Аналіз досвіду оптимізації роботи автоматизованої виробничої лінії зі згортання картонних коробок

DOI:

https://doi.org/10.15587/2706-5448.2024.297399Ключові слова:

автоматизована система, технологічний процес, структурна схема, програмований логічний контролер, панель-контролерАнотація

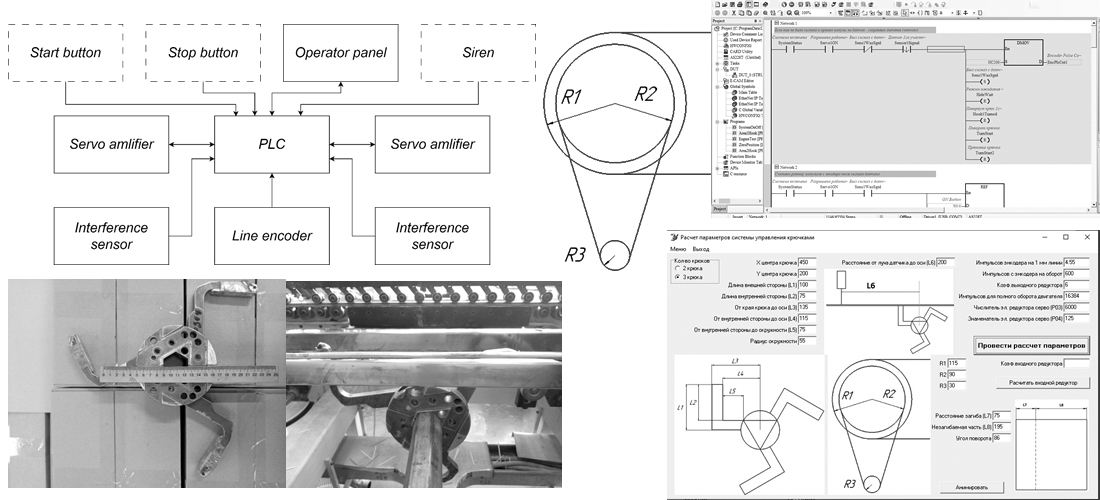

Об’єктом дослідження є автоматизована система керування механізмами загину фальцювально-склеюючої лінії для пакувальної продукції з картону. В роботі проведено визначення шляхів оптимізації та розробка автоматизованої системи керування механізмами загину фальцювально-склеюючої лінії, що дає можливість згортання різних конструкцій та типорозмірів картонних коробок з використанням сучасних засобів автоматизації на основі програмованих логічних контролерів.

Була запропонована математична модель для опису операцій на фальцювально-склеюючій лінії. На основі моделі було розроблено методику розрахунку параметрів автоматизованої системи керування виробничою лінією згортання коробок в залежності від технічних параметрів лінії та параметрів коробок, які підлягають згинанню. Це дозволить обирати оптимальні технологічні режими процесу виробництва та одержувати високі параметри якості пакувальної продукції з картону. Для перевірки математичної моделі виробничої лінії було розроблено програмне забезпечення у середовищі розробки Delphi, яке було застосоване з розробленою автоматизованою системою керування виробничим процесом на базі програмованого логічного контролера (ПЛК) та панелі оператора. Це дало ряд результатів, зокрема, керування швидкістю загину гачків пропорційно швидкості руху лінії. А також надало можливість збільшити швидкість лінії та, відповідно, продуктивність виробництва. Реалізовано можливість зміни взаєморозташування елементів системи, що надало змогу зменшити відстань між заготовками та збільшити заповнюваність стрічки лінії на 30 %.

Отримані результати досліджень впроваджені на виробничому підприємстві типографічної продукції «Дінас» (Запоріжжя, Україна), що сприяло вдосконаленню та оптимізації виробничих процесів. Проведення подальших досліджень наддасть можливість розширити запропоновану методику для застосування на усіх типах фальцювально-склеюючих ліній

Посилання

- Twede, D., Selke, S. E., Kamdem, D. P., Shires, D. (2014). Cartons, crates and corrugated board: handbook of paper and wood packaging technology. DEStech Publications, Inc. Available at: https://destechpub.com/wp-content/uploads/2015/01/Cartons-Crates-and-Corrugated-Board-2nd-Ed-preview.pdf

- Freddi, A., Salmon, M. (2019). Design of a Packaging Machine: General Description and Conceptualization. Design Principles and Methodologies. Springer Tracts in Mechanical Engineering. Cham: Springer, 205–237. doi: https://doi.org/10.1007/978-3-319-95342-7_9

- Zhang, X. (2022). The Application of Folding Structure in Paper Packaging Design. Proceedings of the 2021 Conference on Art and Design: Inheritance and Innovation (ADII 2021). Atlantis Press, 281–285. doi: https://doi.org/10.2991/assehr.k.220205.046

- Shan, S., Ma, Y., Tang, C., Chen, X. (2018). Folding cartons: Interactive manipulation of cartons from 2D layouts. Computer Aided Geometric Design, 62, 228–238. doi: https://doi.org/10.1016/j.cagd.2018.03.018

- Zhu, L., Xie, B., Zhang, Y. J., Yu, L.-F. (2019). Cartonist: Automatic Synthesis and Interactive Exploration of Nonstandard Carton Design. Computer-Aided Design, 114, 215–223. doi: https://doi.org/10.1016/j.cad.2019.04.007

- Garbowski, T., Gajewski, T., Knitter-Piątkowska, A. (2022). Influence of Analog and Digital Crease Lines on Mechanical Parameters of Corrugated Board and Packaging. Sensors, 22 (13), 4800. doi: https://doi.org/10.3390/s22134800

- Srivastava, A., Kumar, V., Singh, A. K. (2018). Computerized and electronic controls in food packaging. Journal of Applied Packaging Research, 10 (1), 3.

- Xiao, L., Qu, B., Shi, E. (2021). Design of Automatic Packing System in Workshop Based on Programmable Logic Controller (PLC). 2021 4th International Conference on Information Systems and Computer Aided Education, 2268–2272. doi: https://doi.org/10.1145/3482632.3484142

- Hambir, P., Joshi, N., Karande, P., Kolhe, A., Karande, P., Kolhe, A. (2019). Automatic weighing and packaging machine. International Research Journal of Engineering and Technology, 7 (5), 2129–2138.

- Rehei, I. I., Behen, P. I. (2023). Blanks extraction and feeding devices of semi-finished cardboard in the technological section of packaging equipment: analysis, perspectives and ways of improvement. Printing and Publishing, 1 (85), 164–173. doi: https://doi.org/10.32403/0554-4866-2023-1-85-164-173

- Wang, D., Ge, C. (2016). Opening of Perforated Folding Cartons: From the Field to Testing. Packaging Technology and Science, 30 (8), 411–425. doi: https://doi.org/10.1002/pts.2266

- Monir, M., Nasser, M., AbdelGhaffar, E., Omar, M., Sabry, Y., Mandour, M. (2022). PLC Based Automatic Packaging System. The International Undergraduate Research Conference, 6 (6), 1–5.

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Oleksandr Malyi, Nataliia Furmanova, Vadym Onyshchenko, Iryna Pospeieva, Pavlo Kostianoi

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.