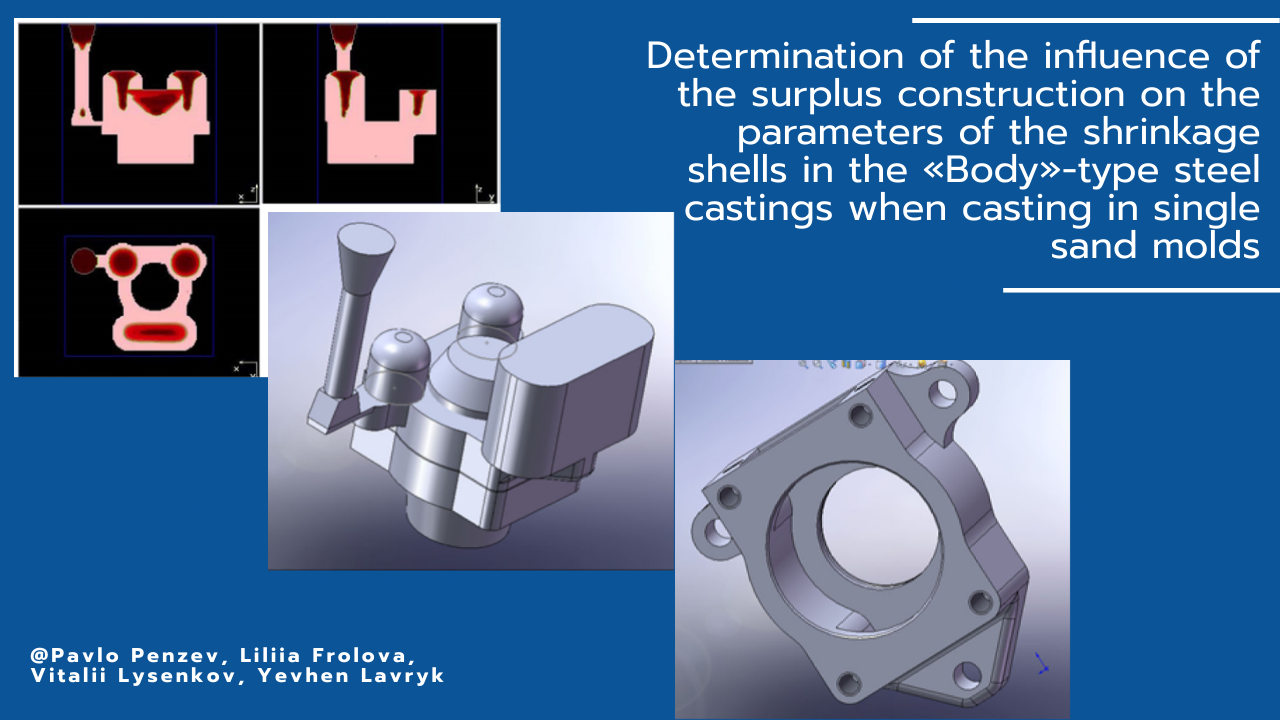

Determination of the influence of the surplus construction on the parameters of the shrinkage shells in the «Body»-type steel castings when casting in single sand molds

DOI:

https://doi.org/10.15587/2706-5448.2024.310424Keywords:

steel shaped castings, surplus, shrink shell, design and technological solutionsAbstract

The object of research is the technology of manufacturing «Body»-type shaped castings of the from medium carbon steel in one-time sand molds.

The existing problem is that the design of the casting and foundry equipment significantly affect the formation of internal defects in castings. This especially applies to steel castings, the technology of which is more complicated than the technology of cast iron castings due to much worse casting properties of steel.

To determine the influence of the location of surpluses on the «Body»-type steel castings of the on the formation of shrinkage shells, computer modeling was used, in the process of which 5 computer experiments were conducted with different sizes and geometries of surpluses.

According to the simulation results, it was found that with some technological options, there is a risk of the shrinkage shell penetrating into the casting body. The use of a cylindrical surplus of a rectangular cross-section with fillets ensures complete absorption of the shrink shell in the place of surplus installation. Using an excess round section at the installation location does not guarantee absorption of the shrink shell. The determining factor affecting the coefficient of increase in the depth of the shrinking shell is the excess volume. This influence can be described by a functional dependence of the logarithmic type with the coefficient of determination R2=0.82.

It was determined that the ratio of the diameter of the inlet to its height does not affect the coefficient of increase in the depth of the shrinking shell. The resulting functional dependence allows to set the excess volume that provides a minimum growth factor while simultaneously preventing excess metal consumption.

The presented study will be useful for machine-building enterprises that have foundries in their structure, where shaped castings are made in one-time sand molds.

References

- Demin, D. (2018). Investigation of structural cast iron hardness for castings of automobile industry on the basis of construction and analysis of regression equation in the factor space «carbon (C) – carbon equivalent (Ceq)». Technology Audit and Production Reserves, 3 (1 (41)), 29–36. https://doi.org/10.15587/2312-8372.2018.109097

- Demin, D. (2017). Synthesis of nomogram for the calculation of suboptimal chemical composition of the structural cast iron on the basis of the parametric description of the ultimate strength response surface. ScienceRise, 8, 36–45. https://doi.org/10.15587/2313-8416.2017.109175

- Domin, D. (2013). Artificial orthogonalization in searching of optimal control of technological processes under uncertainty conditions. Eastern-European Journal of Enterprise Technologies, 5 (9 (65)), 45–53. https://doi.org/10.15587/1729-4061.2013.18452

- Domin, D. (2013). Adaptive modeling in problems of optimal control search termovremennoy cast iron. Eastern-European Journal of Enterprise Technologies, 6 (4 (66)), 31–37. https://doi.org/10.15587/1729-4061.2013.19453

- Jiang, H., Zhang, X., Tao, C., Ai, S., Wang, Y., He, J., Yang, H., Yang, D. (2024). Casting defect region segmentation method based on dual-channel encoding–fusion decoding network. Expert Systems with Applications, 247, 123254. https://doi.org/10.1016/j.eswa.2024.123254

- Yousef, N., Parmar, C., Sata, A. (2022). Intelligent inspection of surface defects in metal castings using machine learning. Materials Today: Proceedings, 67, 517–522. https://doi.org/10.1016/j.matpr.2022.06.474

- Li, N., Wu, Q., Jiang, A., Zong, N., Wu, X., Kang, J., Jing, T. (2023). Numerical research of gas-related defects for gray cast iron during sand casting. Materials Letters, 340, 134177. https://doi.org/10.1016/j.matlet.2023.134177

- Ponomarenko, O. I., Trenev, N. S. (2013). Computer modeling of crystallization processes as a reserve of improving the quality of pistons of ICE. Technology Audit and Production Reserves, 6 (2 (14)), 36–40. https://doi.org/10.15587/2312-8372.2013.19529

- Patil, M. A., Patil, S. D., Yadav, P. H., Desai, A. A. (2023). Methoding and Defect Minimization of Center Plate Casting by Auto-CASTX1 Software. Materials Today: Proceedings, 77, 662–672. https://doi.org/10.1016/j.matpr.2022.11.286

- Li, Y., Liu, J., Zhang, Q., Huang, W. (2021). Casting defects and microstructure distribution characteristics of aluminum alloy cylinder head with complex structure. Materials Today Communications, 27, 102416. https://doi.org/10.1016/j.mtcomm.2021.102416

- Li, Y., Liu, J., Zhong, G., Huang, W., Zou, R. (2021). Analysis of a diesel engine cylinder head failure caused by casting porosity defects. Engineering Failure Analysis, 127, 105498. https://doi.org/10.1016/j.engfailanal.2021.105498

- Hodbe, G. A., Shinde, B. R. (2018). Design And Simulation Of LM 25 Sand Casting For Defect Minimization. Materials Today: Proceedings, 5 (2), 4489–4497. https://doi.org/10.1016/j.matpr.2017.12.018

- Frolova, L. (2023). Search procedure for optimal design and technological solutions to ensure dimensional and geometric accuracy of castings. Technology Audit and Production Reserves, 1 (1 (69)), 18–25. https://doi.org/10.15587/2706-5448.2023.271860

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Pavlo Penziev, Liliia Frolova, Vitalii Lysenkov, Yevhen Lavryk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.