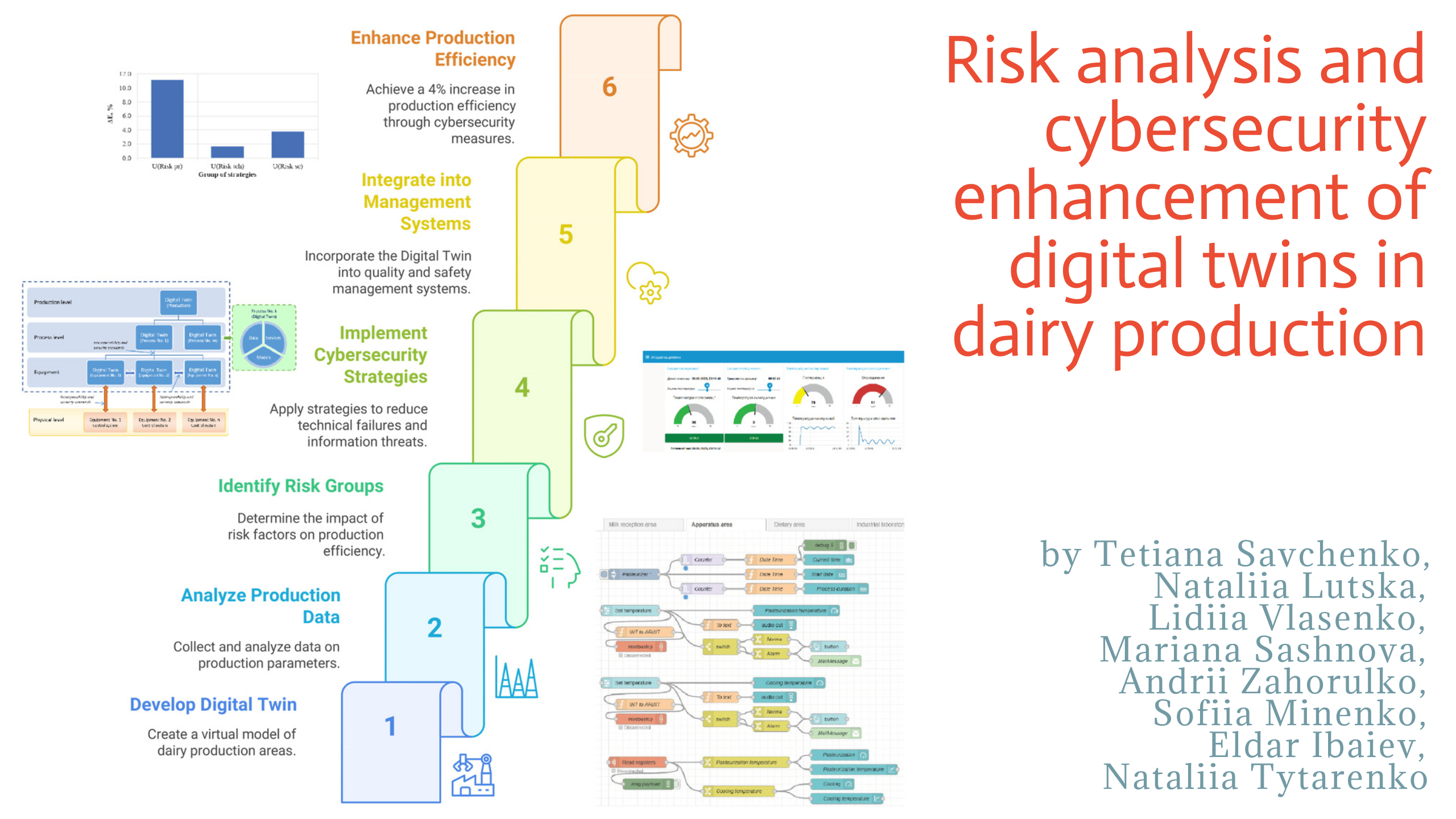

Risk analysis and cybersecurity enhancement of Digital Twins in dairy production

DOI:

https://doi.org/10.15587/2706-5448.2025.325422Keywords:

Digital Twins, industrial Internet of Things, monitoring, control and threat modeling, technological risks, food industry, information systems securityAbstract

The object of research is technological and technical processes that affect the effectiveness of developing a system with Digital Twins and ensuring cyber security using the example of the dairy industry.

The work is aimed at solving the problems in the sector of a comprehensive system for monitoring production processes with the possibility of early detection of deviations and potential threats. This, in turn, can lead to a decrease in product quality and an increase in cyber security risks.

During the implementation of the research, Digital Twins of the main technological areas was developed using the example of a dairy enterprise, namely: receiving, apparatus and dietary departments. This approach provides for the collection and analysis of data on production parameters (pasteurization temperature, level in tanks, etc.), and also integrates the results of laboratory control. It was found that technological risks have the greatest impact on the effectiveness of the functioning of production processes, and security risks directly account for 35 % of the total threat structure. This is partly due to one of the main problems in the sector of insufficient data protection and possible external interference, including during cyber attacks. In addition, the analysis identified three risk groups (a total of 13 factors), which further allowed to determine their impact on the efficiency of production as a whole. This, in turn, allowed to draw a preliminary conclusion that the use of cybersecurity risk management strategies reduces the likelihood of technical failures and information threats at an industrial enterprise. The results of modeling Digital Twins of the main technological areas using the example of a dairy enterprise showed that the implementation of strategies from the security risk group increases the efficiency of the project by 4%. The results obtained can be used to increase the level of cybersecurity and monitor production processes in the dairy industry and other agro-industrial sectors. The developed Digital Twins can be integrated into quality and safety management systems for food production, in particular, for enterprises operating in conditions of increased risks of cyber threats.

Supporting Agency

- The work was carried out within the framework of the state budget theme of the young scientists' project No. 1-24-25 of the State Budgetary Fund “Development of hardware and technological solutions for the production of multi-purpose polycomponent organic semi-finished products and food products in conditions of military operations and post-war reconstruction of the country”.

References

- Hassoun, A., Ait-Kaddour, A., Abu-Mahfouz, A. M., Rathod, N. B., Bader, F., Barba, F. J. et al. (2022). The fourth industrial revolution in the food industry – Part I: Industry 4.0 technologies. Critical Reviews in Food Science and Nutrition, 63 (23), 6547–6563. https://doi.org/10.1080/10408398.2022.2034735

- Pozzi, R., Rossi, T., Secchi, R. (2021). Industry 4.0 technologies: critical success factors for implementation and improvements in manufacturing companies. Production Planning & Control, 34 (2), 139–158. https://doi.org/10.1080/09537287.2021.1891481

- Jones, D., Snider, C., Nassehi, A., Yon, J., Hicks, B. (2020). Characterising the Digital Twin: A systematic literature review. CIRP Journal of Manufacturing Science and Technology, 29, 36–52. https://doi.org/10.1016/j.cirpj.2020.02.002

- Han, S. (2020). A review of smart manufacturing reference models based on the skeleton meta-model. Journal of Computational Design and Engineering, 7 (3), 323–336. https://doi.org/10.1093/jcde/qwaa027

- Digital Twins for Industrial Applications (2020). Definition, Business Values, Design Aspects, Standards And Use Cases. An Industrial Internet Consortium White Paper. Available at: https://www.iiconsortium.org/pdf/IIC_Digital_Twins_Industrial_Apps_White_Paper_2020-02-18.pdf

- Pal, S., Jadidi, Z. (2021). Analysis of Security Issues and Countermeasures for the Industrial Internet of Things. Applied Sciences, 11 (20), 9393. https://doi.org/10.3390/app11209393

- Khanam, S., Ahmedy, I. B., Idna Idris, M. Y., Jaward, M. H., Bin Md Sabri, A. Q. (2020). A Survey of Security Challenges, Attacks Taxonomy and Advanced Countermeasures in the Internet of Things. IEEE Access, 8, 219709–219743. https://doi.org/10.1109/access.2020.3037359

- Latif, S., Idrees, Z., Huma, Z., Ahmad, J. (2021). Blockchain technology for the industrial Internet of Things: A comprehensive survey on security challenges, architectures, applications, and future research directions. Transactions on Emerging Telecommunications Technologies, 32 (11). https://doi.org/10.1002/ett.4337

- Abosata, N., Al-Rubaye, S., Inalhan, G., Emmanouilidis, C. (2021). Internet of Things for System Integrity: A Comprehensive Survey on Security, Attacks and Countermeasures for Industrial Applications. Sensors, 21 (11), 3654. https://doi.org/10.3390/s21113654

- Mendez Mena, D., Papapanagiotou, I., Yang, B. (2018). Internet of things: Survey on security. Information Security Journal: A Global Perspective, 27 (3), 162–182. https://doi.org/10.1080/19393555.2018.1458258

- Corallo, A., Lazoi, M., Lezzi, M., Luperto, A. (2022). Cybersecurity awareness in the context of the Industrial Internet of Things: A systematic literature review. Computers in Industry, 137, 103614. https://doi.org/10.1016/j.compind.2022.103614

- Jhanjhi, N., Humayun, M., N. Almuayqil, S. (2021). Cyber Security and Privacy Issues in Industrial Internet of Things. Computer Systems Science and Engineering, 37 (3), 361–380. https://doi.org/10.32604/csse.2021.015206

- Shepherd, C., Arfaoui, G., Gurulian, I., Lee, R. P., Markantonakis, K., Akram, R. N. et al. (2016). Secure and Trusted Execution: Past, Present, and Future – A Critical Review in the Context of the Internet of Things and Cyber-Physical Systems. 2016 IEEE Trustcom/BigDataSE/ISPA, 168–177. https://doi.org/10.1109/trustcom.2016.0060

- Peter, O., Pradhan, A., Mbohwa, C. (2023). Industrial internet of things (IIoT): opportunities, challenges, and requirements in manufacturing businesses in emerging economies. Procedia Computer Science, 217, 856–865. https://doi.org/10.1016/j.procs.2022.12.282

- The Business Viewpoint of Securing the Industrial Internet (2016). Executive Overview. Industrial Internet Consortium. Available at: https://hub.iiconsortium.org/securing-industrial-internet-exec-overview

- Caindec, K., Buchheit, M., Zarkout, B., Schrecker, S., Hirsch, F., Dungana, I. et al. (2023). Industry Internet of Things Security Framework (IISF). An Industry IoT Framework Publication. Available at: https://www.iiconsortium.org/wp-content/uploads/sites/2/2023/06/IISF-Version-2.pdf

- Soori, M., Arezoo, B., Dastres, R. (2023). Digital twin for smart manufacturing, A review. Sustainable Manufacturing and Service Economics, 2, 100017. https://doi.org/10.1016/j.smse.2023.100017

- Liu, X., Jiang, D., Tao, B., Xiang, F., Jiang, G., Sun, Y. et al. (2023). A systematic review of digital twin about physical entities, virtual models, twin data, and applications. Advanced Engineering Informatics, 55, 101876. https://doi.org/10.1016/j.aei.2023.101876

- Attaran, M., Celik, B. G. (2023). Digital Twin: Benefits, use cases, challenges, and opportunities. Decision Analytics Journal, 6, 100165. https://doi.org/10.1016/j.dajour.2023.100165

- Leng, J., Wang, D., Shen, W., Li, X., Liu, Q., Chen, X. (2021). Digital twins-based smart manufacturing system design in Industry 4.0: A review. Journal of Manufacturing Systems, 60, 119–137. https://doi.org/10.1016/j.jmsy.2021.05.011

- Botín-Sanabria, D. M., Mihaita, A.-S., Peimbert-García, R. E., Ramírez-Moreno, M. A., Ramírez-Mendoza, R. A., Lozoya-Santos, J. de J. (2022). Digital Twin Technology Challenges and Applications: A Comprehensive Review. Remote Sensing, 14 (6), 1335. https://doi.org/10.3390/rs14061335

- Vlasenko, L., Lutska, N., Zaiets, N., Korobiichuk, I., Hrybkov, S. (2022). Core Ontology for Describing Production Equipment According to Intelligent Production. Applied System Innovation, 5 (5), 98. https://doi.org/10.3390/asi5050098

- Vlasenko, L. O., Lutska, N. M., Zaiets, N. A., Shyshak, A. V., Savchuk, O. V. (2022). Domain ontology development for condition monitoring system of industrial control equipment and devices. Radio Electronics, Computer Science, Control, 1, 157. https://doi.org/10.15588/1607-3274-2022-1-16

- Lyu, Z., Fridenfalk, M. (2024). Digital twins for building industrial metaverse. Journal of Advanced Research, 66, 31–38. https://doi.org/10.1016/j.jare.2023.11.019

- NodeREDGuidUKR. Node-RED manual in Ukrainian. Available at: https://pupenasan.github.io/NodeREDGuidUKR/base/

- Hoffmann, R., Napiórkowski, J., Protasowicki, T., Stanik, J. (2020). Risk based approach in scope of cybersecurity threats and requirements. Procedia Manufacturing, 44, 655–662. https://doi.org/10.1016/j.promfg.2020.02.243

- Nehrey, M., Voronenko, I., Salem, A.-B. M. (2022). Cybersecurity Assessment: World and Ukrainian Experience. 2022 12th International Conference on Advanced Computer Information Technologies (ACIT), 335–340. https://doi.org/10.1109/acit54803.2022.9913081

- Wu, H., Ji, P., Ma, H., Xing, L. (2023). A Comprehensive Review of Digital Twin from the Perspective of Total Process: Data, Models, Networks and Applications. Sensors, 23 (19), 8306. https://doi.org/10.3390/s23198306

- Cains, M. G., Flora, L., Taber, D., King, Z., Henshel, D. S. (2021). Defining Cyber Security and Cyber Security Risk within a Multidisciplinary Context using Expert Elicitation. Risk Analysis, 42 (8), 1643–1669. https://doi.org/10.1111/risa.13687

- Vlasenko, L. O., Lutska, N. M., Zaiets, N. A., Savchenko, T. V., Rudenskiy, A. A. (2024). Development of applied ontology for the analysis of digital criminal crime. Radio Electronics, Computer Science, Control, 4, 184. https://doi.org/10.15588/1607-3274-2023-4-17

- Kolosok, S., Lyeonov, S., Voronenko, I., Goncharenko, O., Maksymova, J., Chumak, O. (2022). Sustainable Business Models and IT Innovation: The Case of the REMIT. Journal of information technology management, 14, 147–156. https://doi.org/10.22059/JITM.2022.88894

- Voronenko, I., Klymenko, N., Nahorna, O. (2022). Challenges to Ukraine’s Innovative Development in a Digital Environment. Management and Production Engineering Review, 13 (4), 48–58. https://doi.org/10.24425/mper.2022.142394

- Systema avtomatyzatsii diietdilnytsi Yahotynskoho maslozavodu (2010). Available at: https://www.copa-data.com.ua/proekty/sistema-avtomatizatsiji-dietdilnitsi-yagotinskogo-maslozavodu

- Zahorulko, An., Zagorulko, Al., Minenko, S., Bozhydai, I. (2024). Scientific and practical justification of innovative approaches to production of multicomponent semi-finished products for food products in the conditions of food security of the country. Food Production: Innovative Technological Solutions. Kharkiv: PC TECHNOLOGY CENTER, 64–91. https://doi.org/10.15587/978-617-7319-99-2.ch3

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 Tetiana Savchenko, Nataliia Lutska, Lidiia Vlasenko, Mariana Sashnova, Andrii Zahorulko, Sofiia Minenko, Eldar Eldar, Nataliia Tytarenko

This work is licensed under a Creative Commons Attribution 4.0 International License.

The consolidation and conditions for the transfer of copyright (identification of authorship) is carried out in the License Agreement. In particular, the authors reserve the right to the authorship of their manuscript and transfer the first publication of this work to the journal under the terms of the Creative Commons CC BY license. At the same time, they have the right to conclude on their own additional agreements concerning the non-exclusive distribution of the work in the form in which it was published by this journal, but provided that the link to the first publication of the article in this journal is preserved.