Determination of the influence of the number of profile holes on the efficiency indicators of hemp seed crusher impellers

DOI:

https://doi.org/10.15587/2706-5448.2025.323745Keywords:

hemp seeds, seed kernels, centrifugal dehulling, impeller, impeller profile holes, dehulling efficiencyAbstract

The object of the research is technological processes, seeds and kernels of industrial hemp, centrifugal dehullers, dehuller impellers.

The research is aimed at increasing the efficiency of centrifugal dehulling of industrial hemp seeds by determining the influence of the number of profile holes in the impellers.

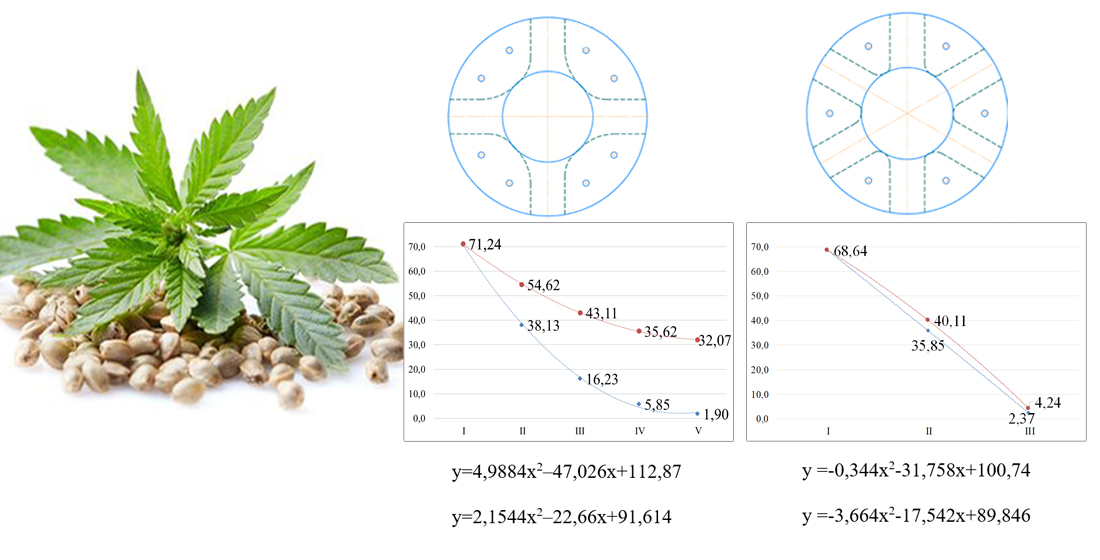

Two variants of the impeller design were developed and tested: with four and six profile holes. The research was conducted on seeds of the “Glesia” variety under stable processing conditions, including optimal humidity (8.4 %) and standardized wheel rotation parameters (6000±200 rpm).

According to the research results, it was established:

– an impeller with four profile holes in five dehulling cycles enabled a total kernel yield of 34.81 %. Under such conditions, the bulk of the seeds were dehulled in the first three cycles;

– the impeller with six profile holes made it possible to ensure a total kernel yield of 34.48 % in three dehulling cycles. Under these conditions, a significant part of the kernels was separated in the first two cycles.

According to the results of the analysis of the dehulling indicators, it was noted:

– in the first two cycles, the wheel with six holes separated up to 29.71 % of the kernels, and the wheel with four holes - up to 22.02 %;

– the use of the design of the wheel with six holes reduced the remains of undehulled seeds after the third cycle to 4.24 % of the initial mass, while the wheel with four holes – up to 16.23 %.

The advantages of the centrifugal dehulling method, which is based on the principle of converting kinetic energy into impact, were noted. This made it possible to separate the shells from the kernels without prior calibration of industrial hemp seeds.

The research results demonstrated the advantages of the improved design, which includes an impeller with six profile holes, and the prospects of its use to increase the productivity of industrial hemp seed dehulling.

References

- Farinon, B., Molinari, R., Costantini, L., Merendino, N. (2020). The Seed of Industrial Hemp (Cannabis sativa L.): Nutritional Quality and Potential Functionality for Human Health and Nutrition. Nutrients, 12 (7), 1935. https://doi.org/10.3390/nu12071935

- Alonso-Esteban, J. I., Pinela, J., Ćirić, A., Calhelha, R. C., Soković, M., Ferreira, I. C. F. R. et al. (2022). Chemical composition and biological activities of whole and dehulled hemp (Cannabis sativa L.) seeds. Food Chemistry, 374, 131754. https://doi.org/10.1016/j.foodchem.2021.131754

- Oseyko, M., Sova, N., Yefimov, V., Petrachenko, D. (2024). Chemical composition of seeds of industrial Ukrainian hemp varieties. Ukrainian Food Journal, 13 (3), 542–556. https://doi.org/10.24263/2304-974x-2024-13-3-8

- Sheichenko, V., Petrachenko, D. (2024). Dehulling of Industrial Hemp Seeds with High-Performance Mechanisms. National Interagency Scientific and Technical Collection of Works. Design, Production and Exploitation of Agricultural Machines, 54, 55–62. https://doi.org/10.32515/2414-3820.2024.54.55-62

- Montero, L., Ballesteros-Vivas, D., Gonzalez-Barrios, A. F., Sánchez-Camargo, A. del P. (2023). Hemp seeds: Nutritional value, associated bioactivities and the potential food applications in the Colombian context. Frontiers in Nutrition, 9. https://doi.org/10.3389/fnut.2022.1039180

- Kabir, A., Fedele, O. (2018). A Review of Shelling, Threshing, De-Hulling and Decorticating Machines. Open Access Journal of Agricultural Research, 3 (1). https://doi.org/10.23880/oajar-16000148

- Baker, B. (2015). Dehulling ancient grains: economic considerations and equipment. Available at: https://eorganic.org/node/13028 Last accessed: 08.01.2025

- Manjeet, P., Pragi, S., Kanak, D., Anil, B. (2017). Pod Shelling Machines-A Review. International Journal of Agricultural Science and Research (IJASR), 7, 321–326.

- Sharma, V., Pradhan, R. C., Naik, S. N., Bhatnagar, N., Singh, S. (2013). Evaluation of a centrifugal impaction-type decorticator for shelling tung fruits. Industrial Crops and Products, 43, 126–131. https://doi.org/10.1016/j.indcrop.2012.06.046

- Complex Oilseed Processing. Available at: https://www.farmet.cz/en/complex-oilseed-processing

- Li, A., Jia, F., Chu, Y., Han, Y., Li, H., Sun, Z. et al. (2023). Simulation of the movement of rice grains in a centrifugal huller by discrete element method and the influence of blade shape. Biosystems Engineering, 236, 54–70. https://doi.org/10.1016/j.biosystemseng.2023.10.013

- Bernik, R., Stajnko, D., Demšar, I. (2020). Comparison of the Kernel Quality of Different Walnuts (Juglans regia L.) Varieties Shelled with Modified Centrifugal Sheller. Erwerbs-Obstbau, 62 (2), 213–220. https://doi.org/10.1007/s10341-020-00473-2

- Sheichenko, V., Petrachenko, D., Koropchenko, S., Rogovskii, I., Gorbenko, O., Volianskyi, M., Sheichenko, D. (2024). Substantiating the rational parameters and operation modes for the hemp seed centrifugal dehuller. Eastern-European Journal of Enterprise Technologies, 2 (1 (128)), 34–48. https://doi.org/10.15587/1729-4061.2024.300174

- Lachuga, Yu. F., Ibyatov, R. I., Ziganshin, B. G., Shogenov, Yu. H., Dmitriev, A. V. (2020). Simulation of the Grain Trajectory along Working Bodies of the Pneumatic Mechanical Dehuller. Russian Agricultural Sciences, 46 (5), 534–538. https://doi.org/10.3103/s1068367420050110

- Cao, B., Jia, F., Zeng, Y., Han, Y., Meng, X., Xiao, Y. (2018). Effects of rotation speed and rice sieve geometry on turbulent motion of particles in a vertical rice mill. Powder Technology, 325, 429–440. https://doi.org/10.1016/j.powtec.2017.11.048

- Baker, A., Dwyer-Joyce, R., Briggs, C., Brockfeld, M. (2012). Effect of different rubber materials on husking dynamics of paddy rice. Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology, 226 (6), 516–528. https://doi.org/10.1177/1350650111435601

- Khodabakhshian, R., Bayati, M. R. (2011). Investigation into the Effects of Impeller Vane Patterns and Pistachio Nut Size on Hulling Efficiency of Pistachio Nuts using A Centrifugal Huller. Journal of Food Processing & Technology, 2 (3). https://doi.org/10.4172/2157-7110.1000115

- Nasinnia silskohospodarskykh kultur. Metody vyznachennia yakosti (2004). DSTU 4138-2002. Kyiv: Derzhspozhyvstandart Ukrainy.

- Khailis, H. A., Konovaliuk, D. M. (1992). Osnovy proektuvannia i doslidzhennia silskohospodarskykh mashyn. Kyiv: NMK VO, 320.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Viktor Sheichenko, Dmytro Petrachenko, Anatolii Lytvynenko, Oleksandra Bilovod, Denys Sheichenko, Yurii Brodovych, Vitaliy Shevchuk, Misha Shevchuk

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.