Analysis of combined processing method of phosphate minerals from the Kef Essenoun deposit

DOI:

https://doi.org/10.15587/2706-5448.2024.300739Keywords:

Beige phosphate, Black phosphate, phosphate characteristic, flotation method, calcination method, Tebessa, AlgeriaAbstract

Currently, the processing of beige and black phosphates only concerns the main sub-layers, while the other sub-layers (lower and upper for beige phosphate and the upper for black phosphate) are considered waste rock and stored near the complex. Therefore, the object of this research is the use of mixtures of three beige phosphate sub-layers and two black phosphate sub-layers as a feed fraction for the calcination and reverses flotation processes. This research work aims to characterise and treat two types of phosphate: one beige with the sub-layers (main, lower and upper) and the other black with the sub-layers (main and upper) in order to have better recovery of P2O5.

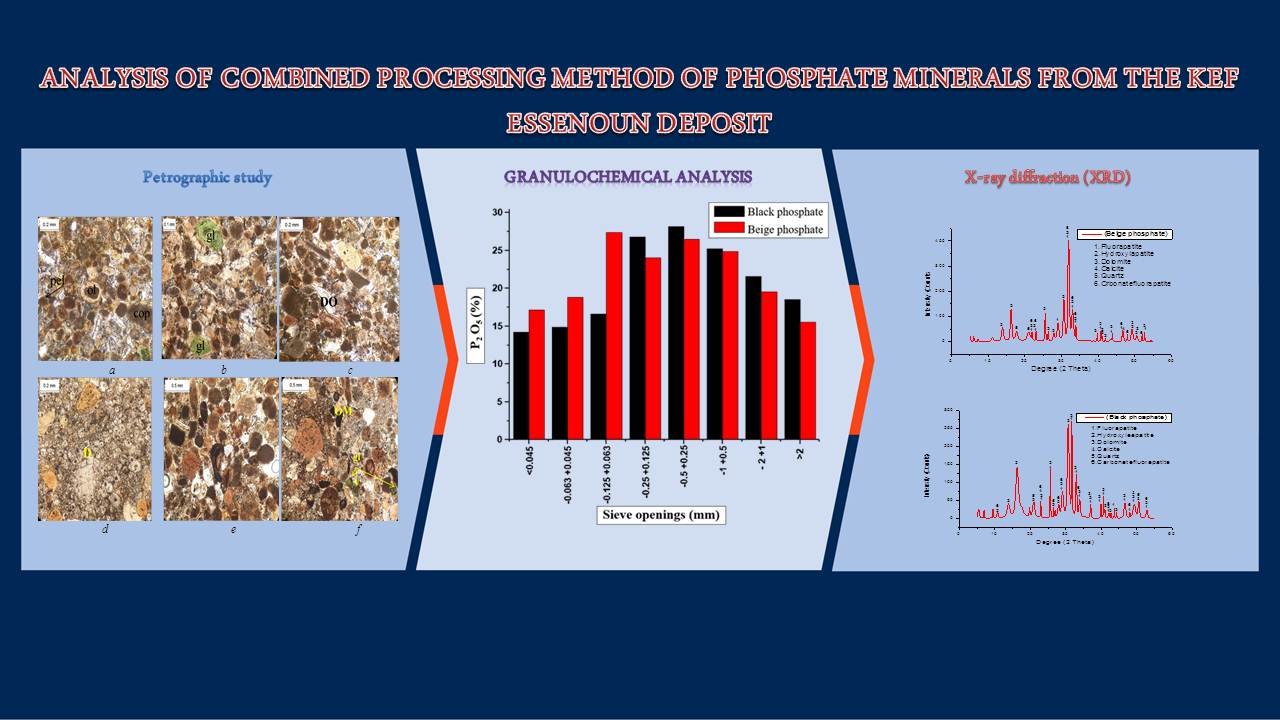

The working methodology consists of a series of sample preparation operations and characterization of the two types of beige and black phosphate. This characterization includes a petrographic study, a granulochemical analysis, an X-ray diffraction (XRD), a scanning electron microscopy/energy dispersive spectroscopy (SEM/EDS), and an atomic adsorption spectrophotometry (SAA), an auto analyzer (AA), a Bernard calcimeter. These analyzes allow on the one hand to identify the mineral phases in quantitative and qualitative manner, and on the other hand to choose the process for treating phosphates from the Kef Essenoun–Tebessa deposit.

The combined method of treatment by calcination followed by reverse flotation gave satisfactory results. The P2O5 content reaches 33.88 % for beige phosphate and 33.13 % for black phosphate.

The stored waste rock represents a problem for the company; this waste rock contains fairly high levels of phosphate. The treatment of the mixture of the main sub-layers with these waste rocks makes it possible to obtain a better recovery of P2O5, a better economic profitability of the Djebel Onk mining complex and an environmental impact in the region.

References

- Sherkuziev, D. (2021). Simple superphosphate by two-stage acid treatment of phosphate raw materials. IOP Conference Series: Earth and Environmental Science, 939 (1), 012057. doi: https://doi.org/10.1088/1755-1315/939/1/012057

- Aleksandrova, T., Elbendari, A. (2021). Increasing the efficiency of phosphate ore processing using flotation method. Journal of Mining Institute, 248, 260–271. doi: https://doi.org/10.31897/pmi.2021.2.10

- Ettoumi, M., Jouini, M., Neculita, C. M., Bouhlel, S., Coudert, L., Haouech, I., Benzaazoua, M. (2020). Characterization of Kef Shfeir phosphate sludge (Gafsa, Tunisia) and optimization of its dewatering. Journal of Environmental Management, 254, 109801. doi: https://doi.org/10.1016/j.jenvman.2019.109801

- Anouar, I., Jouraiphy, R., Essallaki, H., Mazouz, H., Yousfi, S., Boulif, R., Essaid, B. et al. (2021). Effect of phosphate quality on foam generation during the phosphoric acid production process. Physicochemical Problems of Mineral Processing, 57 (2), 48–57. doi: https://doi.org/10.37190/ppmp/132463

- Raiymbekov, Y., Besterekov, U., Abdurazova, P., Nazarbek, U. (2022). Review of methods and technologies for the enrichment of low-grade phosphorites. Reviews in Inorganic Chemistry, 42 (4), 385–395. doi: https://doi.org/10.1515/revic-2021-0041

- Cielensky, S., Benchernine, N., Watkowski, T. (1987). Travaux de prospection et d’évaluation des phosphates dans la région de Bir El Ater. Rapport interne, Entreprise de Recherche et d’Exploration Minière.

- Benabdeslam, N., Bouzidi, N., Atmani, F., Boucif, R., Sakhri, A. (2018). The effect of the parameters of the grinding on the characteristics of the deposit phosphate ore of Kef Es Sennoun, Djebel onk-tébessa, Algeria. International Journal of Materials and Metallurgical Engineering, 12 (7), 319–326. doi: https://doi.org/10.5281/zenodo.1317342

- Tahri, T., Narsis, S., Souici, Z. C., Bezzi, N., Sekiou, O., Amrane, T. et al. (2023). Mineralogical and chemical characteristics of phosphates from the djebel onk deposits. Geologica Macedonica, 37 (2), 99–109. doi: https://doi.org/10.46763/geol23372099t

- Salhi, R., Nettour, D., Chettibi, M., Gherbi, C., Benselhoub, A., Bellucci, S. (2023). Characterization of phosphate wastes of Djebel Onk mining complex for a sustainable environmental management. Technology Audit and Production Reserves, 3 (3 (71)), 11–19. doi: https://doi.org/10.15587/2706-5448.2023.278893

- Kechiched, R., Laouar, R., Bruguier, O., Kocsis, L., Salmi-Laouar, S., Bosch, D. et al. (2020). Comprehensive REE + Y and sensitive redox trace elements of Algerian phosphorites (Tébessa, eastern Algeria): A geochemical study and depositional environments tracking. Journal of Geochemical Exploration, 208, 106396. doi: https://doi.org/10.1016/j.gexplo.2019.106396

- Zhou, W., Apkarian, R., Wang, Z. L., Joy, D. (2006). Fundamentals of Scanning Electron Microscopy (SEM). Scanning Microscopy for Nanotechnology, 1–40. doi: https://doi.org/10.1007/978-0-387-39620-0_1

- El Ouardi, E. M., Zeroual, A., Khallouq, K., Darfi, S., Jedaa, A. (2020). Impact of Washing Followed by Calcination on the Quality of Bouchane Phosphate of Morocco. International Journal of Design & Nature and Ecodynamics, 15 (4), 555–563. doi: https://doi.org/10.18280/ijdne.150413

- Ruan, Y., He, D., Chi, R. (2019). Review on Beneficiation Techniques and Reagents Used for Phosphate Ores. Minerals, 9 (4), 253. doi: https://doi.org/10.3390/min9040253

- Ait Merzeg, F., Bezzi, N. (2019). Optimisation of the flotation parameters on the enrichment of phosphate ore (Algeria). Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 3. doi: https://doi.org/10.29202/nvngu/2019-3/4

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Imane Attafi, Abdelaziz Idres, Zohir Mekti, Amina Bouras, Aissa Benselhoub, Farid Ait Merzeg, Nadiia Dovbash, Stefano Bellucci

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.