Improving the design of a jaw shutter to increase the efficiency of material crushing

DOI:

https://doi.org/10.15587/2706-5448.2024.302148Keywords:

jaw crusher, moving jaw, fixed jaw, longitudinal protrusions, material crushing efficiency, contact stressesAbstract

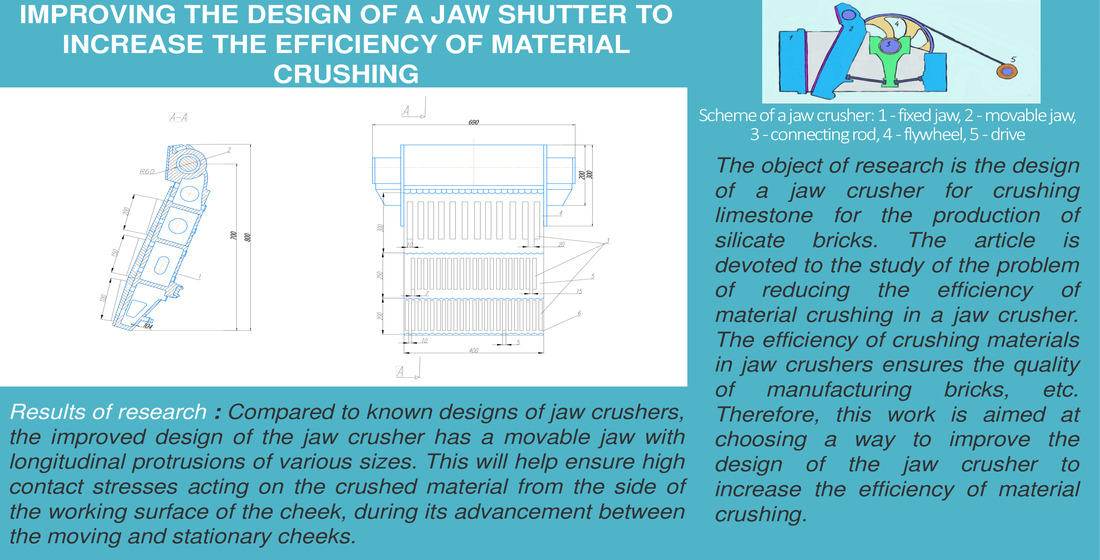

The object of research is the design of a jaw crusher for crushing limestone for the production of silicate bricks. The article is devoted to the study of the problem of reducing the efficiency of material crushing in a jaw crusher. The efficiency of crushing materials in jaw crushers ensures the quality of manufacturing bricks, etc. Therefore, this work is aimed at choosing a way to improve the design of the jaw crusher to increase the efficiency of material crushing.

The article defines the classification of jaw crushers, their advantages and disadvantages, describes the principle of operation of the most widely used jaw crushers in the construction industry with simple and complex rocking of the cheek. A literature and patent search and analysis of existing methods of increasing the efficiency of material crushing in jaw crushers was carried out. As a result of the literature and patent search, one of the methods of improving the design of the jaw crusher to increase the efficiency of material crushing based on the use of longitudinal protrusions on the movable jaw was selected and proposed. The protrusions on the flat sections of the working surface of the plate are made with the same pitch of their location within each section with a decrease in the pitch of the protrusions in the direction of distance from the upper part of the plate. The considered design of the movable jaw with longitudinal protrusions in the jaw crusher will ensure reliable pulling of the material into the gap between the movable and stationary jaws, which ensures high contact stresses acting on the crushed material from the side of the working surface of the plate.

Compared to known designs of jaw crushers, the improved design of the movable jaw in the jaw crusher with longitudinal protrusions of different sizes with a decrease in their size in the direction from the upper part of the plate on three sections of the working surface of the plate will contribute to ensuring high contact stresses acting on the crushed material from the side of the working surface cheeks, during its advancement between the moving and stationary cheeks and increases the efficiency of destruction of various materials.

Compared to known designs of jaw crushers, the improved design of the jaw crusher has a movable jaw with longitudinal protrusions of various sizes. At the same time, these protrusions are located on three sections of the working surface of the plate with a decrease in their size in the direction from the upper part of the plate. This will help ensure high contact stresses acting on the crushed material from the side of the working surface of the cheek, during its advancement between the moving and stationary cheeks. Also, this design of the working jaw of the jaw crusher with longitudinal protrusions helps to increase the efficiency of destruction of various materials.

References

- Promyslovi drobarky, shredery, podribniuvachi. Available at: https://konvejer.com/ua/blog/promislovi-drobarki-shrederi-podribnyuvachi#3

- Shchokova drobarka. Available at: https://mcet.com.ua/dictionary/shhokova-drobarka/

- Nazarenko, I. I., Mishchuk, Ye. O. (2010). Analiz protsesu ruinuvannia v shchokovykh drobarkakh. Tekhnika budivnytstva, 24, 32–37. Available at: https://repositary.knuba.edu.ua/server/api/core/bitstreams/f308da9e-48bc-4a82-a634-1b0d787d1522/content

- Courtney, A. Y. (2019). SME Mineral Processing and Extractive Metallurgy Handbook: Society for Mining, Metallurgy and Exploration, 2197. Available at: https://books.google.de/books?id=4hKGDwAAQBAJ&lpg=PA367&ots=1lsqZUIjLR&dq=Research%20and%20improvement%20of%20the%20design%20of%20the%20jaw%20crusher&lr&hl=uk&pg=PA371#v=onepage&q&f=false

- Fedoskina, O. V., Matsiuk, I. M., Batus, V. V. (2020). The vibration crusher plates shape features. Contemporary Innovation Technique of the Engineering Personnel Training for the Mining and Transport Industry, 7 (1), 43–47. Available at: https://ir.nmu.org.ua/bitstream/handle/123456789/156587/citep2020-43-46.pdf?sequence=1

- Karvatskyi, A. Ya., Leleka, S. V., Mikulonok, I. O., Panov, Ye. M., Shcherbyna, V. Yu., Sheliuk, O. D. (2021). Pat. No. 146272 UA. Rukhoma shchoka shchokovoi drobarky: opys do patentu na korysnu model. MPK B02C 1/02 (2006.01), B02C 1/10 (2006.01); No. u202006364; declareted: 01.10.2020; published: 03.02.2021, Bul. No. 5, 4.

- Ramkrushna, S. M., Sunil, J. R. (2013). A Review on Study of Jaw Plates of Jaw Crusher. International Journal of Modern Engineering Research, 3 (1), 518–522. Available at: https://citeseerx.ist.psu.edu/document?repid=rep1&type=pdf&doi=6f24043851754ecfb74637805af0733b7b147813

- Kavi, N. (2010). Optimum Design and Analysis of Swinging Jaw Plate of a Single Toggle Jaw Crusher. Department of Mechanical Engineering National Institute of Technology, Rourkela, 95. Available at: https://www.researchgate.net/profile/B-Deepak/publication/283485893_Optimum_design_and_analysis_of_the_swinging_jaw_plate_of_a_single_toggle_jaw_crusher/links/5639f07608ae4624b7608557/Optimum-design-and-analysis-of-the-swinging-jaw-plate-of-a-single-toggle-jaw-crusher.pdf

- Kovalenko, A. S., Bocharova, O. A. (2019). Research of durability and corrosion resistance of machines for the production of building materials. Nauka ta vyrobnytstvo, 21, 114–121. doi: https://doi.org/10.31498/2522-9990212019187537

- Nazarenko, I. I., Mishchuk, Ye. O. (2009). Analiz kinematyky shchokovoi drobarky. Teoriia i praktyka budivnytstva, 5, 39–43. Available at: https://repositary.knuba.edu.ua/server/api/core/bitstreams/3d92d298-e393-4fba-8a46-95a17fb57586/content

- Kotrechko, O. O. (2009). Pat. No. 40933 UA. Shchokova drobarka. MPK (2009) B02C 1/00.; No. u200814538; declareted: 17.12.2008; published: 27.04.2009, Bul. No. 8, 2.

- Mikulonok, I. O. (2014). Mekhanichni, hidromekhanichni i masoobminni protsesy ta obladnannia khimichnoi tekhnolohii. Kyiv: NTUU «KPI», 340.

- Biletskyi, V. S., Oliinyk, T. A., Smyrnov, V. O., Skliar, L. V. (2019). Tekhnika ta tekhnolohiia zbahachennia korysnykh kopalyn. Chastyna I. Pidhotovchi protsesy. Kryvyi Rih: Vydavets FOP Cherniavskyi D. O., 200.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Iryna Kazak, Dmytro Sidorov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.