Determination of the possibility of using a functional apparatus for the production of multi-component semi-finished products with a high degree of readiness

DOI:

https://doi.org/10.15587/2706-5448.2024.314422Keywords:

functional apparatus, vegetable multi-component semi-finished products, combined heat and mass exchange processing, drying in the field of infrared heatingAbstract

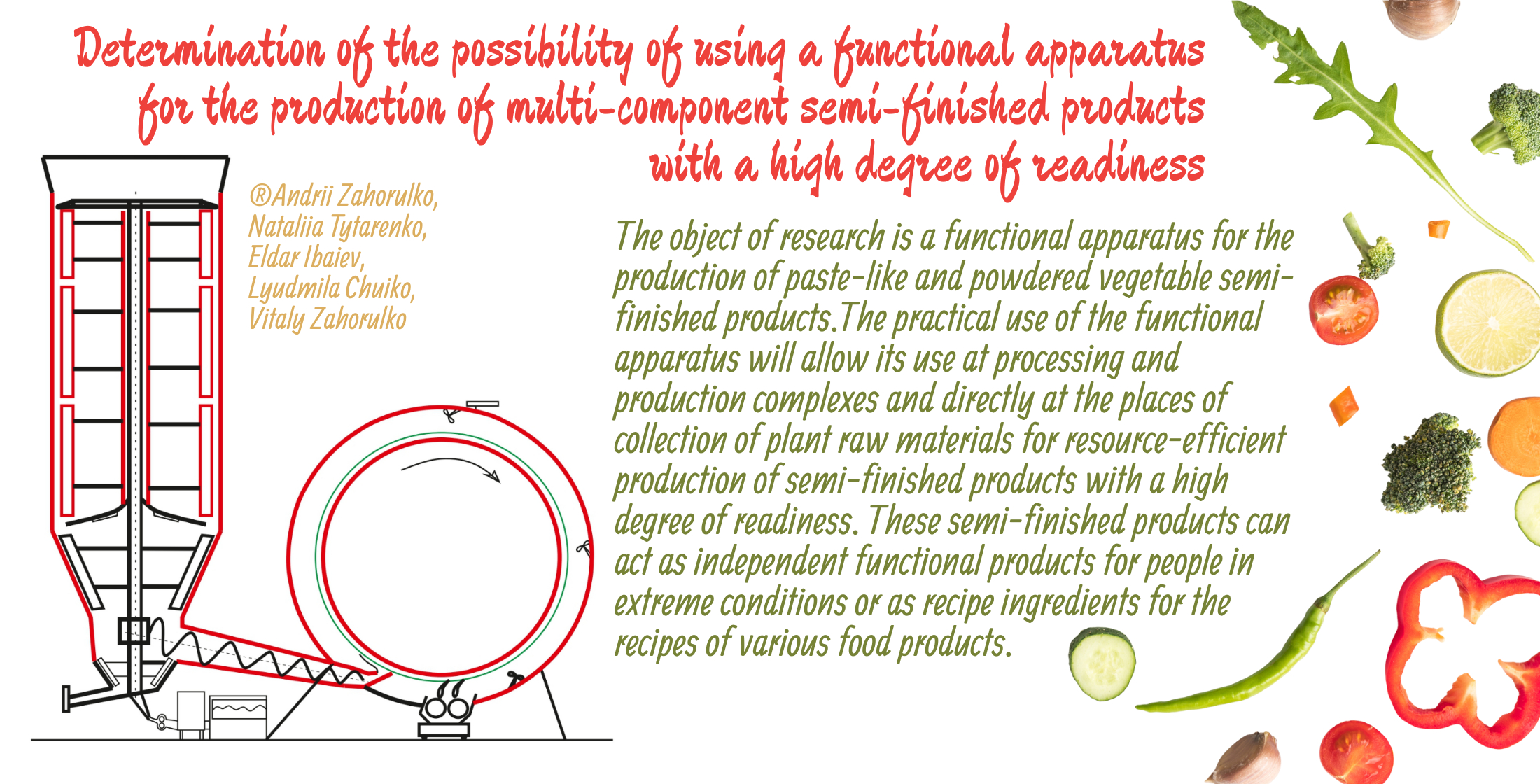

The object of research is a functional apparatus for the production of paste-like and powdered vegetable semi-finished products. The problem of combined heat and mass exchange treatment of vegetable raw materials are solved by using a functional apparatus for concentration and drying for processing and production complexes, farm lands. The expected effect during the approbation of the device is predicted under the condition of a functional approach combining the processes of concentration and drying with precise control of the temperature regime due to the use of a film-like resistive electronic heater of the radiating type.

In the study, the approbation of a functional device for the production of multi-component vegetable semi-finished products of a high degree of readiness, with concentration and drying in the field of infrared heating at a temperature of 50 °C, was performed. Real-time temperature measurement was carried out by an automatic unit based on TRM, which ensured the accuracy of control at each stage. The temperature of the mashed mass during processing increased from 20.3 °С to 23.2 °С, reaching optimal conditions for forming a film with a thickness of 0.5 mm. In the rotary reboiler, the temperature in height varied from 25.7 °C to 50.1 °C, which contributed to the preservation of the properties of thermolabile raw materials. In the lower part of the apparatus, the temperature of the finished product was 49.8 °C, maintaining the necessary temperature regime for drying. The device creates a convective air flow (0.01 m/s) with the help of Peltier elements, which stabilizes the heat exchange at a temperature of 51.3 °C on the technical partition.

The practical use of the functional apparatus will allow its use at processing and production complexes and directly at the places of collection of plant raw materials for resource-efficient production of semi-finished products with a high degree of readiness. These semi-finished products can act as independent functional products for people in extreme conditions or as recipe ingredients for the recipes of various food products.

Supporting Agency

- The work was carried out within the framework of the state budget topic of the project of young scientists No. 1-24-25 BO «Development of hardware and technological solutions for the production of multi-purpose multi-component organic semi-finished products and food products in the conditions of military operations and post-war reconstruction of the country».

References

- Galanakis, C. M., Rizou, M., Aldawoud, T. M. S., Ucak, I., Rowan, N. J. (2021). Innovations and technology disruptions in the food sector within the COVID-19 pandemic and post-lockdown era. Trends in Food Science & Technology, 110, 193–200. https://doi.org/10.1016/j.tifs.2021.02.002

- Munekata, P. E. S., Pérez-Álvarez, J. Á., Pateiro, M., Viuda-Matos, M., Fernández-López, J., Lorenzo, J. M. (2021). Satiety from healthier and functional foods. Trends in Food Science & Technology, 113, 397–410. https://doi.org/10.1016/j.tifs.2021.05.025

- Pap, N., Fidelis, M., Azevedo, L., do Carmo, M. A. V., Wang, D., Mocan, A. et al. (2021). Berry polyphenols and human health: evidence of antioxidant, anti-inflammatory, microbiota modulation, and cell-protecting effects. Current Opinion in Food Science, 42, 167–186. https://doi.org/10.1016/j.cofs.2021.06.003

- Piyush, Kumar, R., Kumar, R. (2020). 3D printing of food materials: A state of art review and future applications. Materials Today: Proceedings, 33, 1463–1467. https://doi.org/10.1016/j.matpr.2020.02.005

- Neamah, H. A., Tandio, J. (2024). Towards the development of foods 3D printer: Trends and technologies for foods printing. Heliyon, 10 (13), e33882. https://doi.org/10.1016/j.heliyon.2024.e33882

- Hubbermann, E. M.; Carle, R., Schweiggert, R. M. (Eds.) (2016). Coloring of Low-Moisture and Gelatinized Food Products. Handbook on Natural Pigments in Food and Beverages. Woodhead Publishing, 179–196. https://doi.org/10.1016/b978-0-08-100371-8.00008-7

- Ruiz Rodríguez, L. G., Zamora Gasga, V. M., Pescuma, M., Van Nieuwenhove, C., Mozzi, F., Sánchez Burgos, J. A. (2021). Fruits and fruit by-products as sources of bioactive compounds. Benefits and trends of lactic acid fermentation in the development of novel fruit-based functional beverages. Food Research International, 140, 109854. https://doi.org/10.1016/j.foodres.2020.109854

- Luzardo-Ocampo, I., Ramírez-Jiménez, A. K., Yañez, J., Mojica, L., Luna-Vital, D. A. (2021). Technological Applications of Natural Colorants in Food Systems: A Review. Foods, 10 (3), 634. https://doi.org/10.3390/foods10030634

- Mykhailov, V., Zahorulko, A., Zagorulko, A., Liashenko, B., Dudnyk, S. (2021). Method for producing fruit paste using innovative equipment. Acta Innovations, 39, 15–21. https://doi.org/10.32933/actainnovations.39.2

- Zahorulko, A. M., Zahorulko, O. Ye. (2016). Pat. No. 108041 UA. Hnuchkyi plivkovyi rezystyvnyi elektronahrivach vyprominiuiuchoho typu. MKP G05D 23/19, B01D 1/22, H05B 3/36. No. u201600827; declareted: 02.20.2016; published: 24.06.2016, Bul. No. 12, 4. Available at: http://uapatents.com/5-108041-gnuchkijj-plivkovijj-rezistivnijj-elektronagrivach-viprominyuyuchogo-tipu.html

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Andrii Zahorulko, Nataliia Tytarenko, Eldar Ibaiev, Lyudmila Chuiko, Vitaly Zahorulko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.