Development of elements of an informational-and-mathematical model of hydrodynamic processes in a ceramic catalytic converter for developing an enterprise computer simulation model

DOI:

https://doi.org/10.15587/2706-5448.2024.319177Keywords:

ceramic catalysts, mathematical modeling, computer simulation model, hydrodynamics, reaction kinetics, CFD modeling, oil refiningAbstract

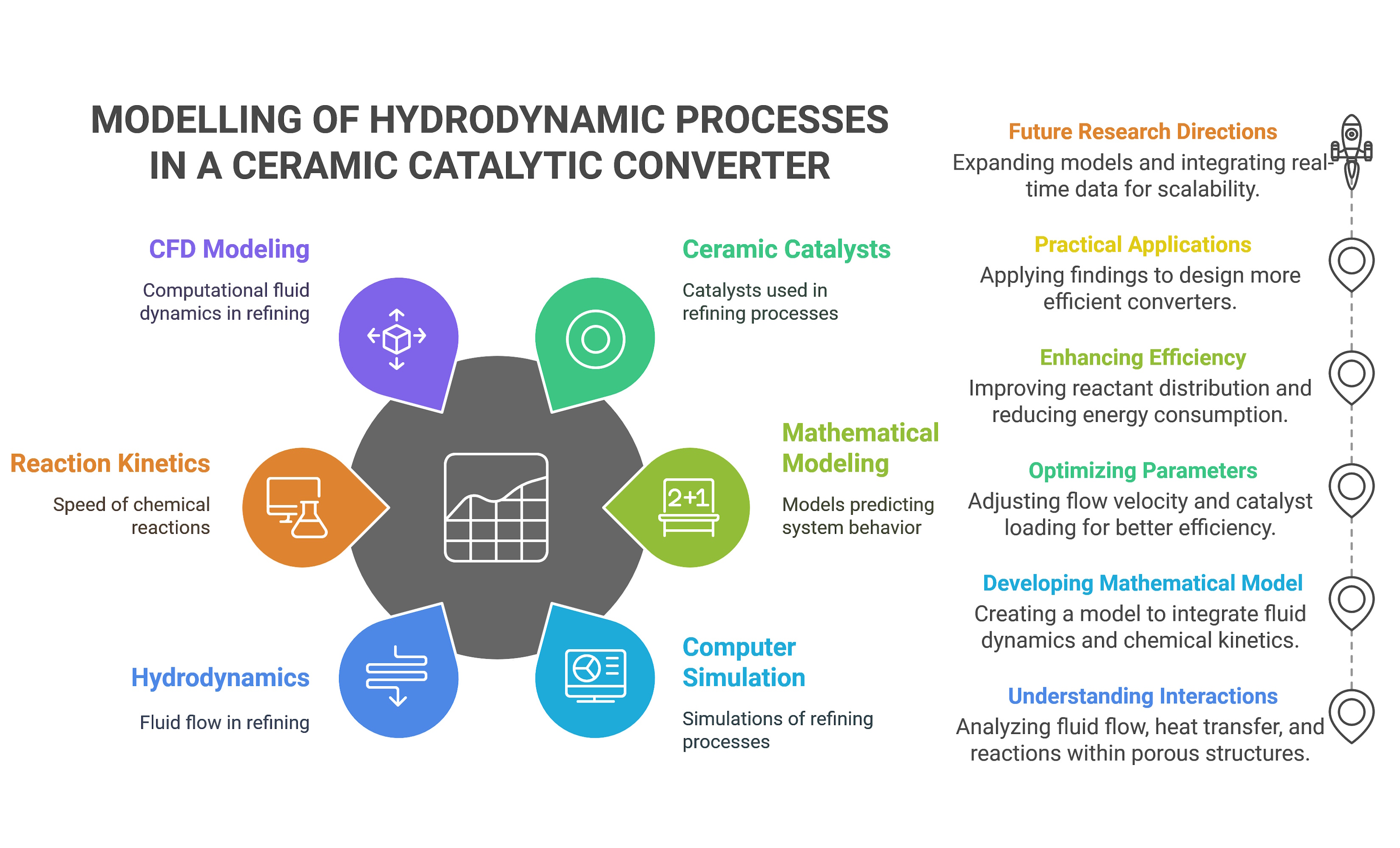

The object of this study is the hydrodynamic processes in ceramic catalytic converters used in high-temperature petroleum refining. This is essential for improving fuel quality and adhering to environmental regulations. The research addresses the optimization of catalytic converter performance by understanding the interactions within their porous ceramic structures, influenced by fluid flow, heat transfer, and chemical reactions. It advocates for computational modeling to simulate these processes more accurately, overcoming the limitations of traditional methods.

The paper is aimed at developing a robust system integrating computational fluid dynamics (CFD) with experimental data to optimize ceramic catalytic converter performance. A mathematical model was created to combine fluid dynamics within the ceramic’s porous structure with the chemical kinetics of catalytic reactions in petroleum refining.

Key findings show that optimizing parameters such as flow velocity and catalyst loading enhances the distribution of reactants across its surface, leading to improved conversion efficiency and reduced energy consumption. The research demonstrates that diffusion and kinetic limitations critically influence catalytic performance. Higher cobalt concentrations in the catalyst layer promoted diffusion-controlled reactions, enhancing efficiency at high flow rates.

The results offer practical applications for the petroleum refining industry, providing a framework to design more efficient catalytic converters. This modeling approach enables engineers to optimize catalytic system designs, improving operational efficiency and compliance with regulatory standards.

Moreover, the study highlights areas for further research, such as expanding the model to include more complex operational conditions and integrating real-time experimental data for better accuracy. This will improve both the design and performance of ceramic catalytic converters in high-temperature refining processes. Future work could also explore scalability for industrial systems, facilitating the integration of optimized catalytic converters into refinery setups to meet performance and environmental standards.

References

- Li, A., Zhang, W., Zhang, X., Chen, G., Liu, X., Jiang, A. et al. (2024). A Deep U-Net-ConvLSTM Framework with Hydrodynamic Model for Basin-Scale Hydrodynamic Prediction. Water, 16 (5), 625. https://doi.org/10.3390/w16050625

- Krychowska, A., Kordas, M., Konopacki, M., Grygorcewicz, B., Musik, D., Wójcik, K. et al. (2020). Mathematical Modeling of Hydrodynamics in Bioreactor by Means of CFD-Based Compartment Model. Processes, 8 (10), 1301. https://doi.org/10.3390/pr8101301

- Akhtar, M. S., Ali, S., Zaman, W. (2024). Recent Advancements in Catalysts for Petroleum Refining. Catalysts, 14 (12), 841. https://doi.org/10.3390/catal14120841

- Ortloff, C. R. (2024). Engineering and Modeling of Water Flow via Computational Fluid Dynamics (CFD) and Modern Hydraulic Analysis Methods. Water, 16 (21), 3086. https://doi.org/10.3390/w16213086

- Yang, L., Liu, F., Saito, K., Liu, K. (2018). CFD Modeling on Hydrodynamic Characteristics of Multiphase Counter-Current Flow in a Structured Packed Bed for Post-Combustion CO2 Capture. Energies, 11 (11), 3103. https://doi.org/10.3390/en11113103

- Al-Ameri, O. B., Alzuhairi, M., Bailón-García, E., Carrasco-Marín, F., Amaro-Gahete, J. (2024). Transforming Petrochemical Processes: Cutting-Edge Advances in Kaolin Catalyst Fabrication. Applied Sciences, 14 (19), 9080. https://doi.org/10.3390/app14199080

- Oloruntoba, A., Zhang, Y., Hsu, C. S. (2022). State-of-the-Art Review of Fluid Catalytic Cracking (FCC) Catalyst Regeneration Intensification Technologies. Energies, 15 (6), 2061. https://doi.org/10.3390/en15062061

- Bagnato, G., Sanna, A., Paone, E., Catizzone, E. (2021). Recent Catalytic Advances in Hydrotreatment Processes of Pyrolysis Bio-Oil. Catalysts, 11 (2), 157. https://doi.org/10.3390/catal11020157

- Robles-Lorite, L., Dorado-Vicente, R., Torres-Jiménez, E., Bombek, G., Lešnik, L. (2023). Recent Advances in the Development of Automotive Catalytic Converters: A Systematic Review. Energies, 16 (18), 6425. https://doi.org/10.3390/en16186425

- Emberru, R. E., Patel, R., Mujtaba, I. M., John, Y. M. (2024). A Review of Catalyst Modification and Process Factors in the Production of Light Olefins from Direct Crude Oil Catalytic Cracking. Sci, 6 (1), 11. https://doi.org/10.3390/sci6010011

- Hayes, R. E., Fadic, A., Mmbaga, J., Najafi, A. (2012). CFD modelling of the automotive catalytic converter. Catalysis Today, 188 (1), 94–105. https://doi.org/10.1016/j.cattod.2012.03.015

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Anton Myronov, Mariia Ilchenko, Yevheniia Ponomarenko, Kostiantyn Gorbunov, Serhii Bykanov, Hanna Ponomarenko, Liudmyla Solovei

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.