Determination of the density of the surface which is exposed to various working bodies of the vibration plate VP-10

DOI:

https://doi.org/10.15587/2706-5448.2024.310802Keywords:

vibration, vibration installation, vibration amplitude, vibration exciter, mathematical analysis, vibration machineAbstract

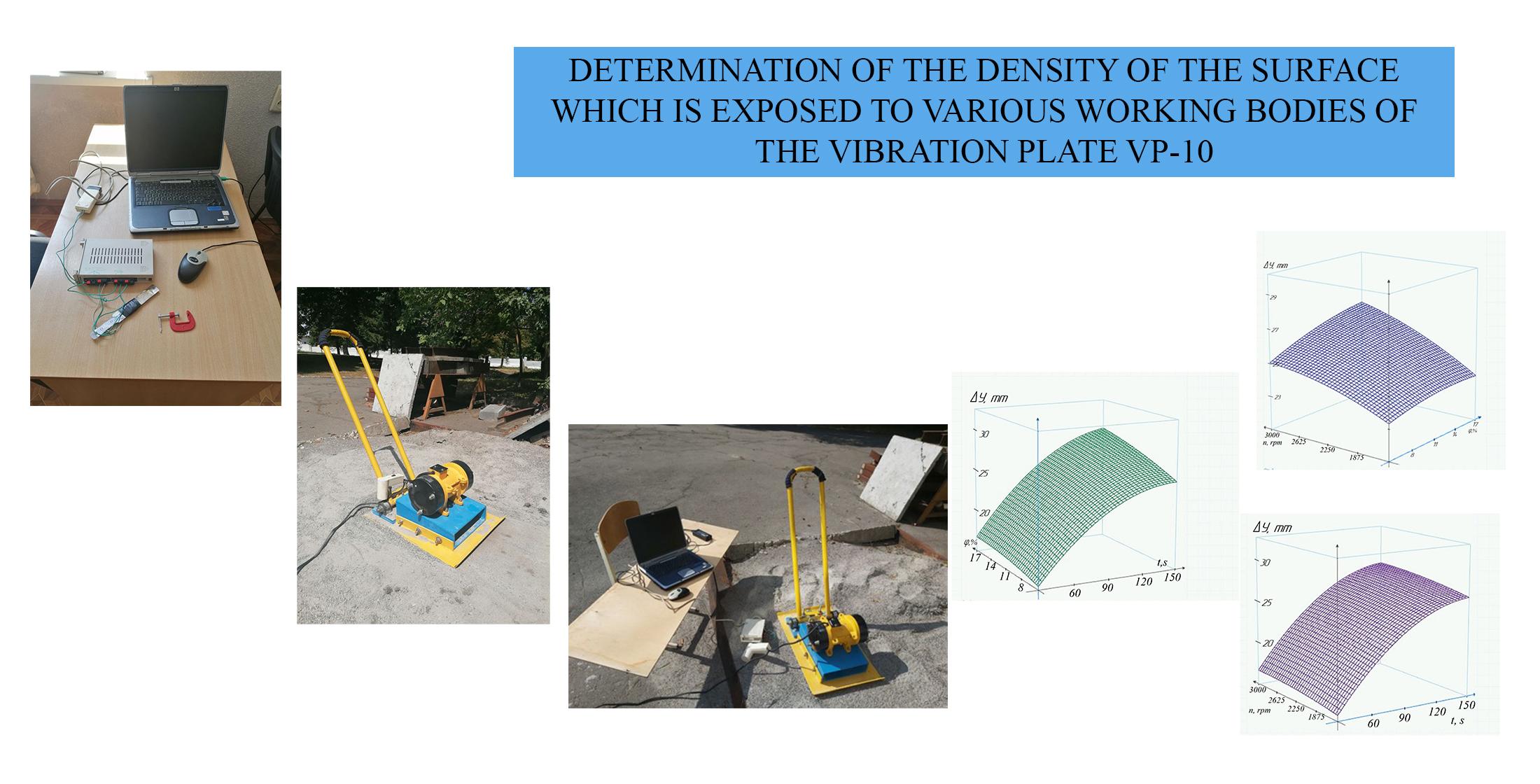

The object of research is a vibrating plate with interchangeable working bodies developed by the authors. Vibrating plates are an integral part of small mechanization equipment and are mainly intended for layer-by-layer compaction of various materials, such as sand, gravel, bituminous mixtures, etc. Vibration compaction methods are widely used in the construction of road surfaces and other infrastructure facilities. Self-propelled vibrating slabs are also used effectively in other construction processes such as compaction, trench reinforcement, land work and laying paving slabs. They ensure effective compaction of materials due to vibration.

This paper is aimed at determining the optimal equipment for compaction of materials during the construction of small objects. Analyzing the characteristics of the machines that most affect the quality of compaction, it is also necessary to evaluate their influence in specific conditions. Studies show that for each type of material, a special working body should be selected, taking into account the specific conditions and requirements for compaction, to ensure optimal quality of work.

The authors seek to consider the selection of vibrating plates and their working bodies that best meet the requirements and needs of compaction of various materials on limited construction sites. The analysis of different types of working bodies for different surfaces helps to improve the compaction process and provides optimal conditions for different types of building materials, taking into account their unique properties.

The paper examines the influence of the working body on the processed environment, in particular, analyzes the ability of various factors to influence the quality of material compaction. Special attention is paid to the influence of the geometry and size of the contact area on the sealing efficiency of each material type. Overall, this analysis can significantly improve material compaction strategies in the construction industry, contributing to improved construction quality.

References

- Nazarenko, I. I. (2007). Vibratsiini mashyny i protsesy budivelnoi industrii. Kyiv: KNUBA, 230.

- Nesterenko, M. P., Chebotarov, P. M. (2012). Analiz konstruktyvnykh osoblyvostei vibratsiinykh mashyn, yak peredumovy stvorennia kerovanoi vibratsiinoi ustanovky dlia poverkhnevoho ushchilnennia betonnykh sumishei. Haluzeve mashynobuduvannia, budivnytstvo, 1 (31), 267–275.

- Lyutenko, V., Orysenko, O., Nadobko, V. (2018). Mathematical Model for the Manual Vibration Roller Drive Mechanism Investigation. International Journal of Engineering & Technology, 7 (3.2), 232–235. https://doi.org/10.14419/ijet.v7i3.2.14409

- Lanets, O. S. (2008). Vysokoefektyvni vibratsiini mashyny z elektromahnitnym pryvodom (Teoretychni osnovy ta praktyka stvorennia). Lviv: Vyd-vo NU «Lvivska politekhnika», 324.

- Maslov, A. G., Salenko, Y. S., Maslova, N. A. (2011). Study of the interaction between a vibrating plate with cement concrete mixture. Transactions of Kremenchuk Mykhailo Ostrohradskyi National University, 67, 93–98.

- Gutiérrez, J., Ruiz, E., Trochu, F. (2013). High-frequency vibrations on the compaction of dry fibrous reinforcements. Advanced Composite Materials, 22 (1), 13–27. https://doi.org/10.1080/09243046.2013.764778

- Itkin, A. F. (2009). Vibratsionnyie mashinyi dlya formovaniya betonnyih izdeliy «Les MP». Kyiv.

- Vasyliev, A., Yakovenko, A. (2023). Vibrating machine for surface preparation and sealing. Technical sciences and technologies, 4 (34), 52–60. https://doi.org/10.25140/2411-5363-2023-4(34)-52-60

- Zelenin, A. N. (1975). Mashiny dlia zemlianykh rabot. Mashinostroenie, 422.

- Krot, O. Yu., Korobko, B. O., Krot, O. P., Virchenko, V. V. (2023). Eksperymentalni metody doslidzhen. Poltava: NUPP, 192.

- Batsaikhan, Zh. (2015). Study of the interaction of the vibration plate working body with sealed medium. Transactions of Kremenchuk Mykhailo Ostrohradskyi National University, 90, 92–97.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Andrii Yakovenko, Oleksii Vasyliev

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.