Determination of the limits of operational loads of rubber shock absorbers during compression

DOI:

https://doi.org/10.15587/2706-5448.2024.302534Keywords:

rubber shock absorber, vibration insulator, operational loads, static compression, rubber hardness, shock absorber bendingAbstract

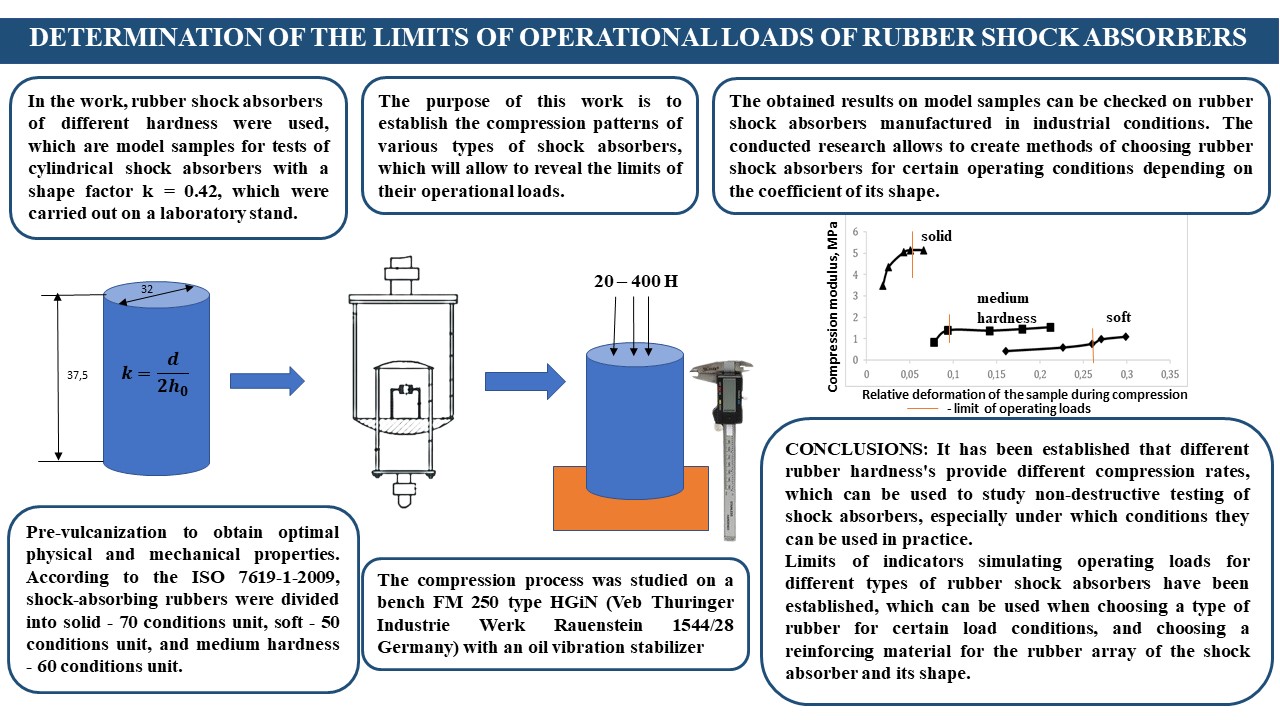

Determining the limits of operational loads of rubber shock absorbers is an urgent task in the development of methods of non-destructive control of their condition. Therefore, the object of research is the influence of the limit values of the parameters of rubber shock absorbers during their static compression under harsh operating conditions. One of the most problematic issues is cylindrical shock absorbers with a form factor of less than 1.0.

In the work, rubber shock absorbers of different hardness were used, which are model samples for tests of cylindrical shock absorbers with a form factor of 0.42, which were carried out on a laboratory stand. The study of compression process of rubber shock absorbers is an urgent task in modelling the conditions of their operation. The obtained results make it possible to simulate the most effective diagnostic parameter of rubber shock absorbers during compression and to establish its limit and permissible values. It has been established that different rubber hardnesses provide different compression rates, which can be used to study non-destructive testing of shock absorbers, especially under which conditions they can be used in practice. According to the indicators of relative deformation during compression, the use of rubber shock absorbers from the group of high hardness is recommended for more severe load conditions during exploitation. Soft and medium-hard rubbers are characterized by an increased relative deformation of the shock absorber's geometric size (height) during compression, which can lead to their destruction under increased loads.

The obtained results on model samples can be checked on rubber shock absorbers manufactured in industrial conditions. The conducted research allows to create methods of choosing rubber shock absorbers for certain operating conditions depending on the coefficient of its shape. Limits of indicators simulating operating loads for different types of rubber shock absorbers have been established, which can be used when choosing a type of rubber for certain load conditions, and choosing a reinforcing material for the rubber array of the shock absorber and its shape.

References

- Poturaev, V. N. (1983). Rezinometallicheskii amortizator. Kyiv: Nauch. Mysl, 298.

- Ebich, Iu. R., Emelianov, Iu. V., Zybailo, S. N. (2005). Otcenka ekspluatatcionnykh svoistv rezinometallicheskikh soedinenii. Voprosy khimii i khimicheskoi tekhnologii, 115–118.

- Kasperovich, A. V., Shashok, Zh. S., Vishnevskii, K. V. (2014). Tekhnologiia proizvodstva rezinotekhnicheskikh izdelii. Minsk, 65.

- Poturaev, V. N. (1975). Prikladnaia mekhanika reziny. Kyiv: Nauch. Mysl, 216.

- Dyrda, V., Kobets, A., Bulat, I., Lapin, V., Lysytsia, N., Ahaltsov, H., Sokol, S. (2019). Vibroseismic protection of heavy mining machines, buildings and structures. E3S Web of Conferences, 109, 00022. doi: https://doi.org/10.1051/e3sconf/201910900022

- Long, X.-H., Ma, Y.-T., Yue, R., Fan, J. (2018). Experimental study on impact behaviors of rubber shock absorbers. Construction and Building Materials, 173, 718–729. doi: https://doi.org/10.1016/j.conbuildmat.2018.04.077

- Grządziela, A., Kluczyk, M. (2021). Shock Absorbers Damping Characteristics by Lightweight Drop Hammer Test for Naval Machines. Materials, 14 (4), 772. doi: https://doi.org/10.3390/ma14040772

- Ucar, H., Basdogan, I. (2017). Dynamic characterization and modeling of rubber shock absorbers: A comprehensive case study. Journal of Low Frequency Noise, Vibration and Active Control, 37 (3), 509–518. doi: https://doi.org/10.1177/1461348417725954

- Shimanoe, S., Hasegawa, K., Kawashima, K., Shoji, G. (2001). Dynamic propertiers of rubber-type shock absorbers subjected to pounding force. Doboku Gakkai Ronbunshu, 2001 (675), 219–234. doi: https://doi.org/10.2208/jscej.2001.675_219

- Kluczyk, M., Grządziela, A., Pająk, M., Muślewski, Ł., Szeleziński, A. (2022). The Fatigue Wear Process of Rubber-Metal Shock Absorbers. Polymers, 14 (6), 1186. doi: https://doi.org/10.3390/polym14061186

- Bulat, A. F., Dyrda, V. I., Grebenyuk, S. N., Agal’tsov, G. N. (2019). Methods for Evaluating the Characteristics of the Stress-Strain State of Seismic Blocks Under Operating Conditions. Strength of Materials, 51 (5), 715–720. doi: https://doi.org/10.1007/s11223-019-00129-x

- Dyrda, V., Kalgankov, Ye., Tsanidy, I., Cherniy, A., Tolstenko, A., Derkach, A., Kabat, O. (2018). Specificity of rubber-metal elements calculation with taking into account effect of bulk compression. Geo-Technical Mechanics, 138, 160–168. doi: https://doi.org/10.15407/geotm2018.01.160

- Lepetov, V. A. (1972). Raschety i konstruirovanie rezinovykh tekhnicheskikh izdelii i form. Khimiia, 348.

- Bondar, A. G., Statiukha, G. A. (1976). Planirovanie eksperimenta v khimicheskoi tekhnologii. Obshchie polozheniia, primery primerov i zadach. Kyiv: Vysshaia shkola, 219.

- Lepetov, V. A. (1976). Rezinovye tekhnicheskie izdeliia. Khimiia, 440.

- Lepetov, V. A., Iurtcev, L. N. (1973). Laboratornyi praktikum po mekhanicheskim svoistvam konstruktcionnykh materialov i raschetu konstruktcii v proizvodstve rezinovykh izdelii. MKhTI, 96.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Igor Assin, Sergiy Zybaylo

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.