Identification of temperature in cupola furnace based on the construction of the “slag composition – slag viscosity” model

DOI:

https://doi.org/10.15587/2706-5448.2025.322458Keywords:

cupola melting, slag composition, temperature regime in the cupola furnace, slag viscosity, temperature control loop in the cupola furnaceAbstract

The object of the study in the work is the temperature regime of melting in a cupola.

The existing problem is that due to the aggressive high-temperature environment, continuous measurement of the parameters of the internal environment in the working space of the cupola furnace is too difficult. Even with the implementation of such a possibility, errors of the first and second types may occur. This necessitates indirect control of the temperature regime, which could provide a solution to the identification problem – whether the control system is really operating in normal mode and meets the accuracy requirements, or whether there is a parametric failure along the corresponding control circuit.

The existence of the specified problem requires solutions related to the definition of criteria for evaluating the temperature regime, by which it would be possible to verify the reliable functioning of the melting control system.

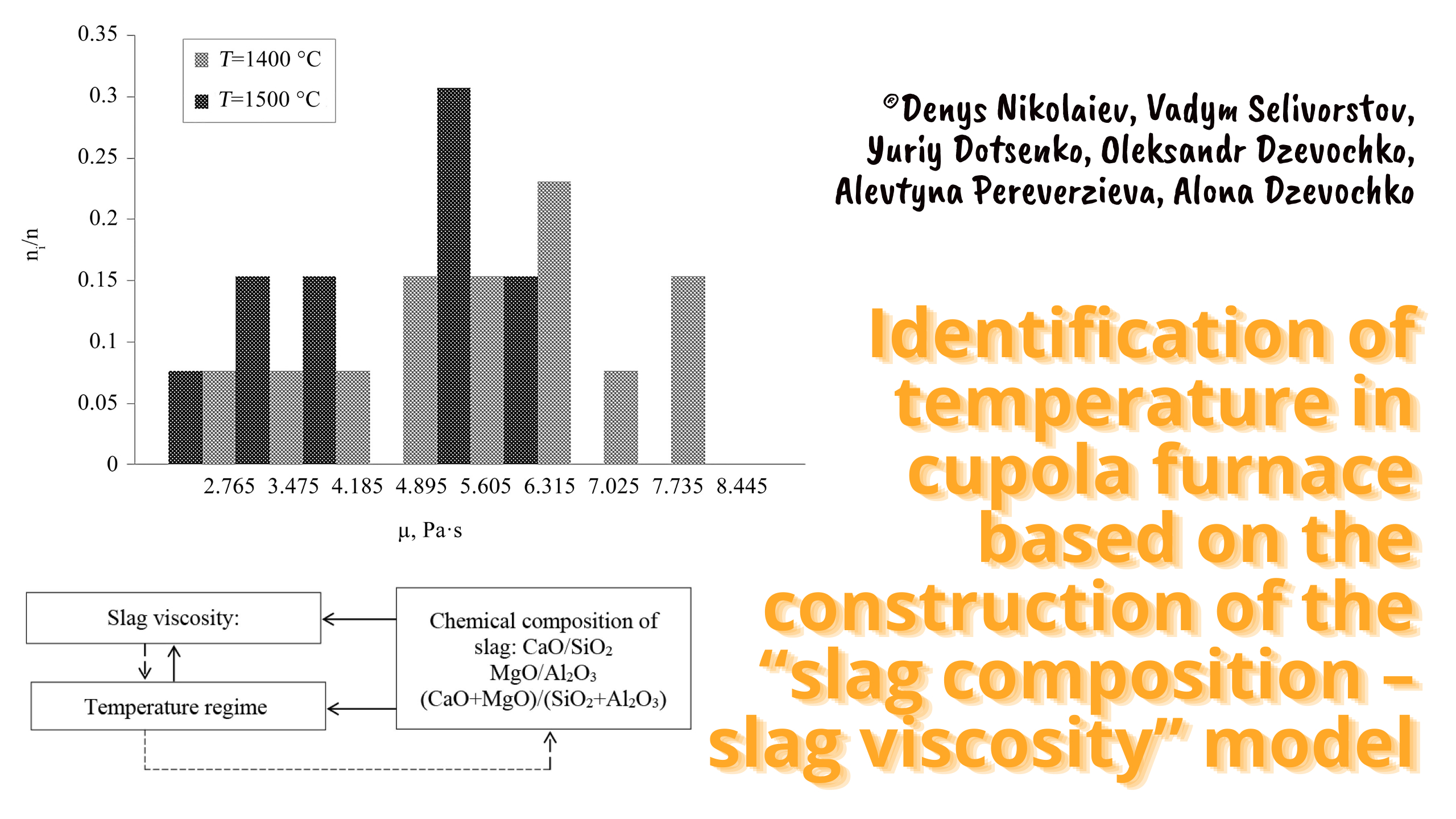

A criterion for evaluating the temperature regime of melting by the viscosity of the slag as a function of its composition is proposed, which allows identifying the temperature regime of melting with an accuracy of 96 %. This result is due to the proposed two-stage procedure, in which the first stage is the construction of mathematical models that describe the influence of the slag composition on the viscosity, and the second is the construction of a criterion based on the density distribution of the discriminant function for both temperature regimes. Using the obtained criterion also makes it possible to determine the areas of chemical compositions, by which the temperature regime can also be identified. The relationships between the variables for the identification procedure are presented in the form of a structural diagram. The proposed solutions will allow determining the quality of the functioning of the temperature control loop in the melting control system based on periodic control.

The presented study will be useful for machine-building enterprises that have foundries in their structure, where cast iron is smelted for the manufacture of castings.

References

- Demin, D. A. (2012). Synthesis of optimal temperature regulator of electroarc holding furnace bath. Scientific Bulletin of National Mining University, 6, 52–58.

- Demin, D. A. (2014). Mathematical description typification in the problems of synthesis of optimal controller of foundry technological parameters. Eastern-European Journal of Enterprise Technologies, 1 (4 (67)), 43–56. https://doi.org/10.15587/1729-4061.2014.21203

- Demin, D. A. (2014). Computer-integrated electric-arc melting process control system. Eastern-European Journal of Enterprise Technologies, 2 (9 (68)), 18–23. https://doi.org/10.15587/1729-4061.2014.23512

- Demin, D. (2017). Synthesis of optimal control of technological processes based on a multialternative parametric description of the final state. Eastern-European Journal of Enterprise Technologies, 3 (4 (87)), 51–63. https://doi.org/10.15587/1729-4061.2017.105294

- Demin, D. (2019). Development of «whole» evaluation algorithm of the control quality of «cupola – mixer» melting duplex process. Technology Audit and Production Reserves, 3 (1 (47)), 4–24. https://doi.org/10.15587/2312-8372.2019.174449

- Demin, D. (2023). Experimental and industrial method of synthesis of optimal control of the temperature region of cupola melting. EUREKA: Physics and Engineering, 2, 68–82. https://doi.org/10.21303/2461-4262.2023.002804

- Jopkiewicz, A., Podrzucki, C. (2007). Tendencies to the Improvement of the Cupola Process. Archives of foundry engineering, 13 (3), 61–70.

- Powell, W. L., Druschitz, A. P., Frost, J. (2008). Cupola Furnaces. Casting, 99–107. https://doi.org/10.31399/asm.hb.v15.a0005197

- Aristizábal, R. E., Pérez, P. A., Katz, S., Bauer, M. E. (2014). Studies of a Quenched Cupola. International Journal of Metalcasting, 8 (3), 13–22. https://doi.org/10.1007/bf03355586

- Ajah, S. A., Idorenyin, D., Nwokenkwo, U. C., Nwigwe, U. S., Ezurike, B. O. (2021). Thermal Analysis of a Conventional Cupola Furnace with Effects of Excess Air on the Flue Gases Specific Heat. Journal of Materials and Environmental Science, 12 (2), 192–204.

- Demin, D., Domin, O. (2021). Adaptive technology for constructing the kinetic equations of reduction reactions under conditions of a priori uncertainty. EUREKA: Physics and Engineering, 4, 14–29. https://doi.org/10.21303/2461-4262.2021.001959

- Demin, D. (2013). Adaptive modeling in problems of optimal control search termovremennoy cast iron. Eastern-European Journal of Enterprise Technologies, 6 (4 (66)), 31–37. https://doi.org/10.15587/1729-4061.2013.19453

- Luis, C. J., Álvarez, L., Ugalde, M. J., Puertas, I. (2002). A technical note cupola efficiency improvement by increasing air blast temperature. Journal of Materials Processing Technology, 120 (1-3), 281–289. https://doi.org/10.1016/s0924-0136(01)01053-6

- Jezierski, J., Janerka, K. (2011). Selected Aspects of Metallurgical and Foundry Furnace Dust Utilization. Polish Journal of Environmental Studies, 20 (1), 101–105.

- Isnugroho, K., Birawidha, D. C. (2018). The production of pig iron from crushing plant waste using hot blast cupola. Alexandria Engineering Journal, 57 (1), 427–433. https://doi.org/10.1016/j.aej.2016.11.004

- Larsen, E. D., Clark, D. E., Moore, K. L., King, P. E. (1997). Intelligent control of Cupola Melting. Available at: https://pdfs.semanticscholar.org/56c2/96af1d56d5cd963a5bcc38635142e5fa1968.pdf

- Moore, K. L., Abdelrahman, M. A., Larsen, E., Clark, D., King, P. (1998). Experimental control of a cupola furnace. Proceedings of the 1998 American Control Conference. ACC (IEEE Cat. No.98CH36207), 3816–3821. https://doi.org/10.1109/acc.1998.703360

- Nikolaiev, D. (2024). Construction of a cupola information profile for further modeling for the purpose of controlling melting processes. ScienceRise, 2, 00–00. https://doi.org/10.21303/2313-8416.2024.003674

- Demin, D., Frolova, L. (2024). Construction of a logical-probabilistic model of casting quality formation for managing technological operations in foundry production. EUREKA: Physics and Engineering, 6, 104–118. https://doi.org/10.21303/2461-4262.2024.003518

- Demin, D. (2020). Constructing the parametric failure function of the temperature control system of induction crucible furnaces. EUREKA: Physics and Engineering, 6, 19–32. https://doi.org/10.21303/2461-4262.2020.001489

- Stanovska, I., Duhanets, V., Prokopovych, L., Yakhin, S. (2021). Classification rule for determining the temperature regime of induction gray cast iron. EUREKA: Physics and Engineering, 1, 60–66. https://doi.org/10.21303/2461-4262.2021.001604

- Penziev, P., Lavryk, Y. (2023). Diagnostics of the temperature condition of cast iron melting in induction furnaces by the content of SiO2 and CaO in slag. ScienceRise, 1, 14–20. https://doi.org/10.21303/2313-8416.2024.003558

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Denys Nikolaiev, Vadym Selivorstov, Yuriy Dotsenko, Oleksandr Dzevochko, Pereverzieva Pereverzieva, Alona Dzevochko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.