Development and improvement of roll casting technologies for universal beam mills

DOI:

https://doi.org/10.15587/2706-5448.2024.320381Keywords:

universal beam mills, double-layer rolls, casting technology, heat treatment, bainite-martensitic matrixAbstract

The object of this research is the casting technology of double-layer rolls for universal beam mills (UBM). They are critically important components of the metallurgical industry, ensuring the production of beams, profiles, and other structural elements, widely used in construction, mechanical engineering, transport, energy, and other industries. Developing innovative approaches to manufacturing rolls is strategically important for strengthening Ukraine's production potential. Since one of the most problematic areas is the dependence on imported rolls, which leads to significant economic losses, logistical risks and restrictions on the country's technological independence. Existing domestic technologies do not always lead to achieving the necessary operational characteristics, such as wear and heat resistance, and durability, complicating the competitiveness of products on the international market.

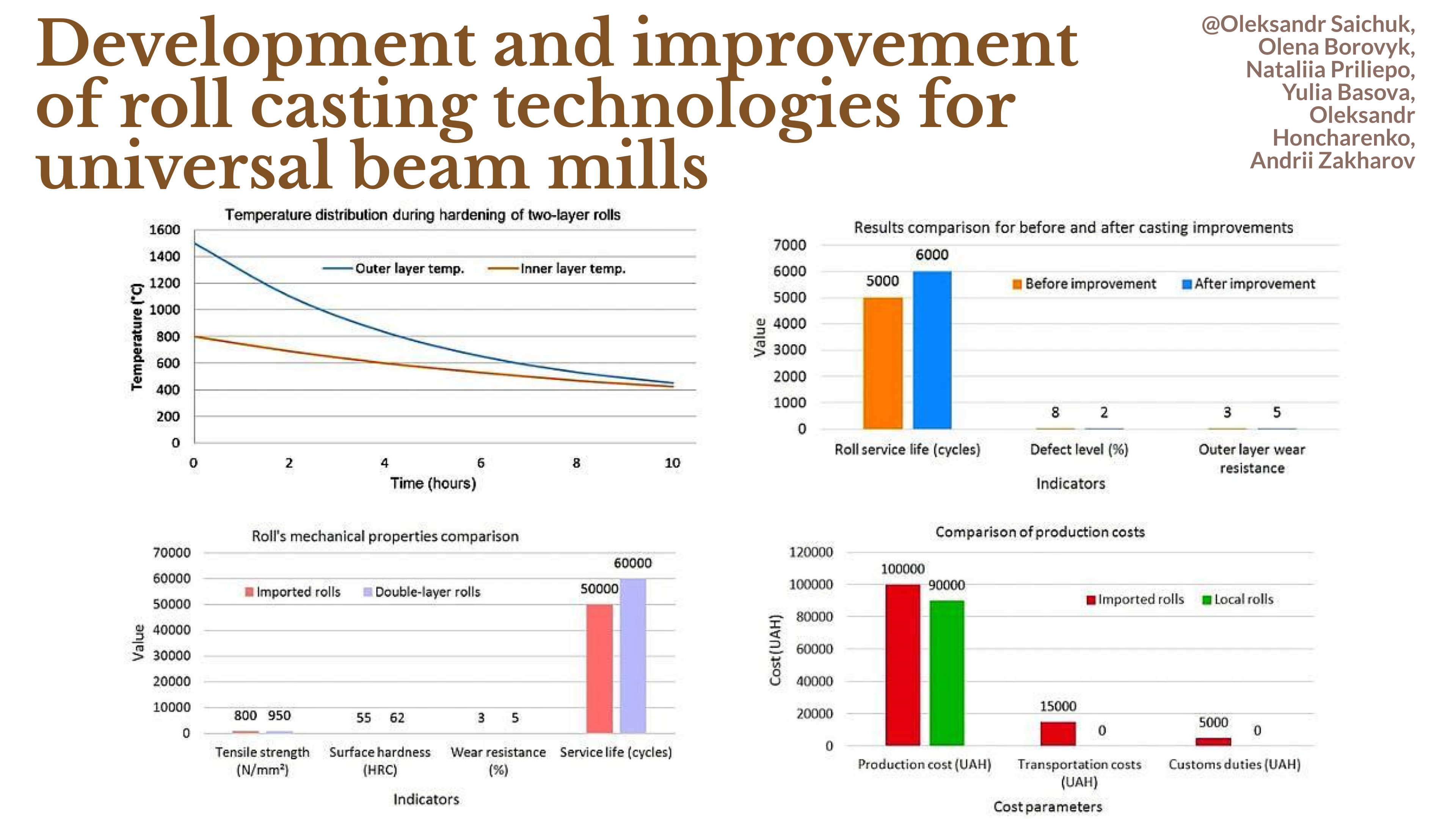

The work proposes an innovative technology for manufacturing two-layer rolls, using stationary casting molds, a bainite-martensitic outer layer structure, and optimization of temperature conditions. This provides high hardness, heat resistance, and wear resistance of the outer layer. The inner layer, made of high-plasticity materials, compensates for residual stresses and improves structural stability. The use of alloying elements (nickel, molybdenum, copper) in combination with mathematical modelling of temperature fields made it possible to reduce the number of structural defects, such as porosity and delamination while ensuring uniform connection of the layers. This is because the proposed technology combines modern approaches to alloying, heat treatment optimization, and high-tech modelling of temperature conditions during casting. A notable characteristic is the optimization of materials to withstand elevated mechanical and thermal stresses, complemented by an advanced casting mold design that enhances interlayer adhesion and minimizes the likelihood of defects. This facilitates the reliable performance of rolls under challenging operational conditions, characterized by elevated mechanical and thermal stresses. Compared with similar known solutions, the proposed technology increases the service life of rolls by 20–25 %, reduces repair and maintenance costs by 15–20 %, and increases the efficiency of production processes by reducing the frequency of equipment shutdowns.

References

- Vlasenko, T., Glowacki, S., Vlasovets, V., Hutsol, T., Nurek, T., Lyktei, V., Efremenko, V., Khrunyk, Y. (2024). Increasing Exploitation Durability of Two-Layer Cast Mill Rolls and Assessment of the Applicability of the XGBoost Machine Learning Method to Manage Their Quality. Materials, 17 (13), 3231. https://doi.org/10.3390/ma17133231

- Samokhval, V., Stasko, Y., Vasyliev, O. (2023). To the development of statistical models of wear rolls of long prodacts mills. Collection of Scholarly Papers of Dniprovsk State Technical University (Technical Sciences), 2 (43), 56–66. https://doi.org/10.31319/2519-2884.43.2023.5

- Bazarova, K. V. (2019). Udoskonalennya tekhnolohiyi ta obladnannya dlya prokatky dvotavrovykh balok na osnovi analizu formozminy metalu v rozriznykh kalibrakh. [Extended abstract of PhD thesis; Donbaska Derzhavna Mashinobudіvna Akademіia]. Available at: http://www.dgma.donetsk.ua/docs/nauka/12.105.01/bazarova/avtoreferat%20%20Bazarova%2007%2011%2019.pdf

- Ivanova, L. Kh., Bilyy, O. P., Osypenko, I. O. (2017). Vplyv sposobu lyttya prokatnykh valkiv na riven zalyshkovykh napruzhen u nykh. Visnyk Donbaskoyi derzhavnoyi mashynobudivnoyi akademiyi, 2 (41), 34–36. Available at: http://www.dgma.donetsk.ua/science_public/ddma/Herald_2(41)_2017/article/8.pdf

- Hlushkova, D., Volchuk, V., Marynenko, S. (2024). Optimization of mechanical properties of rolling rolls using multiparametric technologies. Applied Mechanics. Kyiv, 350–352. Available at: https://elartu.tntu.edu.ua/handle/lib/45541

- Arias-Ferreiro, G., Ares-Pernas, A., Dopico-García, M. S., Lasagabáster-Latorre, A., Abad, M.-J. (2020). Photocured conductive PANI/acrylate composites for digital light processing. Influence of HDODA crosslinker in rheological and physicochemical properties. European Polymer Journal, 136, 109887. https://doi.org/10.1016/j.eurpolymj.2020.109887

- Mohamed Nishath, P., Sekar, K. (2020). Boulevard for Effective Consumption of Power and Energy in Friction Stir Welding. Materials Today: Proceedings, 22, 1489–1498. https://doi.org/10.1016/j.matpr.2020.02.066

- Wang, Y. F., Hu, S. Y., Tian, Z. Q., Cheng, G. X. (2021). Corrigendum to “Quantitative assessment of the hydrogen induced cracking for 2.25Cr-1Mo-0.25V steel under electrochemical charging conditions”. Engineering Failure Analysis, 126, 105425. https://doi.org/10.1016/j.engfailanal.2021.105425

- Startt, J., Kustas, A., Pegues, J., Yang, P., Dingreville, R. (2022). Compositional effects on the mechanical and thermal properties of MoNbTaTi refractory complex concentrated alloys. Materials & Design, 213, 110311. https://doi.org/10.1016/j.matdes.2021.110311

- Atrens, A., Dietzel, W., Bala Srinivasan, P., Winzer, N., Bobby Kannan, M. (2011). Stress corrosion cracking (SCC) of magnesium alloys. Stress Corrosion Cracking. Woodhead Publishing, 341–380. https://doi.org/10.1533/9780857093769.3.341

- Mishchenko, A. V. (2020). Development of the ideology of calibrations of the tool for cold rolling of pipes from alloys based on titanium. Metal and Casting of Ukraine, 317-319 (10-12), 64–73. https://doi.org/10.15407/steelcast2019.10.064

- Schuppener, J., Benito, S., Weber, S. (2024). Correction: Increasing Energy Efficiency by Optimizing Heat Treatment Parameters for High-Alloyed Tool Steels. Journal of Materials Engineering and Performance, 33 (18), 9641–9641. https://doi.org/10.1007/s11665-024-09673-3

- Noha, V. O. (2024). Manufacturing castings from heat-resistant alloys for critical part. Casting Processes, 155 (1), 48–57. https://doi.org/10.15407/plit2024.01.048

- Dvulit, Z., Andrusiak, K. (2023). Challenges of the metallurgical industry of Ukraine in the current conditions. Management and Entrepreneurship in Ukraine: The Stages of Formation and Problems of Development, 202 (1), 261–268. https://doi.org/10.23939/smeu2023.01.261

- Khrychykov, V. Ye. (2024). Rozrobka metodiv usunennia usadkovykh defektiv u chavunnykh prokatnykh valkakh. Lytvo. Metalurhiia. Available at: https://repository.kpi.kharkov.ua/server/api/core/bitstreams/61aeb525-4252-4580-8534-2c2c428c02e8/content

- Yamshinskij, M., Byba, E., Minitskyi, A., Lukianenko, I., Bisyk, S., Hryniuk, V., Kyvhylo, B. (2024). Study of formation processes, structure and properties of porous frameworks. Casting Processes, 155 (1), 58–71. https://doi.org/10.15407/plit2024.01.058

- Marienko, B. V., Abramov, S. A., Bondarenko, S. V. (2021). Technological provision of quality ofshafs of twin-roll casting rolls. Teoriia i praktyka metalurhii, 4, 5–9. Available at: https://crust.ust.edu.ua/server/api/core/bitstreams/8171d134-a1f6-482a-bf9e-a5c83acef8c3/content

- Tarasov, V. K., Vodennikova, О. S., Vodennikov, S. А., Manidina, Ye. А. (2021). Molds preparation improving methods for steel casting. Metal and Casting of Ukraine, 29 (3), 28–35. https://doi.org/10.15407/steelcast2021.03.028

- Kryvosheiev, A. Ye., Bilai, H. Ye., Koteshev, M. P., Khrychikov, V. Ye. (2020). Development of scientific and technological foundations for the production of rolls for metallurgical, chemical, paper, and food industries. National Metallurgical Academy of Ukraine: Reports from the Annual Research Forum. Dnipro. Available at: https://nmetau.edu.ua/file/hrychikov.pdf

- Baiul, K. V. (2021). Development of scientific bases of creation of roll presses with the expanded technological possibilities and the increased service life. [National Metallurgical Academy of Ukraine; Extended abstract of Doctor’s thesis]. Available at: https://nmetau.edu.ua/file/avtoreferat_bayul_ukr.pdf

- Shevchenko, I. V., Kovalchuk, O. M. (2023). Enhancing the durability of mechanical equipment in the balancing system of rolling mill rolls. Bulletin of Lutsk National Technical University, 75–80.

- Ivanchenko, F. K., Hrebenyi, V. M., Shyriaiev, V. I. (1994). Rozrakhunky mashyn i mekhanizmiv prokatnykh tsekhiv. Kyiv: Vyshcha shkola, 455. https://i.twirpx.link/file/398313/

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Olexander Saychuk, Olena Borovyk, Nataliia Priliepo, Yulia Basova, Oleksandr Honcharenko, Andriy Zakharov

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.