Setting the parameters of thermal destruction of fire-resistant wood

DOI:

https://doi.org/10.15587/2706-5448.2025.323845Keywords:

protective agents, fire resistance, volatile products, mass loss, surface treatment, protection efficiencyAbstract

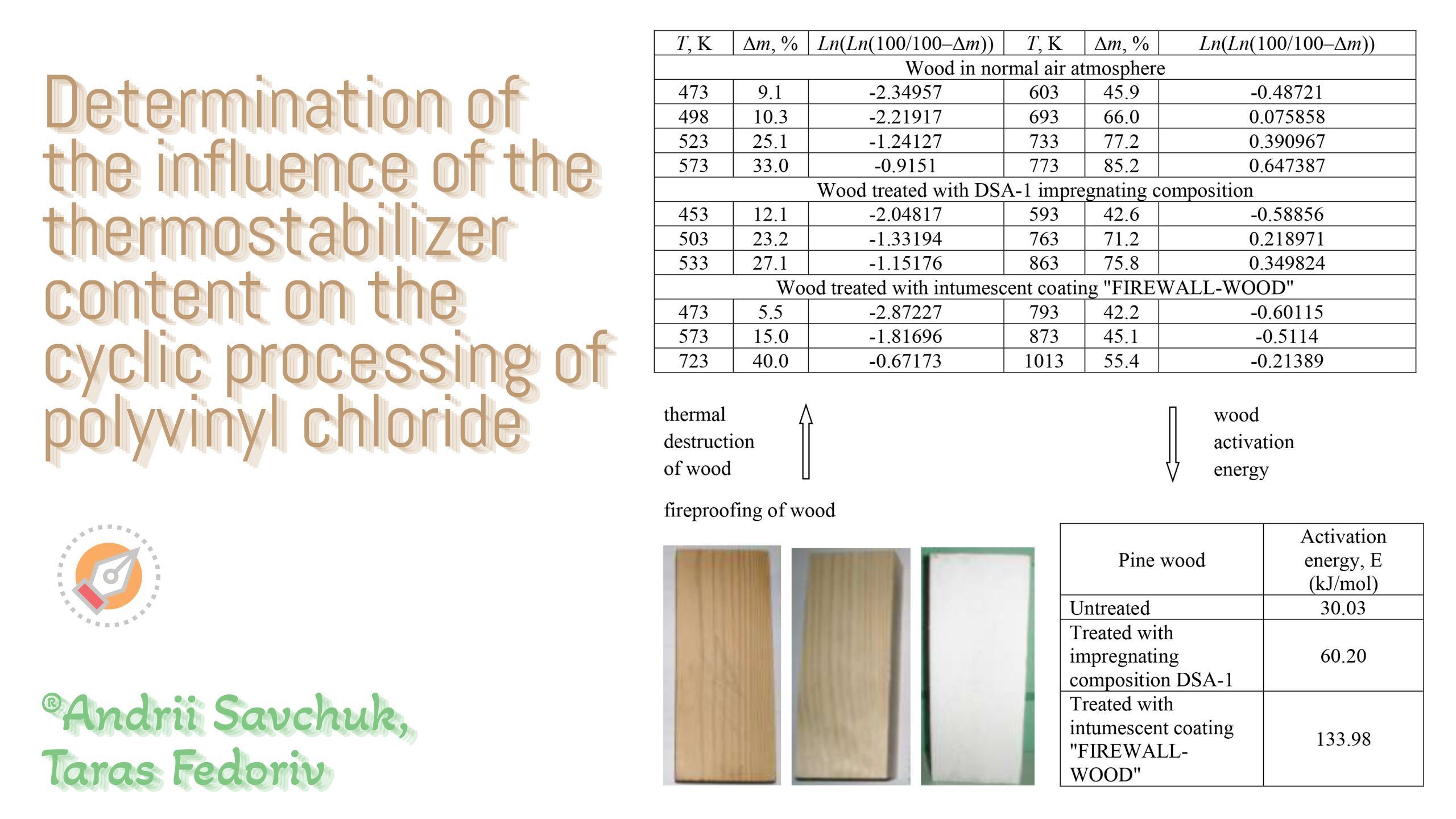

The problem of using wood is to ensure resistance to high-temperature flame and application technology. Therefore, the object of research was to change the parameters of thermal destruction of wood during fire protection by impregnation and intumescent coating. It has been proven that for wood treated by impregnation, the destruction processes slow down, so the mass loss is reduced by 3–5 times, the process increases in the region of higher temperatures with a significant coke residue. As for wood treated with intumescent coating, in the temperature range of 200–300 °C, pentaerythritol begins to decompose with the formation of aldehydes and a foam coke center is formed. The beginning of intensive mass loss coincides with the temperature of 320–330 °C, on which the sublimation peak of melamine is superimposed, starting at a temperature of 330 °C, which ends at a temperature of more than 420 °C. The obtained activation energy of wood is 30.03 kJ/mol, treatment of wood with impregnating agents increases the activation energy during its thermal decomposition by more than two times, and treatment with an intumescent coating by more than 4.4 times. After pyrolysis of wood treated with flame retardants, the mixtures of destruction products differ significantly in the content of carbon dioxide, nitrogen and the amount of combustible gases. Thus, for wood treated with the composition DSA-1, the amount of nitrogen increased by more than 46 times, and the amount of combustible gases decreased by more than 3 times. An even greater difference was recorded during treatment of wood with an intumescent coating. In particular, it was found that the amount of combustible gases decreased by more than 4 times, and the amount of nitrogen increased by more than 56 times. The practical significance lies in the fact that the results obtained were taken into account when developing a reactive coating. Thus, there are grounds to argue about the possibility of directed regulation of the wood protection process through the use of coatings capable of forming a protective layer on the surface.

References

- Chernukha, A., Chernukha, A., Kovalov, P., Savchenko, A. (2021). Thermodynamic Study of Fire-Protective Material. Materials Science Forum, 1038, 486–491. https://doi.org/10.4028/www.scientific.net/msf.1038.486

- Lee, Y. X., Wang, W., Lei, Y., Xu, L., Agarwal, V., Wang, C., Yeoh, G. H. (2025). Flame-retardant coatings for wooden structures. Progress in Organic Coatings, 198, 108903. https://doi.org/10.1016/j.porgcoat.2024.108903

- Kochubei, V., Mykhalichko, B., Lavrenyuk, H. (2021). Elaboration, thermogravimetric analysis, and fire testing of a new type of wood‐sawdust composite materials based on epoxy–amine polymers modified with copper(II) hexafluorosilicate. Fire and Materials, 46 (3), 587–594. https://doi.org/10.1002/fam.3008

- Xiao, X., Xiao, X., Liu, S., Li, Y., Li, Y., Li, M. (2024). Green and efficient flame-retardant nanocomposites from hydroxyapatite nanosheets modified porous wood. Industrial Crops and Products, 219, 119105. https://doi.org/10.1016/j.indcrop.2024.119105

- Koparipek-Arslan, N., Kaynak-Uraz, E., Senses, E. (2024). Dynamically bonded cellulose nanocrystal hydrogels: Structure, rheology and fire prevention performance. Carbohydrate Polymers, 334, 122013. https://doi.org/10.1016/j.carbpol.2024.122013

- Tuble, K. A. Q., Omisol, C. J. M., Abilay, G. Y., Tomon, T. R. B., Aguinid, B. J. M., Dumancas, G. G. et al. (2024). Synergistic effect of phytic acid and eggshell bio-fillers on the dual-phase fire-retardancy of intumescent coatings applied on cellulosic substrates. Chemosphere, 358, 142226. https://doi.org/10.1016/j.chemosphere.2024.142226

- Rodriguez-Melendez, D., Vest, N. A., Kolibaba, T. J., Quan, Y., Zhang, Z., Iverson, E. T. et al. (2024). Boron-based polyelectrolyte complex nanocoating for fire protection of engineered wood. Cellulose, 31 (5), 3083–3094. https://doi.org/10.1007/s10570-024-05773-4

- Wang, X., Wang, B., Sun, J., Yu, L., Yang, G., Guo, H. (2023). Flame‐retardant composite derived from polyurethane/wood‐fiber. Fire and Materials, 48 (2), 273–285. https://doi.org/10.1002/fam.3182

- Kumar, S., Shukla, S. K. (2023). Synergistic evolution of flame-retardant hybrid structure of poly vinyl alcohol, starch and kaolin for coating on wooden substrate. Journal of Polymer Research, 30 (2). https://doi.org/10.1007/s10965-023-03463-6

- Zhan, W., Ma, Z., Du, D., Sun, Z., Li, L., Gu, Z. et al. (2022). Effects of bagasse fiber as the renewable environmentally friendly material on the properties of the waterborne intumescent fireproof coating. Journal of Applied Polymer Science, 139 (34). https://doi.org/10.1002/app.52815

- Mihăilă, A., Danu, M., Ibănescu, C., Anghel, I., Şofran, I.-E., Balanescu, L. V. et al. (2021). Thermal characterization and rheological behavior of some varnishes and paints used for wood protection. International Journal of Environmental Science and Technology, 19 (7), 6299–6314. https://doi.org/10.1007/s13762-021-03579-6

- Khadiran, T., Jasmani, L., Rusli, R. (2022). Application of Nanomaterials for Wood Protection. Emerging Nanomaterials, 179–196. https://doi.org/10.1007/978-3-031-17378-3_7

- Broido, A. (1969). A simple, sensitive graphical method of treating thermogravimetric analysis data. Journal of Polymer Science Part A-2: Polymer Physics, 7 (10), 1761–1773. https://doi.org/10.1002/pol.1969.160071012

- Tsapko, Y., Tsapko, А. (2017). Establishment of the mechanism and fireproof efficiency of wood treated with an impregnating solution and coatings. Eastern-European Journal of Enterprise Technologies, 3 (10 (87)), 50–55. https://doi.org/10.15587/1729-4061.2017.102393

- Shestak, Ia. (1987). Teoriia termicheskogo analiza. Mir, 1987. 455.

- Tsapko, J., Tsapko, А. (2017). Simulation of the phase transformation front advancement during the swelling of fire retardant coatings. Eastern-European Journal of Enterprise Technologies, 2 (11 (86)), 50–55. https://doi.org/10.15587/1729-4061.2017.73542

- Tsapko, Y., Tsapko, А., Likhnyovskyi, R., Sukhanevych, M., Zapolskiy, L., Illiuchenko, P., Bedratiuk, O. (2024). Establishing patterns in reducing fire-dangerous properties of sip panels fire-protected with reactive coating. Eastern-European Journal of Enterprise Technologies, 1 (10 (127)), 47–54. https://doi.org/10.15587/1729-4061.2024.298266

- Tsapko, Y., Likhnyovskyi, R., Tsapko, А., Bielikova, K., Poteriaiko, S., Illiuchenko, P., Bondarenko, O. (2023). Determining patterns in the formation of an insulation layer of foam coke when protecting concrete against fire by reactive coating. Eastern-European Journal of Enterprise Technologies, 6 (10 (126)), 65–72. https://doi.org/10.15587/1729-4061.2023.293685

- Kochubei, V., Kozyar, N., Lavrenyuk, H., Mykhalichko, B. (2024). Metal-Coordinated Epoxy-Amine Composition with Reduced Fire Risk: Elaboration, Thermal and Ignition Resistance. Periodica Polytechnica Chemical Engineering, 68 (3), 446–453. https://doi.org/10.3311/ppch.36543

- Mykhalichko, B., Lavrenyuk, H. (2022). Flame Protection Technologies for Wood: Developing and Testing for Fire of Timbers with a Flame-retardant Coating Based on the Epoxy-amine Composite Modified by Copper(II) Hexafluorosilicate. Periodica Polytechnica Chemical Engineering, 66 (2), 304–312. https://doi.org/10.3311/ppch.19050

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Yuriy Tsapko, Kateryna Pushkarova, Аleksii Tsapko, Oksana Berdnyk, Olga Bondarenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.