Development and research of energy-efficient helio-air collectors for drying agricultural products

DOI:

https://doi.org/10.15587/2706-5448.2024.318480Keywords:

solar radiation, heliocollector, drying agent – air, heat transfer, film sleeves, solar absorberAbstract

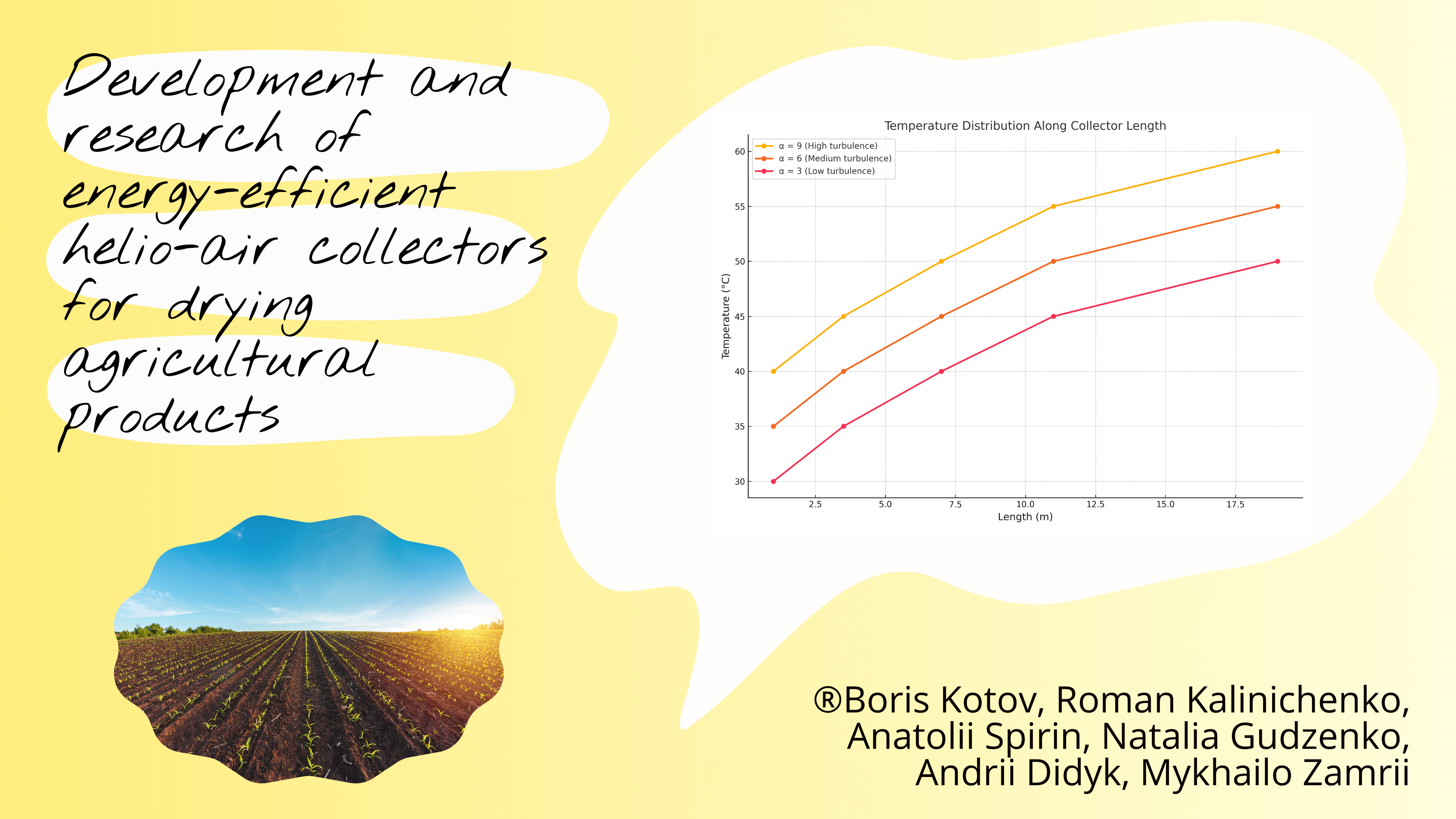

The object of study is the drying of agricultural plant products. Artificial heat drying of agricultural plant products (seeds, fruits, nuts, grain, etc.), as a traditional method of canning and preparation for storage and further processing, usually takes place in dryers of seasonal use. To reduce the consumption of traditional types of organic fuel, it is proposed to use a lightweight portable film solar collector to heat the drying agent in seasonal dryers. A mathematical description of thermal processes in a solar collector is given. To increase the efficiency (degree of air heating), devices are proposed – heat exchange intensifiers. Effective methods of increasing the thermal power of the solar collector based on the use of ring and spiral turbolyzers of the coolant flow and sectional multi-pipe (multi-element) absorber have been theoretically substantiated, experimentally confirmed. The use of these structural elements of the solar collector will increase the thermal performance per unit area of the solar radiation absorber, which will increase the heating of the blunt carrier with 26 °С before 32 °C for tube absorbers and up to 36 °C for sectional absorbers. Maximum specific power of the solar collector with an area 240 m2 – 0.2 kW/m2 with a specific flow rate of the coolant of 23 m3/h·m2. For systems of active ventilation of seed material with specific air flow rates up to 100 m3/h·m2, it is possible to heat the atmospheric air up to 10 °C, which ensures round-the-clock drying of the product. A simplified mathematical model is formulated to intensify parameters according to the data of experiments. The heat transfer coefficients from the film absorber of solar energy to the heated air are determined. The results of the experimental determination of the thermal characteristics of the solar collector and its energy efficiency are presented. As the calculations showed, a further increase in the performance of the tubular solar collector is possible with an increase in the flow rate in the film absorber, which can be realized by reducing the diameter of the pipeline.

References

- Jahan, A. (2021). A Study on Urbanization and the Associated Challenges. International Journal of Innovative Research in Engineering and Management, 8 (6), 457–461.

- Torshizi, M. V., Mighani, A. H. (2017). The application of solar energy in agricultural systems. Renewable Energy and Sustainable Development, 3 (2), 234–240. https://doi.org/10.21622/resd.2017.03.2.234

- Korobka, S. V. (2013). Issledovanie parametrov i rezhimov raboty konvektivnoi geliosushilki fruktov. MOTROL. Commisssion of motorization and energetics in agriculture, 15 (4), 134–139.

- Korobka, S. (2014). Study researches solar-radiation-convection drying method drying stone fruit in convective gelioмdryers. MOTROL. Commisssion of motorization and energetics in agriculture, 16 (4), 112–116. Available at: https://www.pan-ol.lublin.pl/archiwum/wydawnictwa/Motrol16_4_2014.html

- Klymchuk, V. M. (2000). Sushinnia lnovorokhu z kompleksnym vykorystanniam soniachnoi ta elektrychnoi enerhii. Mekhanizatsiia ta elektryfikatsiia silskoho hospodarstva, 83, 125–126.

- Klymchuk, V. M. (2003). Vykorystannia soniachnoi enerhii pry sushinni zerna. Mekhanizatsiia ta elektryfikatsiia silskoho hospodarstva, 87, 117–120.

- Burnaiev, M. O. (2001). Doslidzhennia roboty heliokolektora dlia pidihrivu povitria pry aktyvnomu vysushuvanni sina. Netradytsiini ta ponovliuvani dzherela enerhii yak alternatyvni pervynnym dzherelam enerhii v rehioni. Lviv, 159–163.

- Doroshenko, A., Glauberman, M. (2012). Alternative Energy. Refrigerating and Heating Systems. Odessa: ONU, 447.

- Babych, M., Krygul, R., Shapoval, S., Tolstushko, N., Korobka, S., Tolstushko, M. (2019). Results of experimental researches into process of oak veneer drying in the solar dryer. Eastern-European Journal of Enterprise Technologies, 2 (8 (98)), 13–22. https://doi.org/10.15587/1729-4061.2019.162948

- Rafizul, I. M., Alamgir, M., Shahed Sharif, S. M. (2012). Analysis and Selection of Appropriate Aggregation Function for Calculating of Leachate Pollution Index of Landfill Lysimeter. Iranica Journal of Energy and Environment, 3 (4), 371–380. https://doi.org/10.5829/idosi.ijee.2012.03.04.11

- Klymchuk, V. M., Andrianov, A. I. (2000). Doslidzhennia roboty trubchastoho soniachnoho kolektora. Mekhanizatsiia ta elektryfikatsiia silskoho hospodarstva, 88, 170–174.

- Korobka, S., Babych, M., Krygul, R., Tolstushko, N., Tolstushko, M. (2017). Research into technological process of convective fruit drying in a solar dryer. Eastern-European Journal of Enterprise Technologies, 3 (8 (87)), 55–63. https://doi.org/10.15587/1729-4061.2017.103846

- AI-Neama, M., Farkas, I. (2018). Utilization of Solar Air Collectors for Product's Drying Processes. The Journal of Scientific and Engineering Research, 5 (2), 40–56.

- Zhelykh, V., Kozak, K., Dzeryn, O., Pashkevych, V. (2018). Physical Modeling of Thermal Processes of the Air Solar Collector with Flow Turbulators. Energy Engineering and Control Systems, 4 (1), 9–16. https://doi.org/10.23939/jeecs2018.01.009

- Kotov, B. I. (1994). Tekhnologicheskie i teploenergeticheskie osnovy povysheniia effektivnosti sushki rastitelnogo syria. PhD Thesis.

- Kalinin, E., Dreitser, G., Yarkho, S. (1972). Intensifikatciia teploobmena v kanalakh. Mashinostroenie, 220.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Boris Kotov, Roman Kalinichenko, Anatolii Spirin, Natalia Gudzenko, Andrii Didyk, Mykhailo Zamrii

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.