Influence of mineral filler on the thermal conductivity of polymer composites

DOI:

https://doi.org/10.15587/2706-5448.2024.317659Keywords:

polymer composites, composite thermal conductivity, mineral fillers, fly ash, andesite, Nielsen modelAbstract

The study focuses on the development of polymer composites based on the Latex 2012 aqueous dispersion with mineral fillers of volcanic (andesite) and technogenic (fly ash from Burshtyn TPP and Kurakhove TPP) origin, aimed at achieving optimal thermal insulation properties. The main problem addressed was determining the influence of the type, concentration, and combination of fillers on the thermal conductivity of composites. High thermal conductivity of polymeric materials significantly limits their application in thermal insulation systems, making it crucial to investigate the mechanisms of interfacial interactions between fillers and the matrix for creating effective compositions.

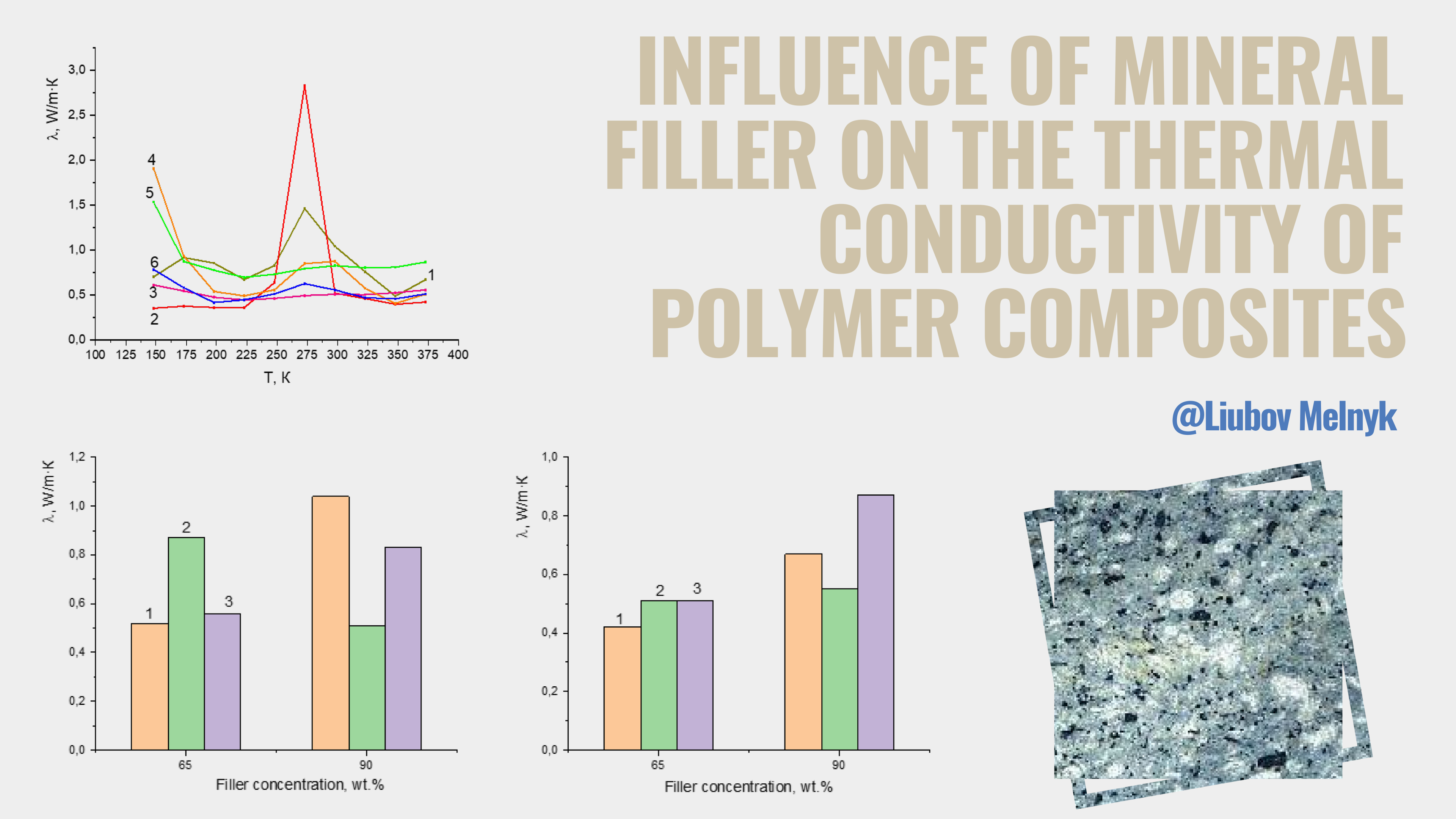

The sizes of filler crystallites were determined using the Scherrer method: for andesite – 110 nm, fly ash B – 100.4 nm, and fly ash K – 113 nm. These data indicate the fillers' ability to affect phonon scattering in the material, reducing overall thermal conductivity. The thermal conductivity of the fillers is as follows: fly ash B – 0.2072 W/m·K, fly ash K – 0.2241 W/m·K, and andesite – 0.2118 W/m·K. Fly ash B demonstrated the best results due to its low thermal conductivity and high surface energy, which contributes to better interaction with the polymer matrix.

An analysis of the dependence of composite thermal conductivity on temperature and filler concentration showed that increasing filler concentration increases thermal conductivity due to the formation of thermal bridges between particles. However, combining different fillers in optimal proportions can mitigate this effect. Based on the Nielsen model, the composite compositions were optimized to achieve minimum thermal conductivity. The best results were obtained for a binary filler system of fly ash B and andesite in a 53:35 mass ratio, providing the lowest effective thermal conductivity of the composite – 0.173 W/m·K. Other successful combinations include fly ash B with fly ash K (60:40 wt. %) and andesite with fly ash K (45:55 wt. %), which also demonstrate significant improvements in thermal insulation properties.

The proposed compositions can be applied in the field of energy-efficient construction, thermal regulation systems, thermal insulation materials for industrial equipment, and other areas requiring low thermal conductivity. The research results are also valuable for developing materials that operate under significant temperature variations (from –125 °C to +100 °C), providing stable thermal insulation properties.

References

- Dіnzhos, R. V., Fіalko, N. M., Lysenko, E. A. (2014). Analysis of thermal conductivity of polymer nanocomposites filled with carbon nanotubes and technical carbon. Journal of Nano- and Electronic Physics, 6, 01015.

- Kurta, S. A. (2012). Napovniuvachi – syntez, vlastyvosti ta vykorystannia. Ivano-Frankivsk: Vyd-vo Prykarpat. Nat. Univ. named after V. Stefanyk, 296.

- Lazarenko, A., Vovchenko, L., Prylutskyy, Y., Matzuy, L., Ritter, U., Scharff, P. (2009). Mechanism of thermal and electrical conductivity in polymer‐nanocarbon composites. Materialwissenschaft Und Werkstofftechnik, 40 (4), 268–272. https://doi.org/10.1002/mawe.200900439

- Mamunya, Ye. P., Levchenko, V. V., Parashchenko, I. M., Lebedev, E. V. (2016). Thermal and electrical conductivity of the polymer-metal composites with 1D structure of filler formed in a magnetic field. Polymer Journal, 38 (1), 3–17. https://doi.org/10.15407/polymerj.38.01.003

- Heap, M. J., Alizada, G., Jessop, D. E., Kennedy, B. M., Wadsworth, F. B. (2024). The influence of temperature (up to 120 °C) on the thermal conductivity of variably porous andesite. Journal of Volcanology and Geothermal Research, 452, 108140. https://doi.org/10.1016/j.jvolgeores.2024.108140

- Wang, Q., Wang, D., Chen, H. (2017). The role of fly ash microsphere in the microstructure and macroscopic properties of high-strength concrete. Cement and Concrete Composites, 83, 125–137. https://doi.org/10.1016/j.cemconcomp.2017.07.021

- Mironyuk, I. F., Tatarchuk, T. R., Vasylyeva, H. V., Yaremiy, I. P., Mykytyn, I. M. (2019). Morphology, phase composition and radiological properties of fly ash obtained from the Burshtyn thermal power plant. Physics and Chemistry of Solid State, 19 (2), 171–178. https://doi.org/10.15330/pcss.19.2.171-178

- Wasekar, P. A., Kadam, P. G., Mhaske, S. T. (2012). Effect of Cenosphere Concentration on the Mechanical, Thermal, Rheological and Morphological Properties of Nylon 6. Journal of Minerals and Materials Characterization and Engineering, 11 (8), 807–812. https://doi.org/10.4236/jmmce.2012.118070

- Melnyk, L. I., Cherniak, L. P., Yevpak, V. V. (2024). Composites based on fly ash with different polymer matrixes. Scientific Notes of Taurida National V. I. Vernadsky University. Series: Technical Sciences, 2 (1), 106–112. https://doi.org/10.32782/2663-5941/2024.1.2/18

- Blake, A. J., Clegg, W. (2009). Crystal Structure Analysis. Principles and Practice. International Union of Crystallography. Oxford University Press, 251–263.

- Melnyk, L. (2024). Formation of composite with variation of dispersity of filler and type of binder. Technical sciences and technologies, 1 (35), 198–203. https://doi.org/10.25140/2411-5363-2024-1(35)-198-203

- Nielsen, L. E. (1974). The Thermal and Electrical Conductivity of Two-Phase Systems. Industrial & Engineering Chemistry Fundamentals, 13 (1), 17–20. https://doi.org/10.1021/i160049a004

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Liubov Melnyk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.