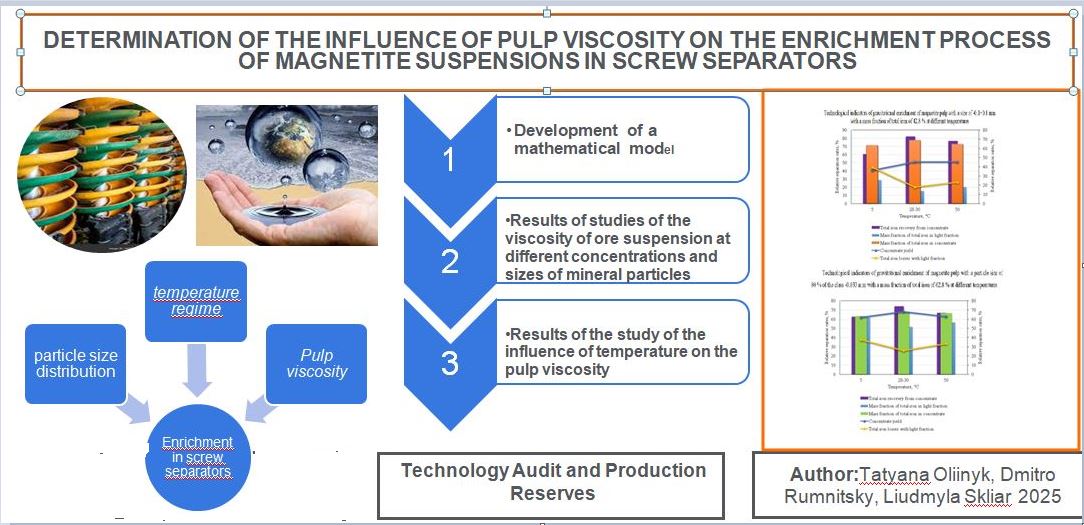

Determination of the influence of pulp viscosity on the enrichment process of magnetite suspensions in screw separators

DOI:

https://doi.org/10.15587/2706-5448.2025.323268Keywords:

suspension viscosity, screw separator, magnetite pulp, particle shape, solid concentration, temperature regimesAbstract

The object of research is the process of enrichment of magnetite suspensions in screw separators, taking into account the particle size distribution, the compressibility of the liquid in the interparticle space, and the shape of the particles, which allows to assess the influence of these factors on the value of the effective viscosity of the suspension. The viscosity of the suspension is one of the properties for ore suspensions with a wide range of particle sizes and different concentrations of solids in operations and products. It determines the nature of the movement of the liquid, the state of the solids in it – the degree of its loosening, the difficulty of sedimentation, and energy consumption for transportation during the enrichment of magnetite ores in screw separators. The studies were conducted using analytical and experimental methods. It was experimentally established that the dependence of the viscosity of the pulp suspension on the particle size in the range of less than 1 mm has an inversely proportional relationship. At a volume concentration of solids in the pulp from 10 to 70 %, the viscosity of the suspension increases with a decrease in the volume concentration of the minus 0.1 mm class from 100 to 20 %. It has been established that at temperature regimes from 28 to 50 °C, the viscosity of magnetite suspensions increases with a decrease in the grinding fineness in different ways. The viscosity of magnetite suspensions depends on the mass fraction of solids: material with a fineness of 80 % minus 0.044 mm increases the viscosity of the suspension at concentrations above 40 %, and at a fineness of 80 % minus 0.031 mm – above 60 %.

The obtained scientific result, in the form of a calculation of the effective viscosity of the pulp, is based on a theory that takes into account the influence of particle size as a function of their average effective diameter, concentration and shape of suspended particles. From a practical point of view, the research results allow to develop optimal conditions for gravitational enrichment of magnetite ores in screw separators and avoid additional losses of valuable components.

References

- Russel, W. B. (1980). Review of the Role of Colloidal Forces in the Rheology of Suspensions. Journal of Rheology, 24 (3), 287–317. https://doi.org/10.1122/1.549564

- Krieger, I. M. (1972). Rheology of monodisperse latices. Advances in Colloid and Interface Science, 3 (2), 111–136. https://doi.org/10.1016/0001-8686(72)80001-0

- Hoffman, R. L. (1974). Discontinuous and dilatant viscosity behavior in concentrated suspensions. II. Theory and experimental tests. Journal of Colloid and Interface Science, 46 (3), 491–506. https://doi.org/10.1016/0021-9797(74)90059-9

- Buscall, R. (1994). An effective hard-sphere model of the non-Newtonian viscosity of stable colloidal dispersions: Comparison with further data for sterically stabilised latices and with data for microgel particles. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 83 (1), 33–42. https://doi.org/10.1016/0927-7757(93)02652-u

- Krieger, I. M.; Buscall, R., Corner, T., Stageman, J. (Ed.) (1985). Rheology of polymer colloids. Polymer colloids. L. N.Y., 6, 219.

- Quemada, D. (1978). Rheology of concentrated disperse systems III. General features of the proposed non-newtonian model. Comparison with experimental data. Rheologica Acta, 17 (6), 643–653. https://doi.org/10.1007/bf01522037

- Chou, K., Lee, L. (1989). Effect of Dispersants on the Rheological Properties and Slip Casting of Concentrated Alumina Slurry. Journal of the American Ceramic Society, 72 (9), 1622–1627. https://doi.org/10.1111/j.1151-2916.1989.tb06293.x

- Craban, S., Parzonka, W., Havlik, V. (1988). Non-Newtonian behavior of kaolin suspensions. Progress and Trends in Rheology II. New York: Springer-Verlag, 325–328. https://doi.org/10.1007/978-3-642-49337-9_111

- Wildemuth, C. R., Williams, M. C. (1984). Viscosity of suspensions modeled with a shear-dependent maximum packing fraction. Rheologica Acta, 23 (6), 627–635. https://doi.org/10.1007/bf01438803

- Doraiswamy, D., Mujumdar, A. N., Tsao, I., Beris, A. N., Danforth, S. C., Metzner, A. B. (1991). The Cox-Merz rule extended: A rheological model for concentrated suspensions and other materials with a yield stress. Journal of Rheology, 35 (4), 647–685. https://doi.org/10.1122/1.550184

- Pilov, P. I. (2003). Hravitatsiina separatsiia korysnykh kopalyn. Dnipropetrovsk: Natsionalnyi hirnychyi universytet, 123.

- Barnes, H. A. (2000). A Handbook of Elementary Rheology. Institute of Non-Newtonian Fluid Mechanics. University of Wales. Aberystwyth, 200.

- Hunter, R. J. (1995). Foundations of Colloid Science. Vol. 2. Oxford, 922.

- Krykh, H. B. (2007). Osoblyvosti zastosuvannia reolohichnykh modelei neniutonivskykh ridyn. Visnyk Natsionalnoho universytetu “Lvivska politekhnika”. Teploenerhetyka. Inzheneriia dovkillia. Avtomatyzatsiia, 581, 71–82. Available at: https://vlp.com.ua/files/11_46.pdf

- Stentsel, Y. I., Saldan, Y. R., Pavlov, S. V., Kozhemiako, V. P. (2013). Reolohichni modeli molekuly vody ta yii spoluk. Optoelectronic Information-Energy Technologies, 19 (1), 202–212. Available at: https://oeipt.vntu.edu.ua/index.php/oeipt/article/view/161

- Barnes, H. A., Walters, K. (1985). The yield stress myth? Rheologica Acta, 24 (4), 323–326. https://doi.org/10.1007/bf01333960

- Barnes, H. A. (1992). The Yield Stress Myth?’ Revisited. Theoretical and Applied Rheology, 576–578. https://doi.org/10.1016/b978-0-444-89007-8.50248-3

- Tadros, Th. F.; Tadros, Th. F. (Ed.) (1987). Introduction. Solid. Liquid dispersions. London.

- Goodwin, J. W. (1987). The rheology of colloidal dispersions. Solid. Liquid dispersions. London, 199.

- Tadros, Th. F. (1986). Control of the properties of suspensions. Colloids and Surfaces, 18 (2-4), 137–173. https://doi.org/10.1016/0166-6622(86)80311-0

- Goodwin, J. W. (1982). Some Uses of Rheology. Coll. Sci. in Coll. Dispers. Royal Society of Chemistry, 165.

- Krieger, I. M. (1972). Rheology of monodisperse latices. Advances in Colloid and Interface Science, 3 (2), 111–136. https://doi.org/10.1016/0001-8686(72)80001-0

- Smith, T. L., Bruce, C. A. (1979). Intrinsic viscosities and other rheological properties of flocculated suspensions of nonmagnetic and magnetic ferric oxides. Journal of Colloid and Interface Science, 72 (1), 13–26. https://doi.org/10.1016/0021-9797(79)90176-0

- Han, C. D. (1980). Multiphase Flow in Polymer Processing. Rheology, 121–128. https://doi.org/10.1007/978-1-4684-3746-1_19

- Marrucci, G., Denn, M. M. (1985). On the viscosity of a concentrated suspension of solid spheres. Rheologica Acta, 24 (3), 317–320. https://doi.org/10.1007/bf01332611

- Zhdanov, V. H., Starkov, V. M. (1998). Vyznachennia efektyvnoi viazkosti kontsentrovanykh sus-penzii. Koloidnyi zhurnal, 60 (6), 771–774.

- Kuzmichev, V. E. (1989). Zakony i formuly fizyky. Kyiv: Naukova dumka, 864. Available at: https://www.at.alleng.org/d/phys/phys614.htm

- Betchelor, D. (1980). Vplyv brounivskoho rukhu na seredniu napruhu v suspenzii sferskykh chastynok. Mekhanika. Nove u zarubizhnii nautsi. Hidrodynamichne vzaiemodiia chastynok u suspenziiakh, 22, 124–153.

- Kondratiev, A. S., Naumova, E. A. (2006). Shvydkist stysloho osadzhennia bimodalnoi sumishi sferychnykh chastynok v niutonovii ridyni. Teoret. osnov. khim. Tekhnol., 40 (4), 417–423.

- Iatskov, M. V., Bulenkova, N. M., Mysina, O. I. (2016). Fizychna i koloidna khimiia. Rivne: NUVHP, 164.

- Gadala‐Maria, F., Acrivos, A. (1980). Shear‐Induced Structure in a Concentrated Suspension of Solid Spheres. Journal of Rheology, 24 (6), 799–814. https://doi.org/10.1122/1.549584

- Biletskyi, V. S., Oliinyk, T. A., Smyrnov, V. O., Skliar, L. V. (2020). Osnovy tekhniky ta tekhnolohii zbahachennia korysnykh kopalyn. Kyiv, 618.

- Oliinyk, T., Sklyar, L., Kushniruk, N., Holiver, N., Tora, B. (2023). Assessment of the Efficiency of Hematite Quartzite Enrichment Technologies. Inżynieria Mineralna, 1 (1), 33–44. https://doi.org/10.29227/im-2023-01-04

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Tatуana Oliinyk, Dmytro Rumnytskyi, Liudmyla Skliar

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.