The choice of rational adjustment of the chemical composition of iron melted in an electric arc furnace on the basis of technological audit of serial films

DOI:

https://doi.org/10.15587/2706-5448.2024.301259Keywords:

electric arc smelting, chemical composition of cast iron, technological audit, serial smelting, charge materials, ferroalloysAbstract

The object of research in the work is cast iron of the SCh20 grade according to GOST 1412-85 (DSTU EN 1561, EN-GJL-200), which is melted in an electric arc furnace. In this work, the parameters of serial smeltings of cast iron used for machine-building castings were determined, which were used to select the content of elements of the chemical composition.

The existing problem is that the impossibility of taking into account many factors influencing the formation of the chemical composition of cast iron during smelting leads to deviations of the chemical composition from the requirements regulated by the technical conditions. The main reason for this is the uncontrollability of the chemical composition of the charge materials and the difficulty of accurately determining the soot of the elements during the smelting process. This can lead to the formation of a shortage of cast iron, or to excessive costs for smelting, associated with the need for additional technological operations and the use of additional materials to eliminate detected deviations of the composition from the requirements.

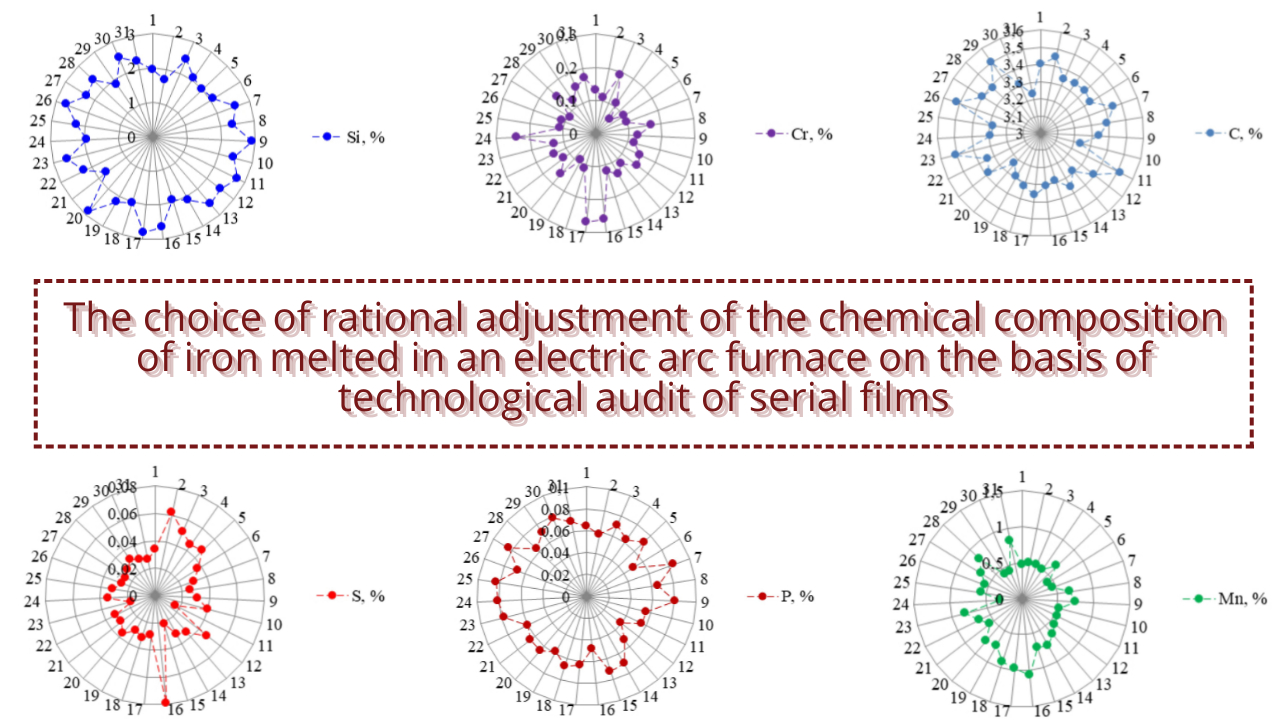

The procedure of technological audit of serial smeltings is proposed, the feature of which is a comprehensive assessment of the actual indicators of smelting. They include: mathematical expectations of the content of the elements of the chemical composition, estimates of their dispersions, root mean square deviations, systematic errors, scattering fields and deviations of the lower and upper limits of the content of each element from the lower and upper limits required by the technical conditions. The results of such an audit are the possibility of calculating corrective combinations of charge materials and ferroalloys, which eliminate inaccuracies in the calculation of the charge and the determination of the heat of the elements during the smelting process.

As a result of the audit of a sample of 31 serial smelters, it was established that the average content of the elements C, Mn, Si, Cr exceeds the average required by technical conditions. These deviations are: +0.04 % C, +0.06 % Mn, +0.038 % Si, +0.06 % Cr. To compensate for these deviations, the following combination of charge materials and ferroalloys, which are introduced into the melt before delivering the cast iron to the casting area, is proposed: 44 kg of steel scrap +88 kg of recycled iron.

The presented study will be useful for machine-building enterprises that have foundries in their structure, where iron is melted for the production of castings.

References

- Demin, D. A. (2012). Synthesis of control systems of technological processes of electric arc melting of cast iron. Eastern-European Journal of Enterprise Technologies, 2 (10 (56)), 4–9. doi: https://doi.org/10.15587/1729-4061.2012.3881

- Domin, D. (2013). Application of artificial orthogonalization in search for optimal control of technological processes under uncertainty. Eastern-European Journal of Enterprise Technologies, 5 (9 (65)), 45–53. doi: https://doi.org/10.15587/1729-4061.2013.18452

- Trufanov, I. D., Chumakov, K. I., Bondarenko, A. A. (2005). Obshheteoreticheskie aspekty razrabotki stokhasticheskoi sistemy avtomatizirovannoi ekspertnoi otsenki dinamicheskogo kachestva proizvodstvennykh situatsii elektrostaleplavleniia. Eastern-European Journal of Enterprise Technologies, 6 (2 (18)), 52–58.

- Trufanov, I. D., Metelskii, V. P., Chumakov, K. I., Lozinskii, O. Iu., Paranchuk, Ia. S. (2008). Energosberegaiushhee upravlenie elektrotekhnologicheskim kompleksom kak baza povysheniia energoeffektivnosti metallurgii stali. Eastern-European Journal of Enterprise Technologies, 6 (1 (36)), 22–29.

- Fourlakidis, V., Diószegi, A. (2014). A generic model to predict the ultimate tensile strength in pearlitic lamellar graphite iron. Materials Science and Engineering: A, 618, 161–167. doi: https://doi.org/10.1016/j.msea.2014.08.061

- Demin, D. (2017). Strength analysis of lamellar graphite cast iron in the «carbon (C) – carbon equivalent (Ceq)» factor space in the range of C = (3,425-3,563) % and Ceq = (4,214-4,372) %. Technology Audit and Production Reserves, 1 (1 (33)), 24–32. doi: https://doi.org/10.15587/2312-8372.2017.93178

- Endo, M., Yanase, K. (2014). Effects of small defects, matrix structures and loading conditions on the fatigue strength of ductile cast irons. Theoretical and Applied Fracture Mechanics, 69, 34–43. doi: https://doi.org/10.1016/j.tafmec.2013.12.005

- Popov, S., Frolova, L., Rebrov, O., Naumenko, Y., Postupna, О., Zubko, V., Shvets, P. (2022). Increasing the mechanical properties of structural cast iron for machine-building parts by combined Mn – Al alloying. EUREKA: Physics and Engineering, 1, 118–130. doi: https://doi.org/10.21303/2461-4262.2022.002243

- Frolova, L., Shevchenko, R., Shpyh, A., Khoroshailo, V., Antonenko, Y. (2021). Selection of optimal Al–Si combinations in cast iron for castings for engineering purposes. EUREKA: Physics and Engineering, 2, 99–107. doi: https://doi.org/10.21303/2461-4262.2021.001694

- Kharchenko, S., Barsuk, A., Karimova, N., Nanka, A., Pelypenko, Y., Shevtsov, V. et al. (2021). Mathematical model of the mechanical properties of Ti-alloyed hypoeutectic cast iron for mixer blades. EUREKA: Physics and Engineering, 3, 99–110. doi: https://doi.org/10.21303/2461-4262.2021.001830

- Frolova, L., Barsuk, A., Nikolaiev, D. (2022). Revealing the significance of the influence of vanadium on the mechanical properties of cast iron for castings for machine-building purpose. Technology Audit and Production Reserves, 4 (1 (66)), 6–10. doi: https://doi.org/10.15587/2706-5448.2022.263428

- Chugun peredelnyi DSTU 3133-95 (GOST 805-95). Available at: https://issuu.com/revanthtt941/docs/dstu_3133-95__gost_805-95_

- Demin, D. (2019). Development of «whole» evaluation algorithm of the control quality of «cupola – mixer» melting duplex process. Technology Audit and Production Reserves, 3 (1 (47)), 4–24. doi: https://doi.org/10.15587/2312-8372.2019.174449

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Denis Nikolaev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.