Determination of the influence of the thermostabilizer content on the cyclic processing of polyvinyl chloride

DOI:

https://doi.org/10.15587/2706-5448.2025.322887Keywords:

thermal degradation, rheometric analysis, plastogram, tensile strength, impact strength, melt flow index, extrusionAbstract

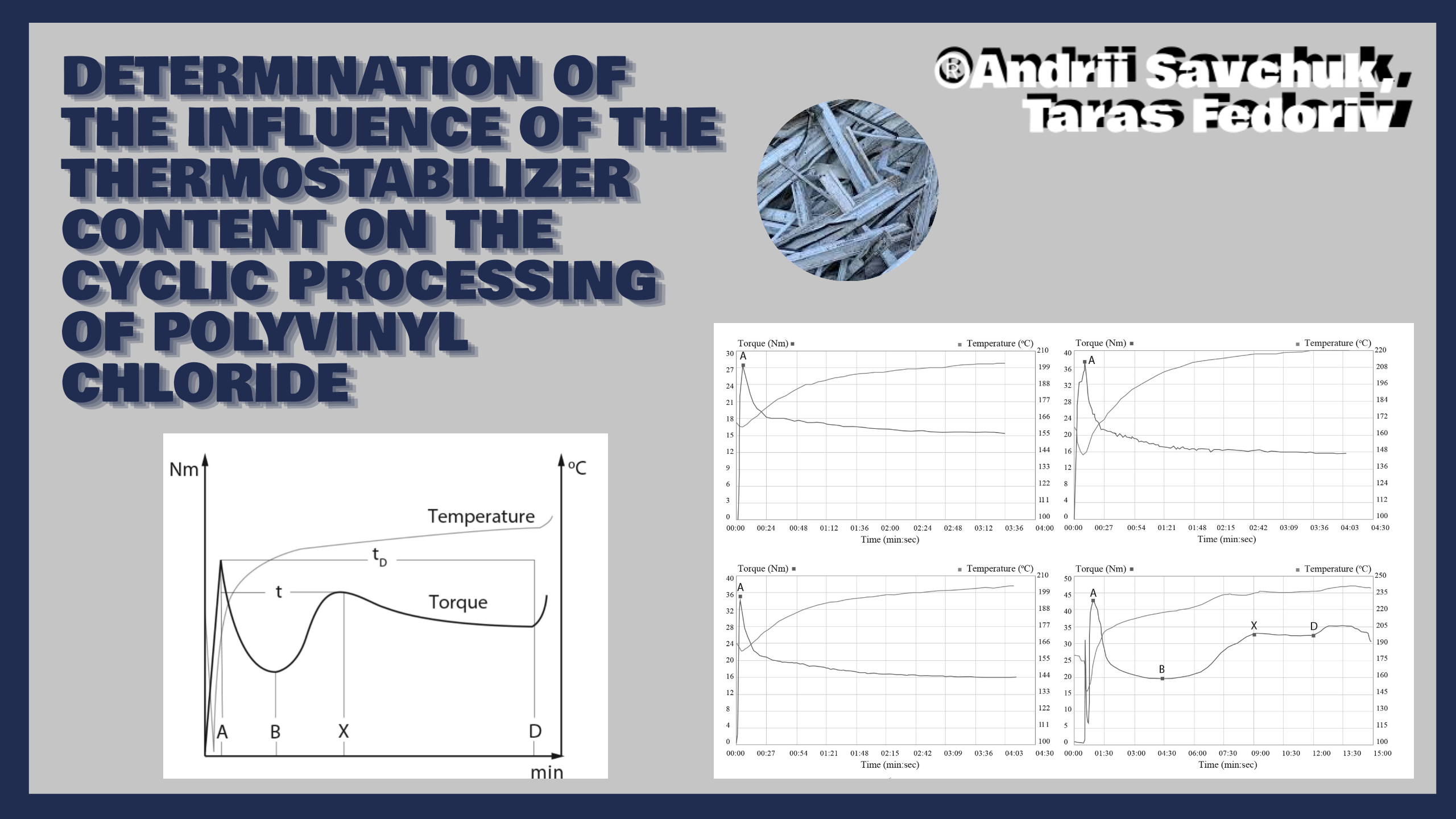

The object of the study is the process of cyclic recycling of polyvinyl chloride (PVC). The main problem of multiple recycling of polyvinyl chloride is poor thermal stability. This problem is associated with insufficient stabilization of polyvinyl chloride at the stage of manufacturing the initial product. Usually, such products are difficult to recycle, since the content of additives in polyvinyl chloride is designed for one-time manufacturing of products and does not provide for repeated cyclic recycling. In addition, it may be necessary to modify the PVC composition to obtain the characteristics necessary for a new application. The thermal stability of polyvinyl chloride can be improved by various methods of physical modification. One of the key methods is the introduction of a stabilizer in a rational amount. To solve the problems set in the work, PVC composites with an adjustable stabilizer content from 2 to 5 mass parts were manufactured. The manufactured composites were recycled up to 5 times. At each cycle of PVC composites processing, thermal stability and melting point were determined using the RM-200C Hapro rheometer plastograph (Harbin University of Science and Technology Harbin Technology Co. Ltd, China). Mechanical properties were also determined on a tensile machine according to ISO 527-2:2012, Charpy impact strength according to ISO 179 and ASTM D256, and melt flow index according to ISO 1133:199.

The study found that increasing the stabilizer content by only 1–2 parts by mass from its base concentration of 3 parts by mass increases the life of the PVC composite by 1.5–2 times. A stabilizer content of 4–5 parts by mass allows maintaining sufficiently stable physical and mechanical characteristics of the PVC composite during 5 processing cycles.

As a result of the research, a PVC formulation suitable for cyclic processing was proposed, which is achieved by introducing 4–5 mass parts of the stabilizer at the stage of primary PVC production. This allows maintaining the mechanical characteristics of the material, valuable for the final application during multiple processing compared to typical PVC composites used on the market for the production of window profiles.

References

- Ait‐Touchente, Z., Khellaf, M., Raffin, G., Lebaz, N., Elaissari, A. (2023). Recent advances in polyvinyl chloride (PVC) recycling. Polymers for Advanced Technologies, 35 (1). https://doi.org/10.1002/pat.6228

- Mathews, G. (2024). PVC: production, properties and uses. CRC Press, 400. https://doi.org/10.1201/9781003575863

- PVC Chemical Resistance Guide. Polyvinyl Chloride (PVC) (2020). IPEX: Oakville.

- Brockmann, W., Geiß, P. L., Klingen, J., Schröder, K. B. (2009). Adhesive Bonding: Materials, Applications and Technology. Weinheim: WILEY-VCH Verlag GmbH & Co. KGaA. https://doi.org/10.1002/9783527623921

- Wypych, G. (2020). PVC Degradation and Stabilization. Toronto: ChemTec Publishing. https://doi.org/10.1016/C2019-0-00335-4

- Wypych, G. (2020). PVC Formulary. Toronto: ChemTec Publishing. https://doi.org/10.1016/c2019-0-00367-6

- Cousins, K. (2002). Polymers in Building and Construction. Shawbury: Rapra Technology LTD.

- Edo, G. I., Ndudi, W., Ali, A. B. M., Yousif, E., Zainulabdeen, K., Onyibe, P. N. et al. (2024). Poly(vinyl chloride) (PVC): an updated review of its properties, polymerization, modification, recycling, and applications. Journal of Materials Science, 59 (47), 21605–21648. https://doi.org/10.1007/s10853-024-10471-4

- Unar, I. N., Soomro, S. A., Aziz, S. (2010). Effect of Various Additives on the Physical Properties of Polyvinylchloride Resin. Pakistan Journal of Analytical & Environmental Chemistry, 11 (2), 44–50.

- Ciacci, L., Passarini, F., Vassura, I. (2017). The European PVC cycle: In-use stock and flows. Resources, Conservation and Recycling, 123, 108–116. https://doi.org/10.1016/j.resconrec.2016.08.008

- Arnold, J. C., Maund, B. (1999). The properties of recycled PVC bottle compounds. 2: Reprocessing stability. Polymer Engineering & Science, 39 (7), 1242–1250. Portico. https://doi.org/10.1002/pen.11511

- Arnold, J. C., Maund, B. (1999). The properties of recycled PVC bottle compounds. 1: Mechanical performance. Polymer Engineering & Science, 39 (7), 1234–1241. https://doi.org/10.1002/pen.11510

- Chantreux, M., Ricard, D., Asia, L., Rossignol, S., Wong-Wah-Chung, P. (2021). Additives as a major source of radiolytic organic byproducts of polyvinyl chloride (PVC). Radiation Physics and Chemistry, 188, 109671. https://doi.org/10.1016/j.radphyschem.2021.109671

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Andrii Savchuk, Taras Fedoriv

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.