Optimization of the concrete production process in terms of energy consumption

DOI:

https://doi.org/10.15587/2706-5448.2024.319827Keywords:

power supply systems, concrete mixing plant, hopper, conveyor, concrete mixture, automation systemAbstract

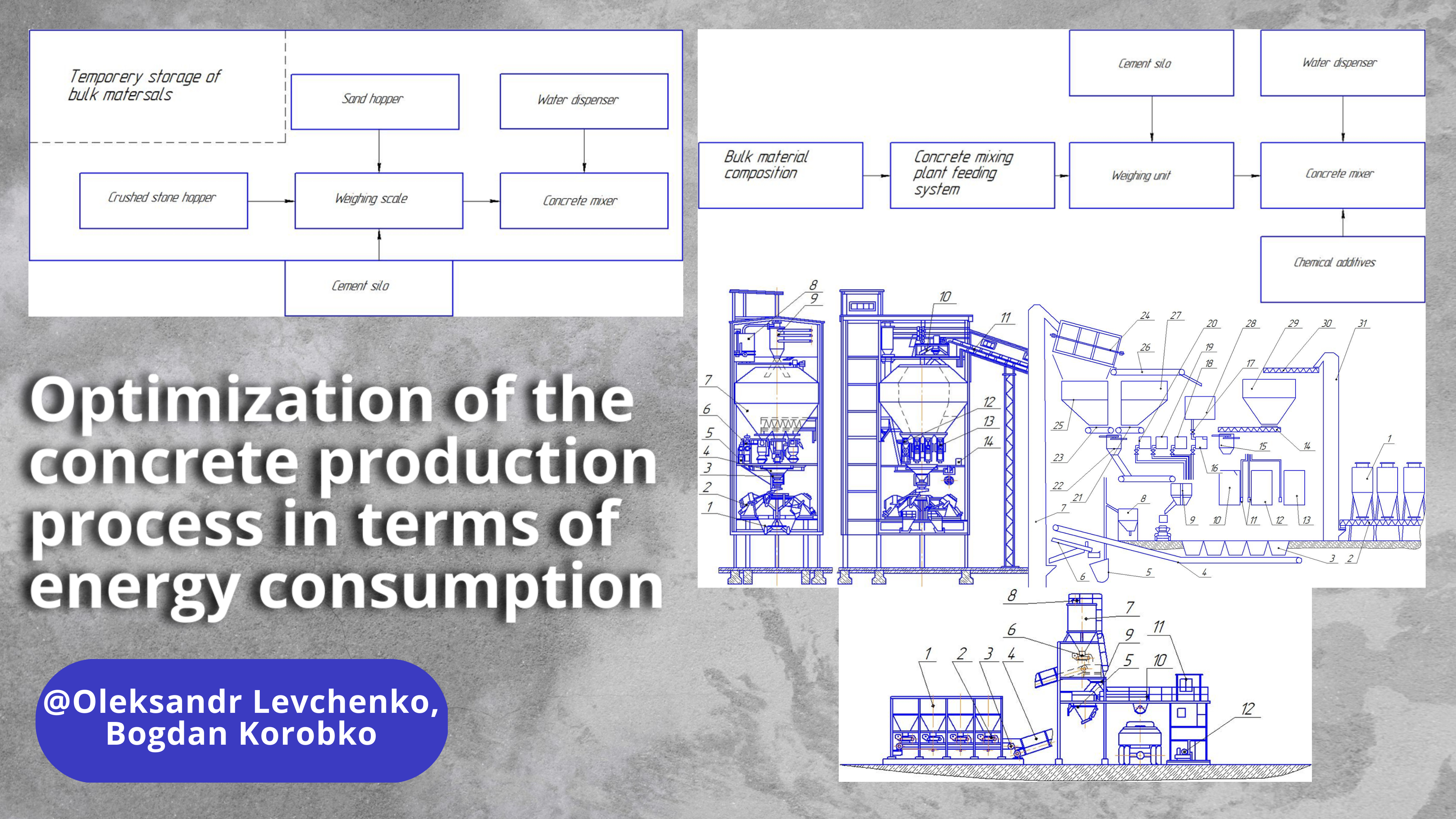

The object of study is the power supply system of a concrete mixing plant. The research made it possible to identify and eliminate the shortcomings of the existing power supply system in order to increase its energy efficiency and productivity. A new concept has been proposed, which provides for an individual arrangement of bins with isolated conveyors for each of them.

The study revealed a number of significant advantages of the proposed system, namely:

– separate conveyors for each hopper allow to optimize the routes of material movement, avoid unnecessary movements and reduce the load on the drives;

– the use of modern electric motors with high efficiency and other energy-saving components can further reduce energy consumption;

– due to the independent operation of each hopper, it is possible to load different materials in parallel, which reduces the time required to prepare a new portion of the concrete mixture;

– the absence of a common hopper reduces the risk of congestion and obstacles that can lead to equipment downtime;

– due to the independence of each hopper, different types of concrete mixtures can be prepared simultaneously.

However, there are some potential disadvantages and risks to consider before implementing a new system, including:

– the implementation of a new system may require significant investment in new equipment and installation;

– the number of system components increases, which may complicate its maintenance and repair;

– the efficient operation of the new system requires the development of special software and automation systems.

Despite some drawbacks, the introduction of a power supply system for a concrete mixing plant is a promising direction for the development of the machine-building and construction industry. The results of the study indicate the high efficiency of this technology and its economic feasibility in the long term.

References

- Worrell, E., Galitsky, C. (2008). Energy Efficiency Improvement and Cost Saving Opportunities for Cement Making. An ENERGY STAR Guide for Energy and Plant Managers. Office of Scientific and Technical Information (OSTI). https://doi.org/10.2172/927882

- Cantini, A., Leoni, L., De Carlo, F., Salvio, M., Martini, C., Martini, F. (2021). Technological Energy Efficiency Improvements in Cement Industries. Sustainability, 13 (7), 3810. https://doi.org/10.3390/su13073810

- Liu, H., Zhao, Q. (2023). Review on Energy Conservation of Construction Machinery for Pumping Concrete. Processes, 11 (3), 842. https://doi.org/10.3390/pr11030842

- Hnatov, A., Patlins, A., Arhun, S., Kunicina, N., Hnatova, H., Ulianets, O., Romanovs, A. (2020). Development of an unified energy-efficient system for urban transport. 2020 6th IEEE International Energy Conference (ENERGYCon), 248–253. https://doi.org/10.1109/energycon48941.2020.9236606

- Sadeghian, O., Moradzadeh, A., Mohammadi-Ivatloo, B., Abapour, M., Anvari-Moghaddam, A., Shiun Lim, J., Garcia Marquez, F. P. (2021). A comprehensive review on energy saving options and saving potential in low voltage electricity distribution networks: Building and public lighting. Sustainable Cities and Society, 72, 103064. https://doi.org/10.1016/j.scs.2021.103064

- Xiang, Q., Pan, H., Ma, X., Yang, M., Lyu, Y., Zhang, X. et al. (2024). Impacts of energy-saving and emission-reduction on sustainability of cement production. Renewable and Sustainable Energy Reviews, 191, 114089. https://doi.org/10.1016/j.rser.2023.114089

- Radchenko, A., Radchenko, M., Mikielewicz, D., Pavlenko, A., Radchenko, R., Forduy, S. (2022). Energy Saving in Trigeneration Plant for Food Industries. Energies, 15 (3), 1163. https://doi.org/10.3390/en15031163

- Lee, D., Lin, C. (2024). Universal artificial intelligence workflow for factory energy saving: Ten case studies. Journal of Cleaner Production, 468, 143049. https://doi.org/10.1016/j.jclepro.2024.143049

- Lai, X., Dai, M., Rameezdeen, R. (2020). Energy saving based lighting system optimization and smart control solutions for rail transportation: Evidence from China. Results in Engineering, 5, 100096. https://doi.org/10.1016/j.rineng.2020.100096

- Nazarenko, I. I., Tumanska, O. V. (2004). Mashyny i ustatkuvannya pidpryyemstv budivelnykh materialiv: konstruktsiyi ta osnovy ekspluatatsiyi. Kyiv: Vyshcha shkola, 590.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Oleksandr Levchenko, Bogdan Korobko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.