Research of methanol content in technological flows of facilities that process gas preparation by low-temperature separation method

DOI:

https://doi.org/10.15587/2706-5448.2024.318926Keywords:

natural gas, associated formation water, inhibitor, gas hydrates, computer modelingAbstract

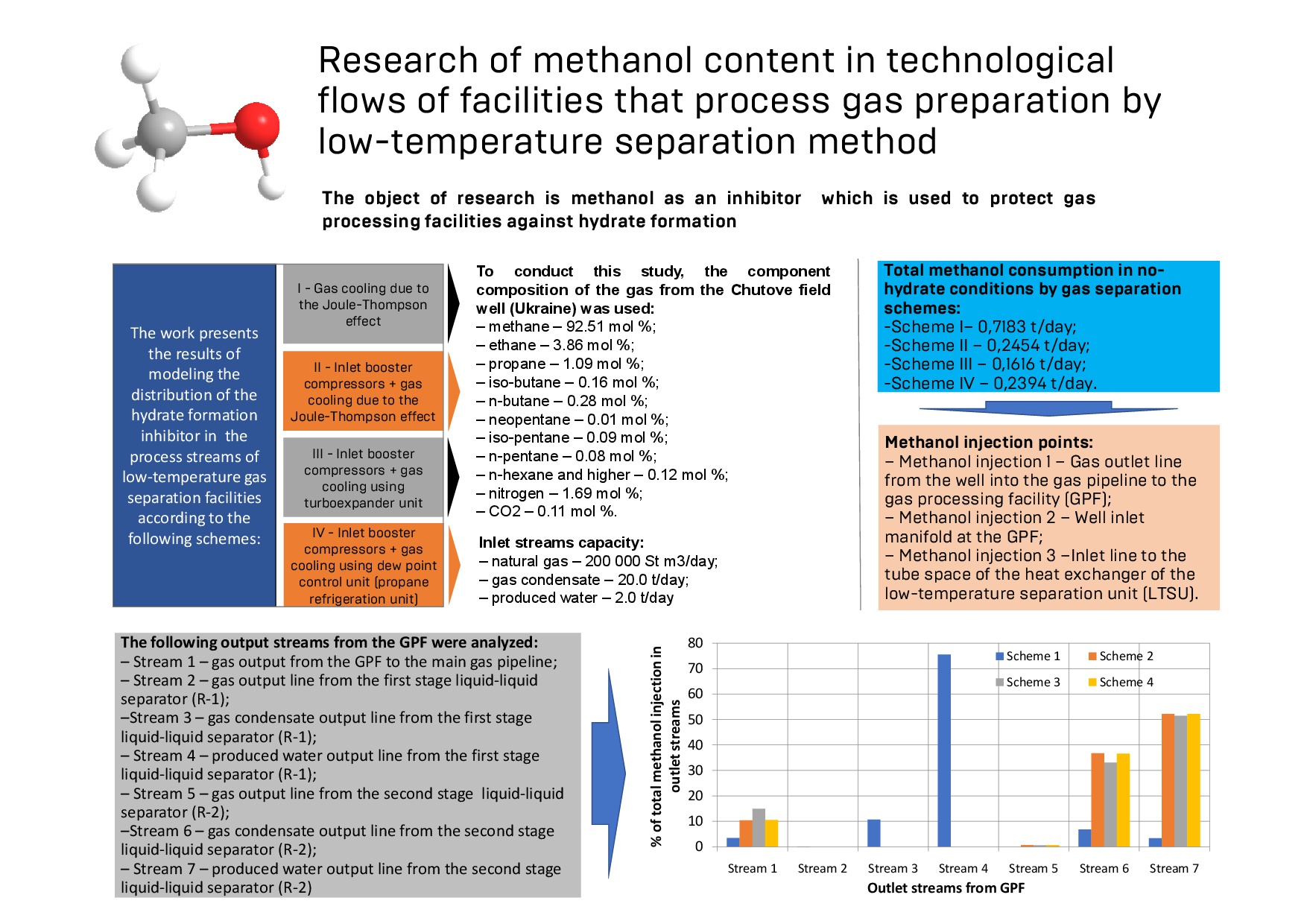

The object of research is methanol as an inhibitor, which is used in the process of collecting and preparing products from gas, gas condensate, and oil fields to protect against hydrate formations. It is important to ensure the rational consumption of this inhibitor, taking into account its solubility in gas, water, and liquid hydrocarbons. This work is aimed at analyzing the use of the methanol hydrate formation inhibitor in the process of low-temperature gas preparation and determining ways to use it more effectively.

The work presents the results of modeling the distribution of the hydrate formation inhibitor along the technological flows of low-temperature gas separation units according to the following schemes:

– low-temperature separation with gas cooling due to the Joule-Thompson effect;

– compression of gas from wells using PCS (pressure compressor station) + low-temperature separation with gas cooling due to the Joule-Thompson effect;

– compression of gas from wells using PCS + low-temperature separation with gas cooling due to the operation of a turboexpander unit;

– compression of gas from wells using PCS + low-temperature separation with gas cooling due to the operation of an artificial refrigeration unit (propane refrigeration unit).

The use of a computer simulator allowed to track in detail the distribution of methanol during the gas preparation process. The iteration method determined the minimum values of methanol consumption at which the hydrate-free operation mode of the equipment is maintained. Based on the modeling results, an analysis of methanol content in technological flows was performed. And the patterns of inhibitor separation in the separation equipment were also determined, namely, the dependence of methanol distribution on gas pressure in separators, and the methanol content in the output lines of gas preparation units.

It was established that the results of the study can be applied in the development of technologies for the collection, regeneration and reuse of methanol in technological processes of low-temperature gas preparation. The practical value of the results lies in the possibility of improving typical methods of protecting equipment from hydrate formations by developing an automated inhibitor supply system that, by monitoring the parameters of the technological process, changes the inhibitor dosage and ensures its economical use.

References

- Carrol, J. (2020). Natural Gas Hydrates A Guide for Engineers. Elsevier, 184–208. https://doi.org/10.1016/c2019-0-04277-x

- Hu, P., Ke, W., Chen, D. (2022). Molecular Dynamics Simulation of Methane Hydrate Formation on Pipeline Surface in the Presence of Corrosion Inhibitors. Energy & Fuels, 37 (1), 301–309. https://doi.org/10.1021/acs.energyfuels.2c03337

- Samie, N. N. (2016). Systems and Equipment for Offshore Platform Design. Practical Engineering Management of Offshore Oil and Gas Platforms. Cambridge: Gulf Professional Publishing, 213–346. https://doi.org/10.1016/b978-0-12-809331-3.00003-x

- Makwashi, N., Ahmed, T. G. (2021). Gas Hydrate Formation: Impact on Oil and Gas Production and Prevention Strategies. Nigerian Research Journal of Engineering and Environmental Sciences, 6 (1), 61–75. https://doi.org/10.5281/zenodo.5047631

- Micucci, L., Nigi, S. (2021). Natural gas liquids extraction and separation. Gas Processing & LNG, 1/1/2021. Available at: http://gasprocessingnews.com/articles/2021/02/natural-gas-liquids-extraction-and-separation/

- Zhao, J., Lang, C., Chu, J., Yang, L., Zhang, L. (2023). Flow Assurance of Hydrate Risk in Natural Gas/Oil Transportation: State-of-the-Art and Future Challenges. The Journal of Physical Chemistry C, 127 (28), 13439–13450. https://doi.org/10.1021/acs.jpcc.3c02134

- Dmytrenko, V. I., Zezekalo, I. G., Vynnykov, Y. L. (2022). The use of bischofite in the gas industry as an inhibitor of hydrate formation. IOP Conference Series: Earth and Environmental Science, 1049 (1), 012052. https://doi.org/10.1088/1755-1315/1049/1/012052

- Dmytrenko, V., Zezekalo, I., Vynnykov, Y., Manhura, A. (2021). Efficiency evaluation of using highly mineralized reservoir waters for preventing hydrate formation of natural gas in the conditions of Zakhidno-Radchenkivske gas-condensate field. IOP Conference Series: Earth and Environmental Science, 628 (1), 012015. https://doi.org/10.1088/1755-1315/628/1/012015

- Marsetyo, M. M., Suranto, Herianto, Ratnaningsih, D. R., Kristanto, D. (2023). Study of hydrate formation due to the Joule Thomson effect and optimization of methanol (MeOH) injection as a hydrate prevention method. 4TH International Conference on Earth Science, Mineral and Energy, 2598, 030012. https://doi.org/10.1063/5.0126565

- Teixeira, A. M., Arinelli, L. de O., de Medeiros, J. L., Araújo, O. de Q. F. (2018). Recovery of thermodynamic hydrate inhibitors methanol, ethanol and MEG with supersonic separators in offshore natural gas processing. Journal of Natural Gas Science and Engineering, 52, 166–186. https://doi.org/10.1016/j.jngse.2018.01.038

- Lauricella, M., Ghaani, M. R., Nandi, P. K., Meloni, S., Kvamme, B., English, N. J. (2022). Double Life of Methanol: Experimental Studies and Nonequilibrium Molecular-Dynamics Simulation of Methanol Effects on Methane-Hydrate Nucleation. The Journal of Physical Chemistry C, 126 (13), 6075–6081. https://doi.org/10.1021/acs.jpcc.2c00329

- Pandey, J., Khan, S., von Solms, N. (2022). Screening of Low-Dosage Methanol as a Hydrate Promoter. Energies, 15 (18), 6814. https://doi.org/10.3390/en15186814

- Sloan Jr., E. D., Koh, C. A., Koh, C. A. (2007). Clathrate Hydrates of Natural Gases. CRC Press. https://doi.org/10.1201/9781420008494

- Hammerschmidt, E. G. (1934). Formation of Gas Hydrates in Natural Gas Transmission Lines. Industrial & Engineering Chemistry, 26 (8), 851–855. https://doi.org/10.1021/ie50296a010

- Dmytrenko, V. (2009). The influence of surfactants on the conditions of propane hydrate formation. Chemistry and Modern Technologies. Dnipropetrovsk: UDCTU, 43.

- Trevor, R. (2019). Oil and Gas Field Application of Hydrate Kinetics Modeling. Memorial University of Newfoundland. Available at: https://books.google.com.ua/books/about/Oil_and_Gas_Field_Application_of_Hydrate.html?id=ayQxzwEACAAJ&redir_esc=y

- Rebai, N., Hadjadj, A., Benmounah, A., Berrouk, A. S., Boualleg, S. M. (2019). Prediction of natural gas hydrates formation using a combination of thermodynamic and neural network modeling. Journal of Petroleum Science and Engineering, 182, 106270. https://doi.org/10.1016/j.petrol.2019.106270

- Bozorgian, A. (2020). Methods of Predicting Hydrates Formation. Advanced Journal of Science and Engineering, 1 (2), 34–39.

- Toyin Olabisi, O., Chukwuemeka Emmanuel, U. (2019). Simulation of Laboratory Hydrate Loop Using Aspen Hysys. Engineering and Applied Sciences, 4 (3), 52–58. https://doi.org/10.11648/j.eas.20190403.11

- Kaiser, M. J. (2020). The Offshore Pipeline Construction Industry Activity Modeling and Cost Estimation in the U.S Gulf of Mexico. Elsevier. https://doi.org/10.1016/c2019-0-01414-8

- Mokhatab, S., Poe, W. A., Mak, J. Y. (2019). Handbook of Natural Gas Transmission and Processing. Principles and Practices. Elsevier, 133–152. https://doi.org/10.1016/c2017-0-03889-2

- Johannes Fink (2021). Petroleum Engineer's Guide to Oil Field Chemicals and Fluids Third Edition. Elsevier. https://doi.org/10.1016/c2020-0-02705-2

- Kidnay, A. J., Parrish, W. R., McCartney, D. G. (2019). Fundamentals of Natural Gas Processing. Kidnay: CRC Press, 172–178. https://doi.org/10.1201/9780429464942

- Bavoh, C. B., Nashed, O., Rehman, A. N., Othaman, N. A. A. B., Lal, B., Sabil, K. M. (2021). Ionic Liquids as Gas Hydrate Thermodynamic Inhibitors. Industrial & Engineering Chemistry Research, 60 (44), 15835–15873. https://doi.org/10.1021/acs.iecr.1c01401

- Dubey, S., Gurjar, P., Kumar, U., Sahai, M., Kumar, S., Kumar, A. (2023). Elucidating the Impact of Thermodynamic Hydrate Inhibitors and Kinetic Hydrate Inhibitors on a Complex System of Natural Gas Hydrates: Application in Flow Assurance. Energy & Fuels, 37 (9), 6533–6544. https://doi.org/10.1021/acs.energyfuels.3c00430

- Abidin, M. Z. Z., Aman, Z. M., May, E. F., Johns, M. L., Lou, X. (2023). Hydrate dispersion stability in synergistic hydrate inhibition of monoethylene glycol and anti-agglomerants. Chemical Engineering Science, 269, 118462. https://doi.org/10.1016/j.ces.2023.118462

- Chen, L., Merey, S. (2021). Oceanic Methane Hydrates Fundamentals, Technological Innovations, and Sustainability. Elsevier. https://doi.org/10.1016/c2018-0-03857-8

- Zhang, L., Dong, H., Dai, S., Kuang, Y., Yang, L., Wang, J., Zhao, J., Song, Y. (2022). Effects of depressurization on gas production and water performance from excess-gas and excess-water methane hydrate accumulations. Chemical Engineering Journal, 431, 133223. https://doi.org/10.1016/j.cej.2021.133223

- Peng, D.-Y., Robinson, D. B. (1976). A New Two-Constant Equation of State. Industrial & Engineering Chemistry Fundamentals, 15 (1), 59–64. https://doi.org/10.1021/i160057a011

- Okonji, S., Ariavie, G., Egware, H., Kwasi-Effah, C. (2020). Review of Gas Hydrate Plug Dissociation in Oil and Gas Pipeline: Downstream Pressure Reduction Approach. Journal of Science and Technology Research, 2 (1), 182–199.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Viktoriia Dmytrenko, Taras Podoliak

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.