Implementation of block artificial cooling units for gas preparation

DOI:

https://doi.org/10.15587/2706-5448.2024.317589Keywords:

block artificial cooling units, low-temperature separation, unit performance, gas recoveryAbstract

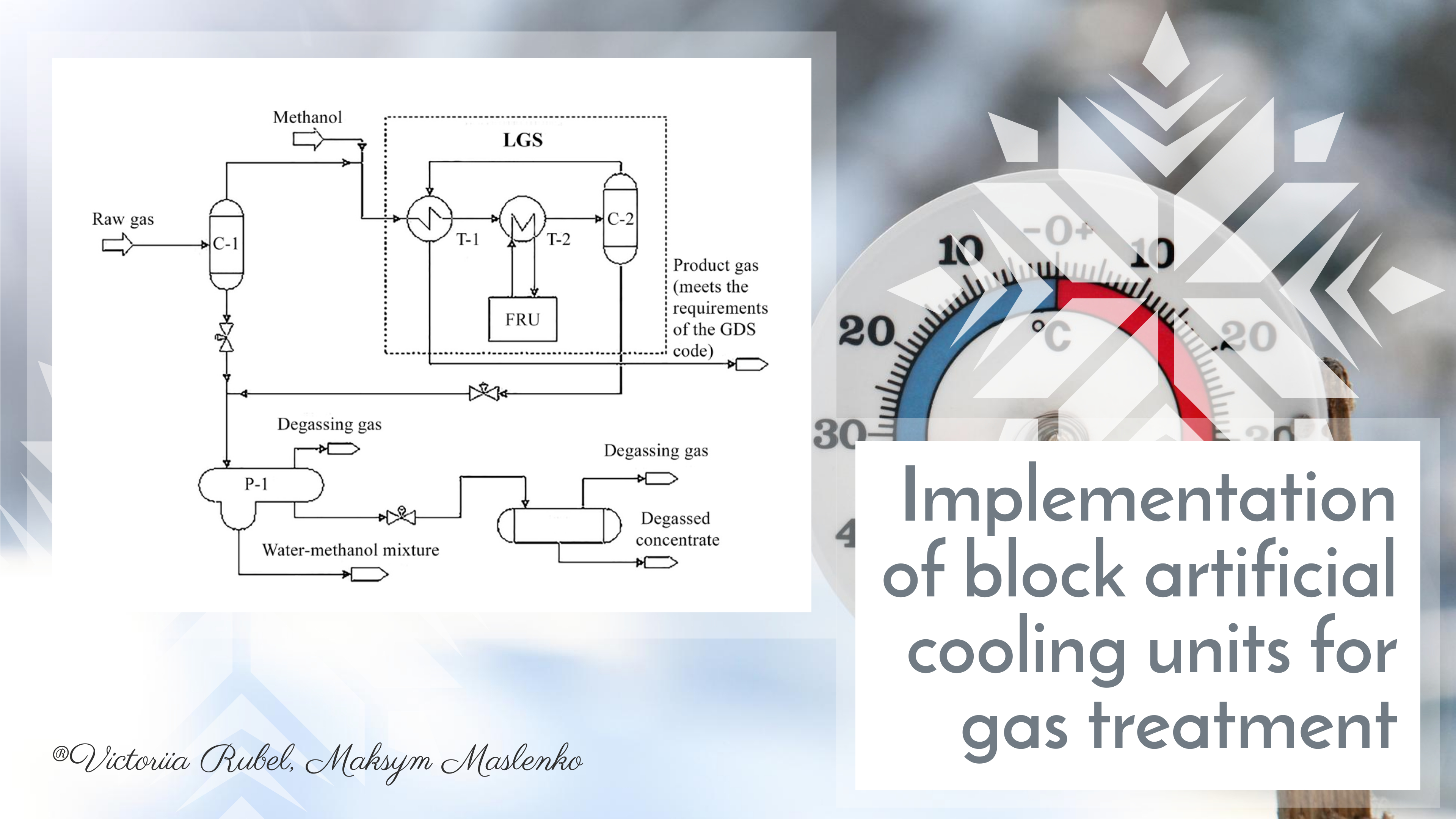

The object of research is the process of implementation and use of block artificial cooling units in the technology of natural gas preparation.

The research has confirmed the high efficiency of using artificial cooling units. Due to deep gas cooling, it is possible to achieve a significant increase in condensate production and improve gas quality. In addition, modern units are characterized by high energy efficiency and compactness.

A comprehensive analysis of existing gas preparation technologies and a comparative assessment using block artificial cooling units revealed a number of significant advantages of the proposed system, namely:

– block units provide deeper removal of heavy hydrocarbons, water and other impurities, which improves the quality of the final product;

– due to lower gas temperature, more intensive condensation of heavy hydrocarbons is achieved, which leads to additional extraction of valuable components;

– modern block units are equipped with energy-efficient equipment, which reduces energy costs;

– the units have a modular design, which facilitates their transportation, unit and maintenance;

– the use of block units allows to reduce emissions of harmful substances into the atmosphere;

– the ability to adapt to different operating conditions and product quality requirements.

The study found that existing natural gas preparation technologies have a number of disadvantages, such as:

– low efficiency of gas purification;

– high energy consumption;

– complexity of maintenance;

– large dimensions of the equipment.

Despite some drawbacks, the introduction of block artificial cooling units is a promising direction for the development of the gas industry. The results of the study indicate the high efficiency of this technology and its economic feasibility in the long term.

References

- Maliarenko, V. A., Senetskyi, O. V. (2021). Teplomasoobmin v obiektakh alternatyvnoi enerhetyky. Kharkiv: KhNUMH im. O. M. Beketova, 311.

- Pro zatverdzhennia Kodeksu hazorozpodilnykh system (2015). Postanova Natsionalnoi komisii, shcho zdiisniuie derzhavne rehuliuvannia u sferakh enerhetyky ta komunalnykh posluh No. 2494. 30.09.2015. Available at: https://zakon.rada.gov.ua/laws/show/z1379-15#Text

- Asadullah, M. (2014). Biomass gasification gas cleaning for downstream applications: A comparative critical review. Renewable and Sustainable Energy Reviews, 40, 118–132. https://doi.org/10.1016/j.rser.2014.07.132

- Koyuncu, I., Yilmaz, C., Alcin, M., Tuna, M. (2020). Design and implementation of hydrogen economy using artificial neural network on field programmable gate array. International Journal of Hydrogen Energy, 45 (41), 20709–20720. https://doi.org/10.1016/j.ijhydene.2020.05.181

- Kopyscinski, J., Schildhauer, T. J., Biollaz, S. M. A. (2010). Production of synthetic natural gas (SNG) from coal and dry biomass – A technology review from 1950 to 2009. Fuel, 89 (8), 1763–1783. https://doi.org/10.1016/j.fuel.2010.01.027

- Akolaş, H. İ., Kaleli, A., Bakirci, K. (2020). Design and implementation of an autonomous EGR cooling system using deep neural network prediction to reduce NOx emission and fuel consumption of diesel engine. Neural Computing and Applications, 33 (5), 1655–1670. https://doi.org/10.1007/s00521-020-05104-1

- Shao, G., Hanaor, D. A. H., Shen, X., Gurlo, A. (2020). Freeze Casting: From Low‐Dimensional Building Blocks to Aligned Porous Structures – A Review of Novel Materials, Methods, and Applications. Advanced Materials, 32 (17). https://doi.org/10.1002/adma.201907176

- Petruniak, M., Rubel, V., Chevhanova, V., Kulakova, S. (2021). Application of grout slurries with the defecate addition for effective well cementing. Mining of Mineral Deposits, 15 (1), 59–65. https://doi.org/10.33271/mining15.01.059

- Wan, K., Barnaud, C., Vervisch, L., Domingo, P. (2020). Chemistry reduction using machine learning trained from non-premixed micro-mixing modeling: Application to DNS of a syngas turbulent oxy-flame with side-wall effects. Combustion and Flame, 220, 119–129. https://doi.org/10.1016/j.combustflame.2020.06.008

- Hadian, M., Saryazdi, S. M. E., Mohammadzadeh, A., Babaei, M. (2021). Application of artificial intelligence in modeling, control, and fault diagnosis. Applications of Artificial Intelligence in Process Systems Engineering. Elsevier, 255–323. https://doi.org/10.1016/b978-0-12-821092-5.00006-1

- Shevchuk, L. V. (2020). Quality management of business processes in the supply chain of refrigeration equipment. Natsionalnyi Aviatsiinyi Universytet. Available at: https://er.nau.edu.ua/handle/NAU/45524

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Victoriia Rubel, Maksym Maslenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.