Comparative assessment of the surface properties of Ukrainian ash microspheres

DOI:

https://doi.org/10.15587/2706-5448.2023.291967Keywords:

aluminosilicate (ash) microspheres, chemical and mineralogical composition, structure-forming bonds, IR spectroscopy, wettability, specific surface areaAbstract

The object of research is ash microspheres from the burning of hard coal in Donetsk, Lviv-Volyn (Ukraine) and foreign (South Africa) basins, power plants of various regions. The chemical and mineralogical composition of Ukrainian ash microspheres was analyzed in comparison with foreign counterparts (South Africa, Great Britain, etc.), other types of microspheres (glass, ceramic) and expanded perlite. The advantages of aluminosilicate microspheres of technogenic origin (ASM) over other lightweight fillers are noted.

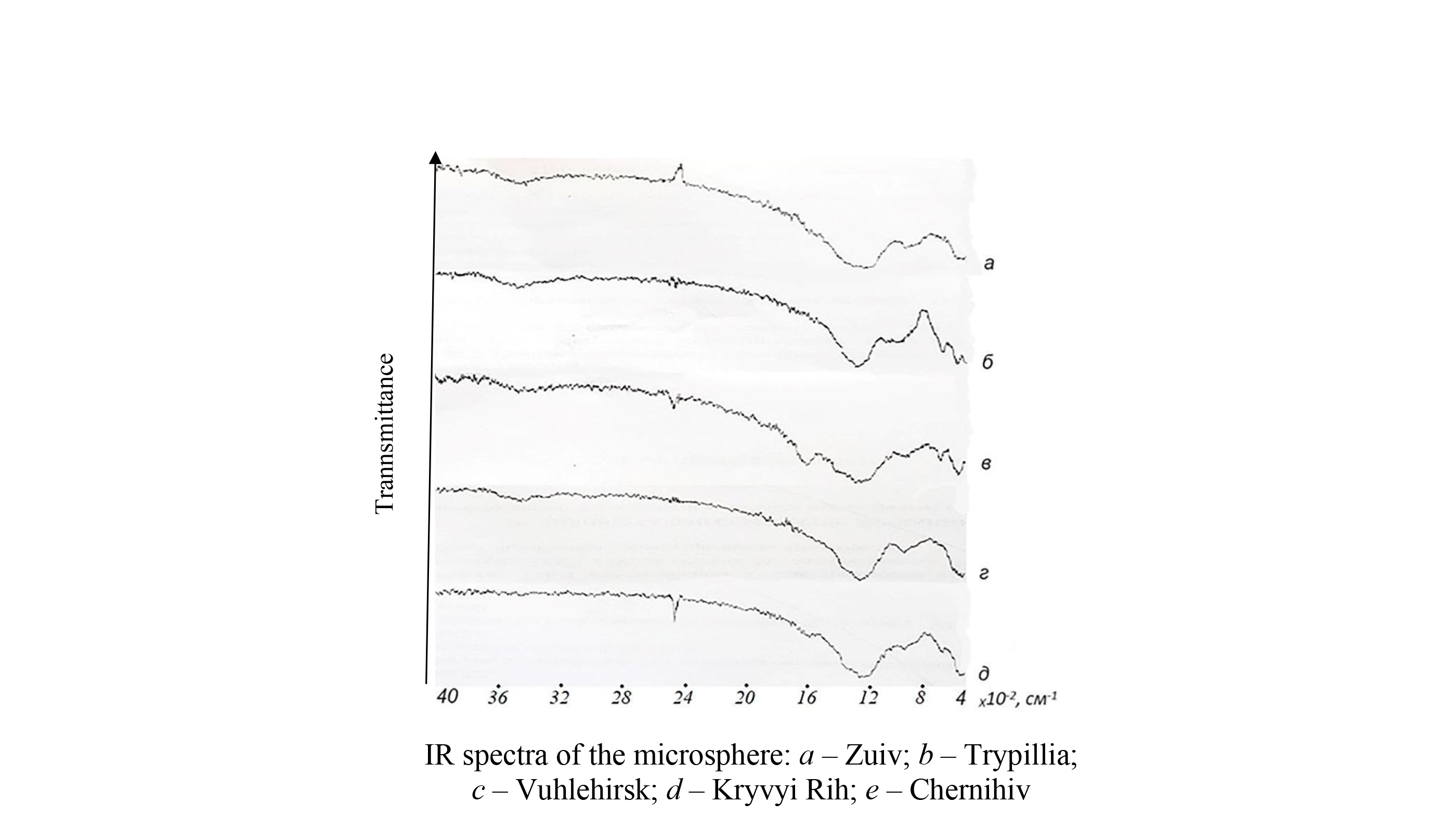

One of the most problematic areas is the lack of an objective comparative assessment of Ukrainian ash microspheres in terms of the influence of the structure-forming bonds Si–O, Si–O–Si and Si–O–Al on the physicochemical properties and energy and reactivity of their surface. It was established that the SiO2/Al2O3 ratio in their composition is within 1.46–1.87 against 1.53–1.64 in South African ASM and 4.81–5.61 in swollen pearlites, which ensures the content of crystalline phases (mullite, quartz) from 36 wt. % in Trypil microspheres to 53 wt. % in Kurakhove microspheres. The latter have a minimal content of Si–O–Si bonds (the I0/I ratio in the 1029 cm–1 band is 1.25 versus 6.71 in Burstyn ASM).

The revealed features of changes in the chemical and mineralogical composition of microspheres, as well as structure-forming bonds, are fully correlated with the content of adsorbed water and OH and CH groups in the surface layer of the latter and, as a result, the energy state and reactivity of ASM. A quantitative assessment of their wettability with water (0.32–0.106) and under the condition of tgδ (0.196–0.4490) is given. The availability of such information makes it possible to clearly classify Ukrainian ash microspheres according to the degree of efficiency of use, taking into account their advantages in the composition of composite materials on various types of binders and to assess the presence of interchangeability in the context of a special situation in Ukraine.

References

- Antonenko, M. S. (2020). Tekhnolohii zmenshennia vplyvu zolovidvaliv pidpryiemstv teploenerhetyky na navkolyshnie seredovyshche. Sumy, 43. Available at: https://core.ac.uk/download/pdf/339161984.pdf

- Kizilshtein, L. Ia., Dubov, N. V., Shpitcgluz, A. L. (1995). Komponenty zol i shlakov TES. Moscow: Energoatomizdat, 176.

- Drozhzhin, V. S., Shpirt, M. Ya., Danilin, L. D., Kuvaev, M. D., Pikulin, I. V., Potemkin, G. A., Redyushev, S. A. (2008). Formation processes and main properties of hollow aluminosilicate microspheres in fly ash from thermal power stations. Solid Fuel Chemistry, 42 (2), 107–119. doi: https://doi.org/10.3103/s0361521908020110

- Jaworek, A., Sobczyk, A. T., Czech, T., Marchewicz, A., Krupa, A. (2023). Recovery of cenospheres from solid waste produced by coal-fired power plants. Cleaner Waste Systems, 6, 100109. doi: https://doi.org/10.1016/j.clwas.2023.100109

- Biletskyi, V. S. (Ed.) (2004). Mala hirnycha entsyklopediia. Vol. 2. Donetsk: Donbas, 640.

- Ehorov-Tysmenko, Yu. K. (2005). Krystallohrafyia y krystallokhymyia. Moscow, 589.

- Sviderskyi, V., Demchenko, V. (2007). Chemical composition and dispersion of domesticash microspheres. Tovary i rynky, 1, 69–79. Available at: http://nbuv.gov.ua/UJRN/tovary_2017_1_9

- Kholdaeva, M. І. (2010). Struktura ta vlastivostі polіstirolbetonu z mіkrosfernim napovniuvachem. Odesa, 172.

- Demchenko, V., Simyachko, O., Svidersky, V. (2017). Research of mineralogical composition, structure and properties of the surface of Ukrainian ash microspheres. Technology Audit and Production Reserves, 6 (1 (38)), 28–34. doi: https://doi.org/10.15587/2312-8372.2017.118958

- Kazimirenko, Iu. A., Lebedeva, N. Iu., Karpechenko, A. A., Zhdanov, A. A. (2013). Formirovanie elektrodugovykh pokrytii s povyshennoi prochnostiu, dempfiruiushchei sposobnostiu i koeffitcientom pogloshcheniia izluchenii. Naukovі notatki, 41 (1), 117–121.

- Poplavko, Yu. M. (2017). Fizyka tverdoho tila. Vol. 1: Struktura, kvazichastynky, metaly, mahnetyky. Kyiv: KPI im. Ihoria Sikorskoho, Vyd-vo «Politekhnika», 415.

- Shchukina, L. P., Halushka, Ya. O., Yashchenko, L. O., Lihezin, S. L. (2021). Forecast evaluation of heat protection and mechanical properties of insulating construction ceramic materials. Bulletin of the National Technical University «KhPI». Series: Chemistry, Chemical Technology and Ecology, 1 (5), 68–74.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Taras Berehovyi, Valentin Sviderskyi

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.