10.1016/j.cemconres.2008.11.010

- Shelonh, H., Sanytskyi, M. A., Kropyvnytska, T. P., Kotiv, R. M. (2012). Romantsement – v’iazhuche dlia oporiadzhuvalnykh robit v budivnytstvi. Stroytelnie materyali y yzdelyia, 1 (72), 7–12.

- Sviderskyy, V. A., Cherniak, L. P., Dorogan, N. O., Nudchenko, L. A. (2017). Pіdvishchennia pokaznikіv vlastivostei v’iazhuchogo materіalu tipu romantcementu. Stroitelnye materialy i izdeliia, 5-6 (96), 20–22.

- Berezhnoi, A. S., Pytak, Ya. M., Ponomarenko, O. D., Sobol, N. P. (1992). Fizyko-khimichni systemy tuhoplavkykh, nemetalichnykh i sylikatnykh materialiv. Kyiv: NMK VO, 172.

- Sviderskyy, V. A., Cherniak, L. P., Sanhinova, O. V., Dorohan, N. O., Tsybenko, M. Yu. (2017). Prohramne zabezpechennia tekhnolohii nyzkotempe-raturnykh viazhuchykh materialiv. Budivelni materialy ta vyroby, 1-2 (93), 22–24.

- DSTU B V.2.7-91-99. V’iazhuchi mineralni. Klasyfikatsiia. Vved. 01.03.1999 (1999). Kyiv: Derzhbud Ukrainy, 26.

- DSTU B V.2.7-257:2011. Portlandtsementy bili. Tekhnichni umovy. Vved. 01.12.2012 (2012). Kyiv: Minrehion Ukrainy, 20.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Nataliia Dorogan, Lev Chernyak, Victoria Pakhomova, Oleg Shnyruk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.