Analysis of the functional additives effect on the corrosion resistance of paint coatings

DOI:

https://doi.org/10.15587/2706-5448.2024.313656Keywords:

anti-corrosion additives, corrosion protection, salt spray, paint coatings, durability of lacquer coatingsAbstract

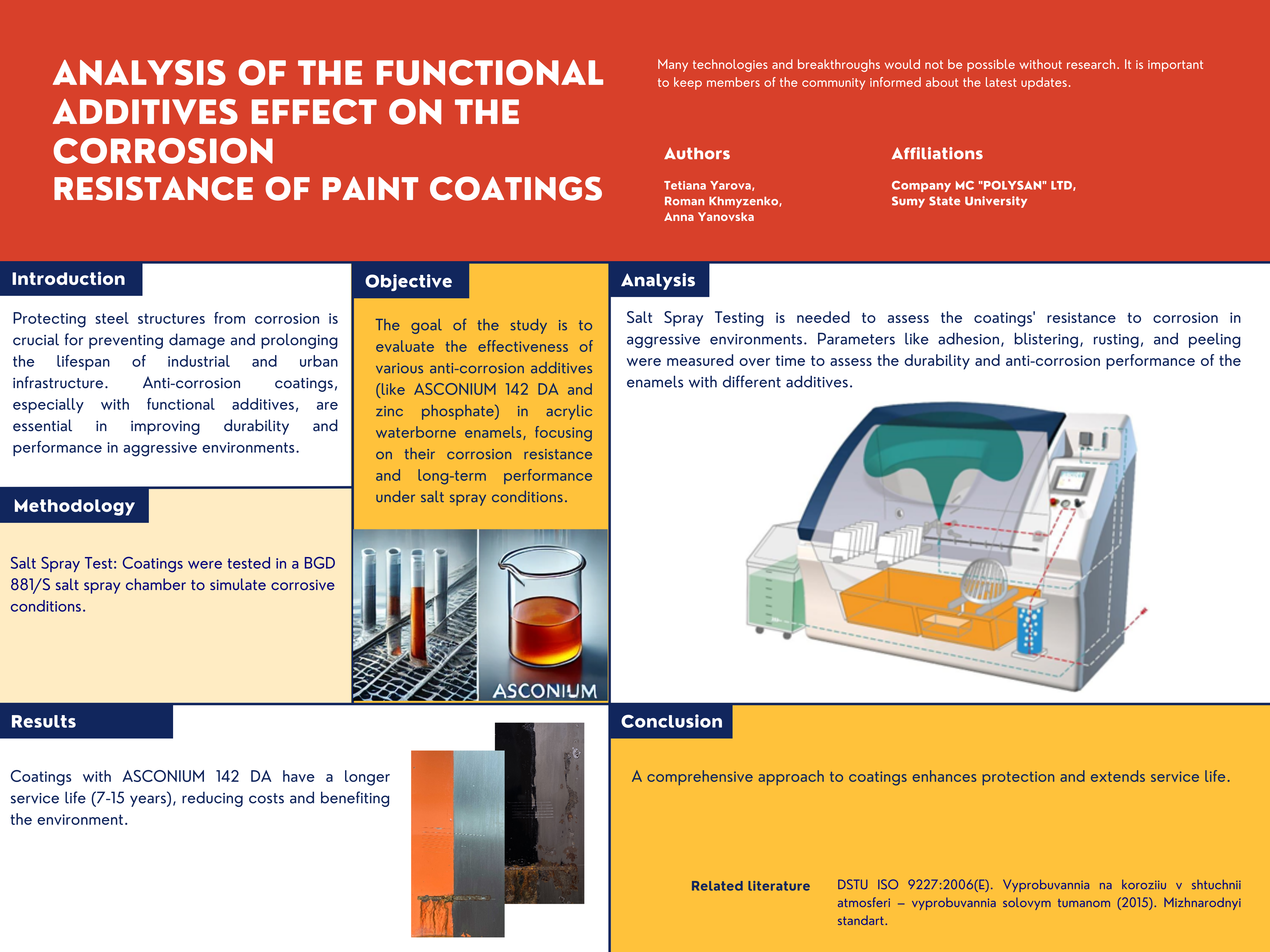

The paper deals with the issue of protecting metals from corrosion, which can damage their structures. Anti-corrosion coatings are widely used to ensure the durability of steel structures. It was described that the durability of the coating depends on the chemical and physical characteristics of the system, such as the type of coating, dry film thickness, water resistance, and adhesion. The importance of artificial aging tests for assessing the durability of coatings is considered, emphasizing that the results of such tests should be interpreted with caution, taking in consideration that artificial aging may not have the same effect as natural exposure. Various anti-corrosion additives for acrylic water-dispersion enamels are also described, which can improve the corrosion resistance of the coating, depending on the service conditions. The object of the research is the properties of enamels with functional additives in salt fog. The study results of the effectiveness of the anti-corrosion additives in acrylic enamels using salt fog from the BGD 881/S chamber are discussed. The research showed that the main requirement for increasing the effectiveness of the anti-corrosion additive in acrylic LPM is a comprehensive approach to improvement of the coating barrier properties, which additionally reduces the aggressive influence of the environment. The advantages of new complex anti-corrosion additives compared to traditional anti-corrosion pigments are multifunctionality – complex additives like Askonium 142 DA contain several active components that affect various coating properties, including anti-corrosion protection, adhesion, and water resistance. Traditional pigments, such as zinc phosphate, usually have only one function – to create a protective film on the metal. The main research idea of the article is to study the influence of anti-corrosion additives in paint coatings for metal protection from corrosion and the extension of the service life of structures.

Supporting Agency

- The study was carried out with the financial support of MC «POLYSAN» LTD.

References

- DSTU ISO 12944-2:2017. Lakofarbovi materialy. Zakhyst metalokonstruktsii vid korozii zakhysnymy lakofarbovymy systemamy. Chastyna 2: Klasyfikatsiia zasobiv masovoi informatsii (2020). Kyiv: DP «UkrNDNTs», 22.

- Nenastyna, T. A., Ved, M. V., Ziubanova, S. I., Proskurina, V. O. (2019). Elektrokhimichne osadzhennia pokryttiv Co-Mo-W ta Co-Mo-Zr zi skladnykh elektrolitiv. Perspektyvni materialy ta protsesy v prykladnii elektrokhimii. Kyiv: KNUTD, 60–66.

- Pavlenko, V., Manuylov, V., Kuzhel, V., Semenchenko, S., Hapula, V. (2023). Research on testing methods for the corrosion resistance of paint coatings. Journal of Mechanical Engineering and Transport, 18 (2), 127–133. https://doi.org/10.31649/2413-4503-2023-18-2-127-133

- Ivanov, S. V., Tytova, S. V., Trachevskyi, V. V., Hrushak, Z. V. (2019). Kontrol yakosti lakofarbovykh materialiv. Kyiv: NAU, 452.

- DSTU ISO 12944-6:2018. Lakofarbovi materialy. Zakhyst metalokonstruktsii vid korozii zakhysnymy lakofarbovymy systemamy. Chastyna 6: Laboratorni metody vyprobuvan (2020). Kyiv: DP «UkrNDNTs», 25.

- Understanding corrosion and salt spray (2016). Available at: https://www.pfonline.com/articles/understanding-corrosion-and-salt-spray

- DSTU ISO 9227:2006(E). Vyprobuvannia na koroziiu v shtuchnii atmosferi – vyprobuvannia solovym tumanom (2015). Mizhnarodnyi standart.

- Programmable Salt Spray (Fog) Cabinets. Biuged laboratory instruments. Available at: https://www.biuged.com/En_Pr_d_gci_124_id_8.html

- Asconium 142DA in Waterborne Direct-To-Metal system. Ascotec. Available at: https://www.ascotran.com/asconium-142da-in-waterborne-direct-to-metal-system/

- DSTU ISO 4628-1:2015. Lakofarbovi materialy. Otsinka poshkodzhennia lakofarbovoho pokryttia. Vyznachennia kilkosti, rozmiru defektiv ta intensyvnosti rivnomirnykh zmin zovnishnoho vyhliadu. Chastyna 1: Osnovni pryntsypy ta systema otsiniuvannia (2015). Kyiv: Ministerstvo ekonomichnoho rozvytku i torhivli Ukrainy, 5.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Tetiana Yarova, Roman Khmyzenko, Anna Yanovska

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.