Characteristics of black liquor after alkaline delignification of paulownia wood

DOI:

https://doi.org/10.15587/2706-5448.2023.293363Keywords:

paulownia, alkaline pulping, black liquor, pH, total and active alkalinity, dry solids, organic and mineral compoundsAbstract

The object of research is the black liquor of the alkaline pulping sample Paulownia Clone in Vitro 112® with active alkali consumption of 14, 18 and 22 % in Na2O units from the mass of completely dry raw materials.

The problem solved in the work is related to the formation of waste in the form of black liquor during pulp production. It is noted that as a result of the production of 1 ton of cellulose, up to 7 tons of black liquor is formed.

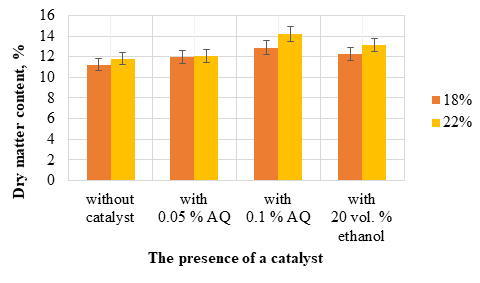

In the course of the work, an analysis of the total titrated and active alkalinity in the white and black liquor after cooking paulownia wood was carried out, and the pH value was determined. The dependence of the content of dry substances in black liquor on the consumption of active alkali, the duration of cooking, the presence of a catalyst, and the final temperature of the delignification process is given. The amount of organic and mineral components of dry substances of black liquor per 1 ton of air-dry fibrous semi-finished products was calculated.

It was established that with an increase in temperature by 20 °C (from 150 to 170 °C) and a duration of approximately 1.5 times (from 60 to 90 min and from 90 to 150 min), with the same consumption of active alkali and the use of a catalyst in the conditions after sodium pulping, the content of dry substances in the black liquor increases by 1.5–3 %. This regularity is explained by the transition into the solution of a greater number of dissolution products of lignin, hemicelluloses, and mineral substances.

Estimated values for the content of mineral and organic substances in black liquor after cooking paulownia wood for a duration of 150 min and a final temperature of 170 °C at different consumptions of active alkali and the use of catalysts in the form of anthraquinone and ethyl alcohol are within the range of 1024-1518 kg per 1 ton dry pulps of normal yield and can be used in practice. The obtained results can be used to form an assessment of the black liquor as an additional resource potential for the economy of production.

References

- Cheropkina, R. I., Trembus, I. V., Deikun, I. M., Barbash, V. A. (2021). Tekhnolohiia nederevnykh voloknystykh napivfabrykativ. Kyiv: KPI im. Ihoria Sikorskoho, 231.

- Kuparinen, K., Vakkilainen, E., Tynjälä, T. (2019). Biomass-based carbon capture and utilization in kraft pulp mills. Mitigation and Adaptation Strategies for Global Change, 24 (7), 1213–1230. doi: https://doi.org/10.1007/s11027-018-9833-9

- Black Liquor Gasification. Summary and Conclusions from the IEA Bioenergy ExCo54 Workshop (2007). IEA Bioenergy: ExCo:2007:03. Whakarewarewa, Rotorua, 1–12.

- Prymakov, S. F., Antonenko, L. P., Barbash, V. A., Deikun, I. M., Cheropkina, R. I. (2003). Metodychni vkazivky do vykonannia laboratornykh robit i kontrolnykh zavdan z dystsypliny – Tekhnolohiia tseliulozy dlia studentiv spetsializatsii 7.091611. 02 – Khimichna tekhnolohiia tseliulozno-paperovoho vyrobnytstva. Kyiv: KPI, 71.

- Fakhrai, R. (2002). Black Liquor Combustion in Kraft Recovery Boilers-Numerical Modelling. Stockholm: Royal Institute of Technology, 86.

- Introduction to Liquor of Paper Pulping. Available at: https://www.paperpulpingmachine.com/introduction-to-liquor-of-paper-pulping/

- Black Liquor. Encyclopedia, Science News & Research Reviews. Available at: https://academic-accelerator.com/encyclopedia/black-liquor

- Hubbe, M., Alén, R., Paleologou, M., Kannangara, M., Kihlman, J. (2019). Lignin recovery from spent alkaline pulping liquors using acidification, membrane separation, and related processing steps: A review. BioResources, 14 (1), 2300–2351. doi: https://doi.org/10.15376/biores.14.1.2300-2351

- Larson, E. D., Consonni, S., Katofsky, R. E. (2003). A Cost-Benefit Assessment of Biomass Gasification Power Generation in the Pulp and Paper Industry: FINAL REPORT. Princeton: Princeton University, 191.

- Black liquor. Available at: https://www.ctc-n.org/technologies/black-liquor

- Råberg, M. (2007). Black liquor gasification – Experimental stability studies of smelt components and refractory ligning. Umeå: Umeå University, 48.

- Global investment in clean energy is on course to rise to USD 1.7 trillion in 2023. Available at: https://www.fananews.com/language/en/global-investment-in-clean-energy-is-on-course-to-rise-to-usd-1-7-trillion-in-2023/

- Pola, L., Collado, S., Oulego, P., Díaz, M. (2022). Kraft black liquor as a renewable source of value-added chemicals. Chemical Engineering Journal, 448, 137728. doi: https://doi.org/10.1016/j.cej.2022.137728

- Kempkens, J. (2020). Black Liquor – New Material from Lignin. Available at: https://isola.design/Designer-Projects-Black-Liquor--New-Materials-From-Lignin

- TAPPI/ANSI T 412. Moisture in pulp, paper and paperboard (2022). Atlanta: TAPPI Press.

- TAPPI T 222. Acid-insoluble lignin in wood and pulp (2021). Atlanta: TAPPI Press.

- TAPPI T-650. Solids content of black liquor (2021). Atlanta: TAPPI Press.

- TAPPI T 625. Analysis of soda and sulfate black liquor (2014). Atlanta: TAPPI Press.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Anna Denysenko, Romaniia Cheropkina

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.