Force effect of a circular rotating magnetic field of a cylindrical electric inductor on a ferromagnetic particle in process reactors

DOI:

https://doi.org/10.15587/2706-5448.2023.293005Keywords:

electromagnetic mills, circular field, cylindrical magnetic field inductor, ferromagnetic particles, magnetization, magnetic forcesAbstract

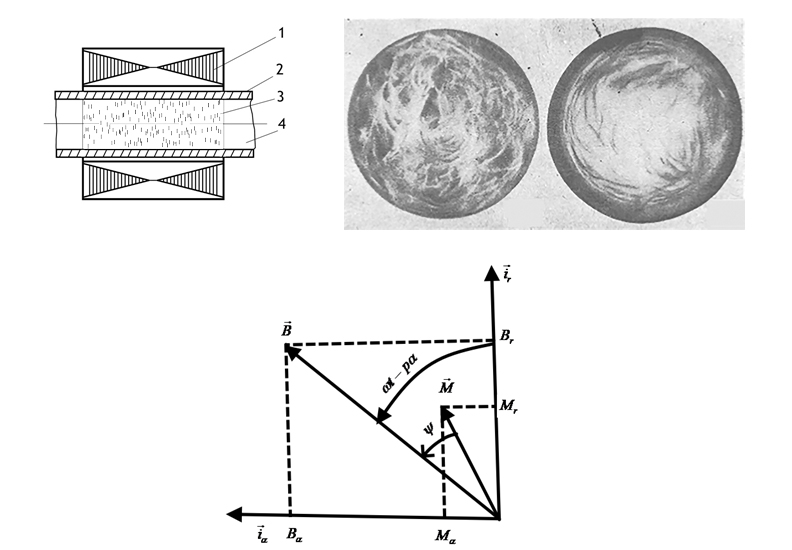

The object of research is the force effect of a circular magnetic field of cylindrical inductors with alternating current windings on the actuator element of technological reactors – a ferromagnetic particle. Technologies using a rotating magnetic field and ferromagnetic particles (RMF and FP) are increasingly used in industry, in devices for fine and ultra-fine grinding, mixing and activation, in the construction and chemical industries, in energy-saving and environmental systems.

In previous studies, the authors proposed a method for calculating the force effect on ferromagnetic particles (FP) of an elliptical rotating magnetic field (RMF) of an external cylindrical inductor with a symmetrical alternating current winding. In this work, based on this technique, formulas for the force effect on the FP of the fundamental harmonic of RMF of cylindrical inductors with different numbers of pole pairs are derived and analyzed.

It is shown that for a hard magnetic and saturated magnetically soft (soft-magnetic) particle in a circular field of a cylindrical inductor with the number of pole pairs greater than one, the magnitude of the magnetic displacement force does not depend on the orientation of the magnetic moment of the ferromagnetic particle, and the direction of action of this force is determined by the angle between the circular field induction vector and the magnetic moment of the particle. While maintaining the similarity of the inductors and the equality of the amplitude of the magnetic induction on the surface of the inductor bore, the magnetic displacement force does not retain the similarity, in particular, while maintaining the values of the magnetic moment of the particle, this force is inversely proportional to the radius of the bore of the cylindrical inductor.

Examples are given of the use of formulas for calculating the ratio of displacement forces to the weight of a particle and the calculation of forces for an unsaturated soft-magnetic particle, where, due to the dependence of the magnetic moment on the field strength, the calculation formulas are modified and take on a slightly different form than the formulas for a particle with a constant modulus magnetic moment.

The research results will be useful for engineers and researchers involved in the research, development, design and operation of reactors with RMF and FP technologies.

References

- Moerland, C. P., van IJzendoorn, L. J., Prins, M. W. J. (2019). Rotating magnetic particles for lab-on-chip applications – a comprehensive review. Lab on a Chip, 19 (6), 919–933. doi: https://doi.org/10.1039/c8lc01323c

- Logvinenko, D. D., Shelyakov, O. P., Pol’shchikov, G. A. (1974). Determination of the main parameters of vortex bed apparatus. Chemical and Petroleum Engineering, 10 (1), 15–17. doi: https://doi.org/10.1007/bf01146127

- GlobeCore Transformer Oil Purification Equipment, Bitumen Equipment. Available at: https://globecore.com/ Last accessed: 22.09.2023

- Oberemok, V. M. (2010). Elektromahnitni aparaty z feromahnitnymy robochymy elementamy. Osoblyvosti zastosuvannia. Poltava: RVV PUSKU, 201. Available at: http://dspace.puet.edu.ua/handle/123456789/6536

- Ogonowski, S. (2021). On-Line Optimization of Energy Consumption in Electromagnetic Mill Installation. Energies, 14 (9), 2380. doi: https://doi.org/10.3390/en14092380

- May, F. (2017). Electromagnetic Intensification of Heavy Metal Removal and Wastewater Decontamination. Water Today, 32–38.

- Styła, S. (2017). A New Grinding Technology Using an Electromagnetic Mill – Testing the Efficiency of the Process Econtechmod. An International Quarterly Journal, 6 (1), 81–88.

- Litinas, A., Geivanidis, S., Faliakis, A., Courouclis, Y., Samaras, Z., Keder, A. et al. (2020). Biodiesel production from high FFA feedstocks with a novel chemical multifunctional process intensifier. Biofuel Research Journal, 7 (2), 1170–1177. doi: https://doi.org/10.18331/brj2020.7.2.5

- Kazak, O., Halbedel, B. (2023). Correlation of the Vector Gradient of a Magnetic Field with the Kinetic Energy of Hard Magnetic Milling Beads in Electromechanical Mills. Chemie Ingenieur Technik, 95 (10), 1615–1622. doi: https://doi.org/10.1002/cite.202200183

- Polshchikov, G. A., Logvinenko, D. D., Zhukov, P. B. (1975). Nekotorye voprosy rascheta i proektirovaniia apparatov s vikhrevym sloem. NIIKhIMMASh. Oborudovanie s ispolzovaniem razlichnykh metodov intensifikatcii protcessov. Moscow, 71, 128–141.

- Makarchuk, O., Calus, D., Moroz, V. (2021). Mathematical model to calculate the trajectories of electromagnetic mill operating elements. Tekhnichna Elektrodynamika, 2021 (2), 26–34. doi: https://doi.org/10.15407/techned2021.02.026

- Całus, D. (2023). Experimental Research into the Efficiency of an Electromagnetic Mill. Applied Sciences, 13 (15), 8717. doi: https://doi.org/10.3390/app13158717

- Polshchikov, G. A., Zhukov, P. B. (1975). O dvizhenii magnitnoi chastitcy v apparate s vikhrevym sloem. Khimicheskoe mashinostroenie (respublikanskii mezhvedomstvennyi nauchno-tekhnicheskii sbornik). Kyiv: Tekhnika, 22.

- Keskiula, V. F., Ristkhein, E. M. (1965). Vozmozhnye sistemy magnitoprovoda i obmotok induktcionnykh vrashchatelei. Trudy Tallinskogo politekhnicheskogo instituta. Seriia A., 231, 69–85.

- Polivanov, K. M., Levitan, S. A. (1966). Ob odnoi zadache rascheta vrashchaiushchegosia magnitnogo polia. Elektrotekhnika, 12, 5–7.

- Levitan, S. A., Syrkin, V. G., Tolmasskii, I. S. (1969). Primenenie vrashchaiushchegosia magnitnogo polia dlia ulavlivaniia vysokodispersnogo ferromagnitnogo poroshka. Elektronnaia obrabotka materialov, 2 (26), 55–59.

- Koniaev, A. Iu., Bagin, D. N. (2021). Modelirovanie i issledovanie elektromagnitnykh smesitelei poroshkovykh materialov. Vestnik PNIPU. Elektrotekhnika, informatcionnye tekhnologii, sistemy upravleniia, 38, 129–147.

- Polivanov, K. M. (1969). Teoreticheskie osnovy elektrotekhniki, ch. 3. Moscow, 352.

- Polivanov, K. M. (1957). Ferromagnetiki. Moscow, Leningrad: Gosenergoizdat, 256.

- Logvinenko, D. D., Sheliakov, O. P. (1976). Intensifikatciia tekhnologicheskikh protcessov v apparatakh s vikhrevym sloem. Kyiv: Tekhnіka, 144.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Henrikh Polshchikov, Pavlo Zhukov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.