Study of the feasibility of valorizing phosphate ore by electrostatic separation

DOI:

https://doi.org/10.15587/2706-5448.2024.300766Keywords:

electrostatic separation, triboelectric charge, phosphate ore, valorization, enrichment, magnesium carbonateAbstract

The object of this research is the phosphate serves, as a fundamental and crucial raw material with diverse applications, primarily utilized in producing phosphoric acid and fertilizers. However, dolomitic impurities within the ore can greatly impede its effectiveness. Therefore, it is essential to minimize these impurities to the lowest feasible levels to mitigate their adverse effects. This ensures optimal performance and quality in various industries reliant on phosphate, promoting efficiency and sustainability in the production process. Through a comprehensive assessment, it becomes feasible to gauge the enrichment potential and propose viable methods to realize it. Among these methods, flotation stands out as one of the most effective for enhancing phosphate ore, despite its inherent drawbacks of costliness and environmental impact stemming from chemical reagents.

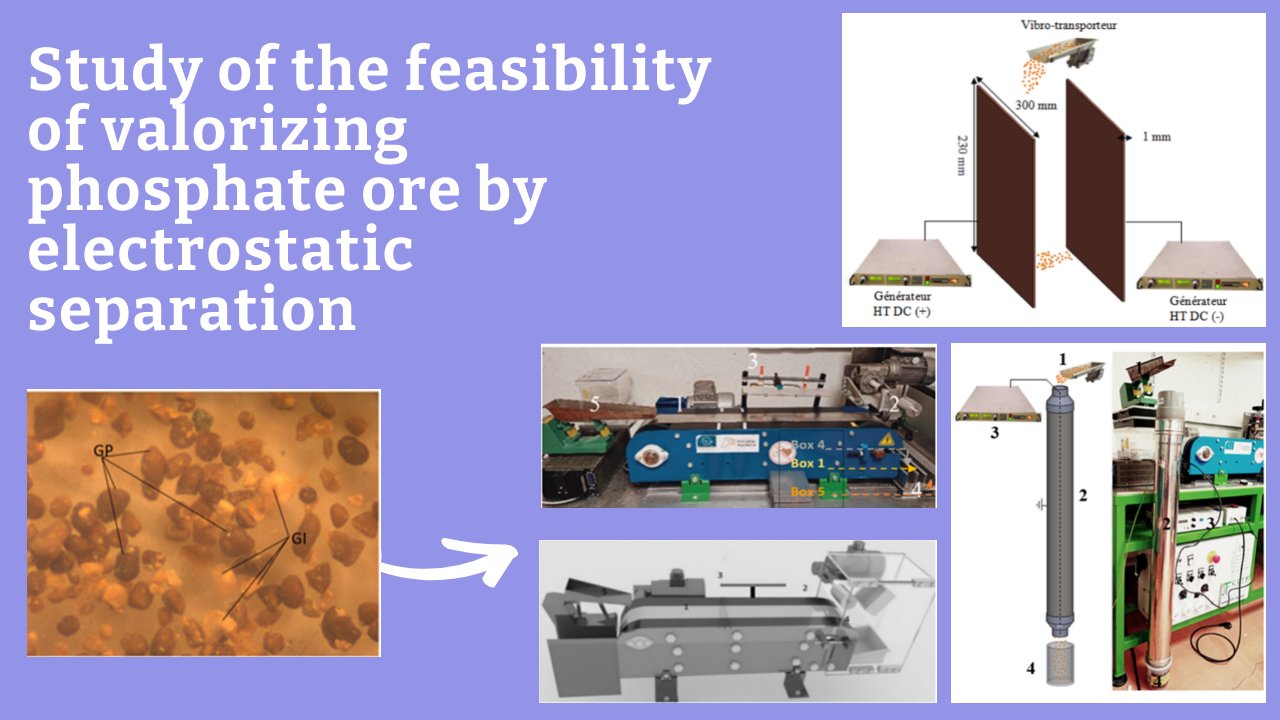

This study endeavors to investigate the feasibility of employing electrostatic separation as an alternative method for enriching phosphate ore sourced from the Tebessa region in Algeria. Such exploration aims to offer insights into potentially more sustainable and economically viable approaches to ore enrichment in the region of Bir Elater Wilaya of Tebessa. Tests were carried out using different types of electrostatic separators at the Angouleme site of the PPRIME Institute: a multifunctional metal-belt-type separator, a free-fall plate-electrodes-type separator and an electrostatic separator with coaxial wire – cylinder electrode system. The experimental findings demonstrate significant promise, indicating that electrostatic separation enhanced the P2O5 content from 25 % to 29 % in an untreated phosphate ore sample. Simultaneously, it efficiently eliminated 82.80 % of MgO, achieving a P2O5 recovery rate more than 80 % and a yield of 70 %. Consequently, employing this method proves effective in reducing the MgO content of the ore to below than 1 %, aligning with industrial standards for commercial phosphate products. This underscores the viability of electrostatic separation as a viable and efficient technique in phosphate ore processing, offering substantial improvements in both quality and yield.

References

- Sobhy, A., Tao, D. (2014). Innovative RTS Technology for Dry Beneficiation of Phosphate. Procedia Engineering, 83, 111–121. doi: https://doi.org/10.1016/j.proeng.2014.09.020

- Salhi, R., Nettour, D., Chettibi, M., Gherbi, C., Benselhoub, A., Bellucci, S. (2023). Characterization of phosphate wastes of Djebel Onk mining complex for a sustainable environmental management. Technology Audit and Production Reserves, 3 (3 (71)), 11–19. doi: https://doi.org/10.15587/2706-5448.2023.278893

- Nettour, D., Chettibi, M., Bulut, G., Benselhoub, A. (2019). Beneficiation of phosphate sludge rejected from Djebel Onk plant (Algeria). Mining of Mineral Deposits, 13 (4), 84–90. doi: https://doi.org/10.33271/mining13.04.084

- Nettour, D., Chettibi, M., Bouhedja, A., Bulut, G. (2018). Determination of physicochemical parameters of Djebel Onk phosphate flotation (Algeria). Naukovyi Visnyk Natsionalnoho Hirnychoho Universytetu, 4, 43–49. doi: https://doi.org/10.29202/nvngu/2018-4/8

- Bittnera, J. D., Gasiorowskia, S. A., Hracha, F. J., Guicherdb, H. (2015). Electrostatic beneficiation of phosphate ores: Review of past work and discussion of an improved separation system. Procedia Engineering, 1–11.

- Abouzeid, A.-Z. M. (2008). Physical and thermal treatment of phosphate ores – An overview. International Journal of Mineral Processing, 85 (4), 59–84. doi: https://doi.org/10.1016/j.minpro.2007.09.001

- Ren, J., Huang, Y., Yao, J., Zheng, S., Zhao, Y., Hou, Y. et al. (2023). The role of reactive phosphate species in the abatement of micropollutants by activated peroxymonosulfate in the treatment of phosphate-rich wastewater. Water Research, 243, 120341. doi: https://doi.org/10.1016/j.watres.2023.120341

- Ptáček, P. (2016). Apatites and their synthetic analogues: Synthesis, Structure, Properties and Applications. BoD-Books on Demand. doi: https://doi.org/10.5772/59882

- Nagoya, S., Nakamichi, S., Kawase, Y. (2019). Mechanisms of phosphate removal from aqueous solution by zero-valent iron: A novel kinetic model for electrostatic adsorption, surface complexation and precipitation of phosphate under oxic conditions. Separation and Purification Technology, 218, 120–129. doi: https://doi.org/10.1016/j.seppur.2019.02.042

- Zhengxing, G., Zhizhong, G. (1999). Development of new technology for beneficiation of florida dolomitic phosphate resources. Available at: https://fipr.floridapoly.edu/library-and-publications/publications/development-of-new-technology-for-beneficiation-of-florida-dolomitic-phosphate-resources.php

- Gu, Z., Peng, F. F. (2010). Dolomite Flotation of High MgO Phosphate Pebble Using Different Particle Size Feed. Beneficiation of Phosphate, Technology Advance and Adoption. SME Publication, 327–333.

- Feasby, D. (1890). Free-fall electrostatic separation of phosphate and calcite particles. Minerals Research Laboratory, Labs, 1869, 1890, 1985, 3021, 3038.

- Safhi, A. el M., Amar, H., El Berdai, Y., El Ghorfi, M., Taha, Y., Hakkou, R. et al. (2022). Characterizations and potential recovery pathways of phosphate mines waste rocks. Journal of Cleaner Production, 374, 134034. doi: https://doi.org/10.1016/j.jclepro.2022.134034

- Dascalescu, L., Zeghloul, T., Iuga, A. (2016). Electrostatic separation of metals and plastics from waste electrical and electronic equipment. WEEE Recycling. Elsevier, 75–106. doi: https://doi.org/10.1016/b978-0-12-803363-0.00004-3

- Messal, S., Zeghloul, T., Mekhalef Benhafssa, A., Dascalescu, L. (2017). Belt-Type Corona-Electrostatic Separator for the Recovery of Conductive and Nonconductive Products From Micronized Wastes. IEEE Transactions on Industry Applications, 53 (2), 1424–1430. doi: https://doi.org/10.1109/tia.2016.2622684

- Chang, J. S., Kelly, A. J., Crowley, J. M. (1995). Handbook of electrostatic processes. CRC Press, 780. doi: https://doi.org/10.1201/9781315214559

- Fuerstenau, M. C., Han, K. N. (Eds.). (2003). Principles of mineral processing. SME.

- Rapport des travaux de recherche du gisement de phosphate de Djebel Onk, Documentation libre de la Direction d’Etudes et de Développement (2019). SOMIPHOS, Djebel Onk, Tébessa, Algérie, Rapport inédit. Office DED.

- Chlahbi, S., Belem, T., Elghali, A., Rochdane, S., Zerouali, E., Inabi, O., Benzaazoua, M. (2023). Geological and Geomechanical Characterization of Phosphate Mine Waste Rock in View of Their Potential Civil Applications: A Case Study of the Benguerir Mine Site, Morocco. Minerals, 13 (10), 1291. doi: https://doi.org/10.3390/min13101291

- Amar, H., Benzaazoua, M., Elghali, A., Hakkou, R., Taha, Y. (2022). Waste rock reprocessing to enhance the sustainability of phosphate reserves: A critical review. Journal of Cleaner Production, 381, 135151. doi: https://doi.org/10.1016/j.jclepro.2022.135151

- Qian, K., Zhang, Y., Dong, Q., Shao, Y., Cheng, Z., Ju, J. et al. (2023). Enhancement of corrosion resistance and antibacterial properties of PEO coated AZ91D Mg alloy by copper- and phosphate-based sealing treatment. Corrosion Science, 219, 111218. doi: https://doi.org/10.1016/j.corsci.2023.111218

- Konadu-Amoah, B., Hu, R., Ndé-Tchoupé, A. I., Gwenzi, W., Noubactep, C. (2022). Metallic iron (Fe0)-based materials for aqueous phosphate removal: A critical review. Journal of Environmental Management, 315, 115157. doi: https://doi.org/10.1016/j.jenvman.2022.115157

- Šutka, A., Lapčinskis, L., He, D., Kim, H., Berry, J. D., Bai, J., Knite, M. et al. (2023). Engineering Polymer Interfaces: A Review toward Controlling Triboelectric Surface Charge. Advanced Materials Interfaces, 10 (26). doi: https://doi.org/10.1002/admi.202300323

- El Ghorfi, M., Inabi, O., Amar, H., Taha, Y., Elghali, A., Hakkou, R., Benzaazoua, M. (2024). Design and Implementation of Sampling Wells in Phosphate Mine Waste Rock Piles: Towards an Enhanced Composition Understanding and Sustainable Reclamation. Minerals, 14 (3), 286. doi: https://doi.org/10.3390/min14030286

- Nepfumbada, C., Tavengwa, N. T., Masindi, V., Foteinis, S., Chatzisymeon, E. (2023). Recovery of phosphate from municipal wastewater as calcium phosphate and its subsequent application for the treatment of acid mine drainage. Resources, Conservation and Recycling, 190, 106779. doi: https://doi.org/10.1016/j.resconrec.2022.106779

- El Bamiki, R., Séranne, M., Parat, F., Aubineau, J., Chellai, E. H., Marzoqi, M., Bodinier, J.-L. (2023). Post-phosphogenesis processes and the natural beneficiation of phosphates: Geochemical evidence from the Moroccan High Atlas phosphate-rich sediments. Chemical Geology, 631, 121523. doi: https://doi.org/10.1016/j.chemgeo.2023.121523

- Aarab, I., Derqaoui, M., Amari, K. E., Yaacoubi, A., Abidi, A., Etahiri, A., Baçaoui, A. (2022). Flotation Tendency Assessment Through DOE: Case of Low-Grade Moroccan Phosphate Ore. Mining, Metallurgy & Exploration, 39 (4), 1721–1741. doi: https://doi.org/10.1007/s42461-022-00647-4

- Wang, B., Zhou, Z., Xu, D., Wu, J., Yang, X., Zhang, Z., Yan, Z. (2022). A new enrichment method of medium–low grade phosphate ore with high silicon content. Minerals Engineering, 181, 107548. doi: https://doi.org/10.1016/j.mineng.2022.107548

- Li, W., Huang, Z., Wang, H., Liu, R., Ouyang, L., Shuai, S. et al. (2023). Froth flotation separation of phosphate ore using a novel hammer-like amidoxime surfactant. Separation and Purification Technology, 307, 122817. doi: https://doi.org/10.1016/j.seppur.2022.122817

- Xiao, J., Lu, T., Zhuang, Y., Jin, H. (2022). A Novel Process to Recover Gypsum from Phosphogypsum. Materials, 15 (5), 1944. doi: https://doi.org/10.3390/ma15051944

- El-bahi, A., Taha, Y., Ait-Khouia, Y., Hakkou, R., Benzaazoua, M. (2023). Advancing phosphate ore minerals separation with sustainable flotation reagents: An investigation into highly selective biobased depressants. Advances in Colloid and Interface Science, 317, 102921. doi: https://doi.org/10.1016/j.cis.2023.102921

- Cheng, S., Li, W., Han, Y., Sun, Y., Gao, P., Zhang, X. (2024). Recent process developments in beneficiation and metallurgy of rare earths: A review. Journal of Rare Earths, 42 (4), 629–642. doi: https://doi.org/10.1016/j.jre.2023.03.017

- Corchado-Albelo, J. L., Alagha, L. (2023). Studies on the Enrichment Feasibility of Rare Earth-Bearing Minerals in Mine Tailings. Minerals, 13 (3), 301. doi: https://doi.org/10.3390/min13030301

- Ao, X., Yuan, X., Chen, J., Wang, M., Dong, W. (2023). Effects of metallic ions on fine-grained phosphate-rock particle dispersion and aggregation. Journal of Dispersion Science and Technology, 1–11. doi: https://doi.org/10.1080/01932691.2023.2263539

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Nesrine Derrardjia, Djamel Nettour, Mohamed Chettibi, Rachid Chaib, Thami Zeghloul, Lucien Dascalescu, Djillali Aouimeur

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.