Дослідження особливостей методів сталого та звичайного реверс-інжинірингу деталей складних форм

DOI:

https://doi.org/10.15587/2706-5448.2024.297768Ключові слова:

сталий реверс-інжиніринг, реверс-інжиніринг, 3D-сканування, аналітичний еталон, деталі складної формиАнотація

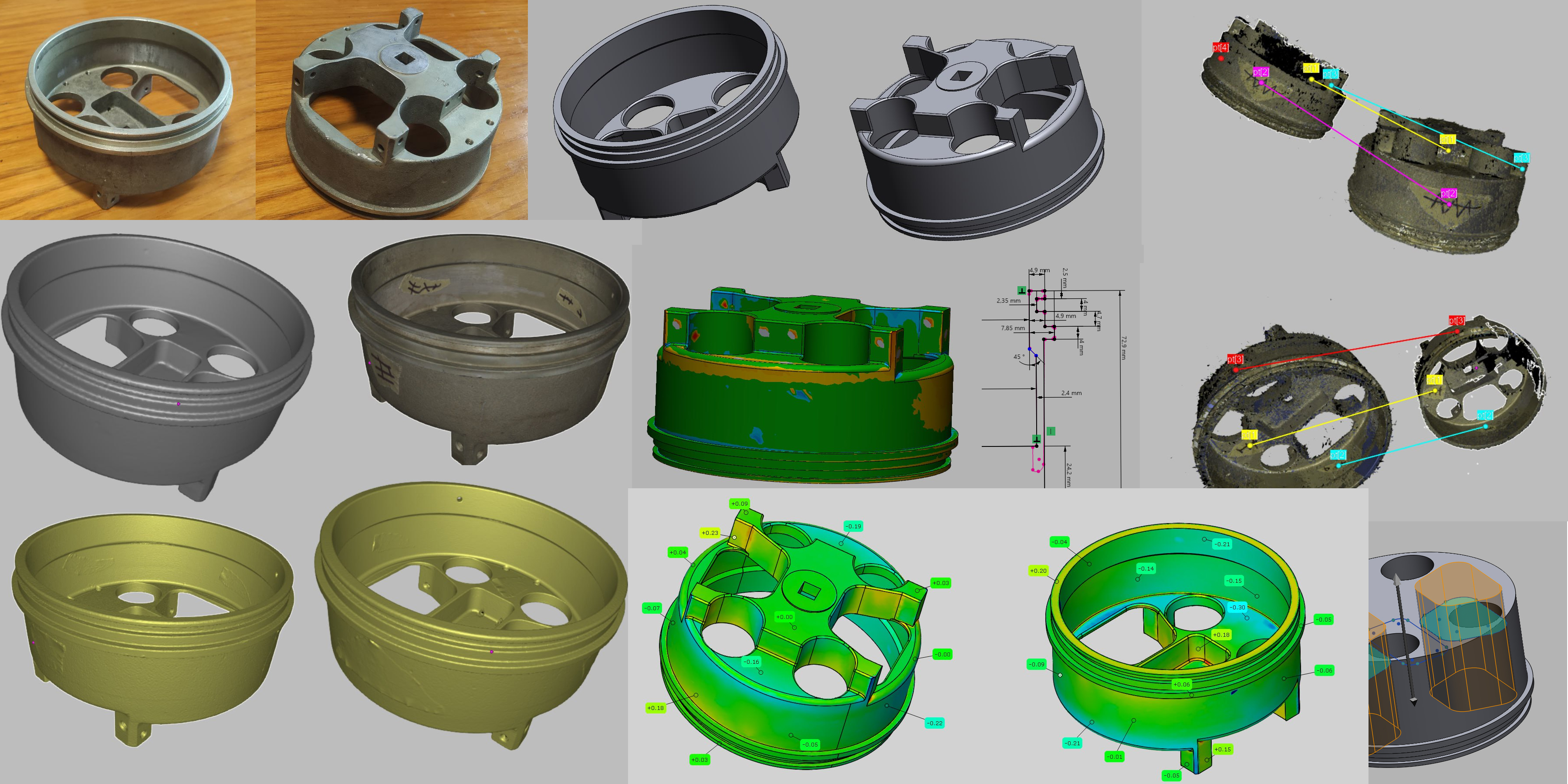

Предметом вивчення є сталий реверс-інжиніринг та звичайний реверс-інжиніринг зразків авіаційної техніки (АТ). Об’єктом дослідження є геометрична точність видобутого портрету деталі складної форми в порівнянні з побудованим аналітичним еталоном (АЕ). Робота направлена на дослідження методів сталого реверс-інжинірингу та звичайного реверс-інжинірингу на прикладі оцифровування корпусу рулевої машини АТ, обраної як деталь складної форми. Для цього було створено портрет файлу формату «*.stl» і АЕ та порівняно їх шляхом виконання операції контролю з визначенням витраченого часу. Проведено конструктивно-технологічний аналіз корпусу рулевої машини АТ, який показав, що корпус має наскрізні отвори різних діаметрів (від 10 до 41,6 мм) і форм (квадратні, трапецієвидні, круглі); тонкі стінки між отворами (до 1,6 мм); прямі кути та радіуси закруглення в них (до 1–4 мм); товщину стінок корпусу 2,4 мм тощо. Підібрано 3D-сканер – ARTEC SPACE SPIDER (Luxembourg) та виконано сканування. Згідно аналізу дослідних методів реверс-інжинірингу встановлено, що використання сталого та звичайного реверс-інжинірингів дозволяє в першому випадку швидко виготовити деталь за 3D-друком або фрезеруванням на станках з ЧПК, а в другому – створити її АЕ з забезпеченням заданої геометричної точності. Різниця в часі між сталим та звичайним реверс-інжинірингом становила 8 годин на користь першого. Контроль ідеального портрету за АЕ корпусу рулевої машини АТ показав максимальні відхилення від –0,30 мм до +0,23 мм і мінімальні – від –0,04 мм до +0,08 мм. Найменші показники спостерігалися на вертикальних і горизонтальних площинах, а найбільші – в містах нахилів площин, кутів і маленьких радіусів. Це дало змогу встановити, що існуючі можливості програмного забезпечення Geomagic Design X щодо корекції отриманого портрету файлу формату «*.stl» на даний час не гарантує забезпечення вимог геометричної точності (до ±0,5 мм) на виготовлення дослідної деталі складної форми – корпусу рулевої машини АТ 3D-друком. Отриманий ідеальний портрет можна використовувати для виготовлення деталі фрезеруванням на станках з ЧПК з урахуванням відхилень на етапі формування моделі процесів, що може стати темою наступних досліджень.

Спонсор дослідження

- Presentation of research in the form of publication through financial support in the form of a grant «Technological systems of production and restorative repair of objects and components of military equipment, provided by foreign partners or captured, to solve the problems of import substitution and strengthening the defense capability of Ukraine» from the publisher National Aerospace University «Kharkiv Aviation Institute» (Kharkiv, Ukraine).

Посилання

- Stojkic, Z., Culjak, E., Saravanja, L. (2020). 3D Measurement – Comparison of CMM and 3D Scanner. Proceedings of the 31st International DAAAM Symposium 2020. Vienna: DAAAM International, 780–787. doi: https://doi.org/10.2507/31st.daaam.proceedings.108

- Bychkov, I., Seleznova, A., Maiorova, K., Vorobiov, I., Sikulskiy, V. (2022). Requirements development for the information support manufacturing of aerospace products to ensure their quality. Aerospace Technic and Technology, 4, 22–35. doi: https://doi.org/10.32620/aktt.2022.4.03

- Maiorova, K., Vorobiov, I., Boiko, M., Suponina, V., Komisarov, O. (2021). Implementation of reengineering technology to ensure the predefined geometric accuracy of a light aircraft keel. Eastern-European Journal of Enterprise Technologies, 6 (1 (114)), 6–12. doi: https://doi.org/10.15587/1729-4061.2021.246414

- Sikulskiy, V., Maiorova, K., Vorobiov, I., Boiko, M., Komisarov, O. (2022). Implementation of reengineering technology to reduce the terms of the technical preparation of manufacturing of aviation technology assemblies. Eastern-European Journal of Enterprise Technologies, 3 (1 (117)), 25–32. doi: https://doi.org/10.15587/1729-4061.2022.258550

- Bychkov, I. V., Plankoskiy, S. I., Romanov, A. A. (2014). The life cycle of the product and its information support. Avtomatizatciia i upravlenie tekhnologicheskimi protcessami i proizvodstvami, 18 (1 (62)), 149–155.

- Yurdakul, M., İç, Y. T., Celek, O. E. (2021). Design of the Assembly Systems for Airplane Structures. Design Engineering and Science, 521–541. doi: https://doi.org/10.1007/978-3-030-49232-8_18

- Durupt, A., Bricogne, M., Remy, S., Troussier, N., Rowson, H., Belkadi, F. (2018). An extended framework for knowledge modelling and reuse in reverse engineering projects. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 233 (5), 1377–1389. doi: https://doi.org/10.1177/0954405418789973

- Montlahuc, J., Ali Shah, G., Polette, A., Pernot, J.-P. (2019). As-scanned Point Clouds Generation for Virtual Reverse Engineer-ing of CAD Assembly Models. Computer-Aided Design and Applications, 16 (6), 1171–1182. doi: https://doi.org/10.14733/cadaps.2019.1171-1182

- Stark, R. (2022). Major Technology 6: Digital Mock-Up – DMU. Virtual Product Creation in Industry. Berlin, Heidelberg: Springer, 273–304. doi: https://doi.org/10.1007/978-3-662-64301-3_12

- Ivanov, V., Dimitrov, L., Ivanova, S., Volkova, M.; Karabegović, I. (Eds.) (2021). Reverse Engineering in the Remanufacturing: Metrology, Project Management, Redesign. New Technologies, Development and Application IV. NT 2021. Lecture Notes in Networks and Systems. Vol 233. Cham: Springer, 169–176. doi: https://doi.org/10.1007/978-3-030-75275-0_20

- Toche, B., Pellerin, R., Fortin, C., Huet, G. (2012). Set-Based Prototyping with Digital Mock-Up Technologies. IFIP Advances in Information and Communication Technology, 299–309. doi: https://doi.org/10.1007/978-3-642-35758-9_26

- Silva, J. V., Costa, S. L., Puga, H., Peixinho, N., Mendonça, J. P. (2013). Sustainable Reverse Engineering Methodology Assisting 3D Modeling of Footwear Safety Metallic Components. Vol. 2A: Advanced Manufacturing. San Diego. doi: https://doi.org/10.1115/imece2013-65190

- Saiga, K., Ullah, A. S., Kubo, A., Tashi. (2021). A Sustainable Reverse Engineering Process. Procedia CIRP, 98, 517–522. doi: https://doi.org/10.1016/j.procir.2021.01.144

- Technical specifications Artec Space Spider. Available at: https://www.artec3d.com/portable-3d-scanners/artec-spider#specifications

- Maiorova, K., Sikulskyi, V., Vorobiov, Iu., Kapinus, O., Knyr, A.; Nechyporuk, M., Pavlikov, V., Kritskiy, D. (Eds.) (2022). Study of a geometry accuracy of the bracket-type parts using reverse engineering and additive manufacturing technologies. Integrated Computer Technologies in Mechanical Engineering – 2022. ICTM 2022. Vol. 657. Kharkiv: National Aerospace University «Kharkiv Aviation Institute», 146–158. doi: https://doi.org/10.1007/978-3-031-36201-9_13

- Sikulskyi, V., Maiorova, K., Shypul, O., Nickichanov, V., Kapinus, O.; Nechyporuk, M., Pavlikov, V., Kritskiy, D. (Eds.) (2023). Algorithm for Selecting the Optimal Technology for Rapid Manufacturing and/or Repair of Parts. Integrated Computer Technologies in Mechanical Engineering – 2023. ICTM 2023. Kharkiv: National Aerospace University «Kharkiv Aviation Institute». (in print)

- Anwar, M. Y., Ikramullah, S., Mazhar, F. (2014). Reverse engineering in modeling of aircraft propeller blade – first step to product optimization. IIUM Engineering Journal, 15 (2). doi: https://doi.org/10.31436/iiumej.v15i2.497

- Guan, G., Wen-Wen, G. (2019). Reconstraction of propeller and complex ship hull surface based on reverse engineering. Journal of Marine Science and Technology, 27 (6), 498–504. doi: https://doi.org/10.6119/JMST.201912_27(6).0002

- Gómez, A., Olmos, V., Racero, J., Ríos, J., Arista, R., Mas, F. (2017). Development based on reverse engineering to manufacture aircraft custom-made parts. International Journal of Mechatronics and Manufacturing Systems, 10 (1), 40–58. doi: https://doi.org/10.1504/ijmms.2017.084406

- Dubovska, R., Jambor, J., Majerik, J. (2014). Implementation of CAD/CAM System CATIA V5 in Simulation of CNC Machining Process. Procedia Engineering, 69, 638–645. doi: https://doi.org/10.1016/j.proeng.2014.03.037

- Hoque, A. S. M., Halder, P. K., Parvez, M. S., Szecsi, T. (2013). Integrated manufacturing features and Design-for-manufacture guidelines for reducing product cost under CAD/CAM environment. Computers & Industrial Engineering, 66 (4), 988–1003. doi: https://doi.org/10.1016/j.cie.2013.08.016

##submission.downloads##

Опубліковано

Як цитувати

Номер

Розділ

Ліцензія

Авторське право (c) 2024 Kateryna Maiorova, Oleksandra Kapinus, Oleksandr Skyba

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.

Закріплення та умови передачі авторських прав (ідентифікація авторства) здійснюється у Ліцензійному договорі. Зокрема, автори залишають за собою право на авторство свого рукопису та передають журналу право першої публікації цієї роботи на умовах ліцензії Creative Commons CC BY. При цьому вони мають право укладати самостійно додаткові угоди, що стосуються неексклюзивного поширення роботи у тому вигляді, в якому вона була опублікована цим журналом, але за умови збереження посилання на першу публікацію статті в цьому журналі.